Novel mica tape winding device

A technology of winding device and mica tape, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc. The effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

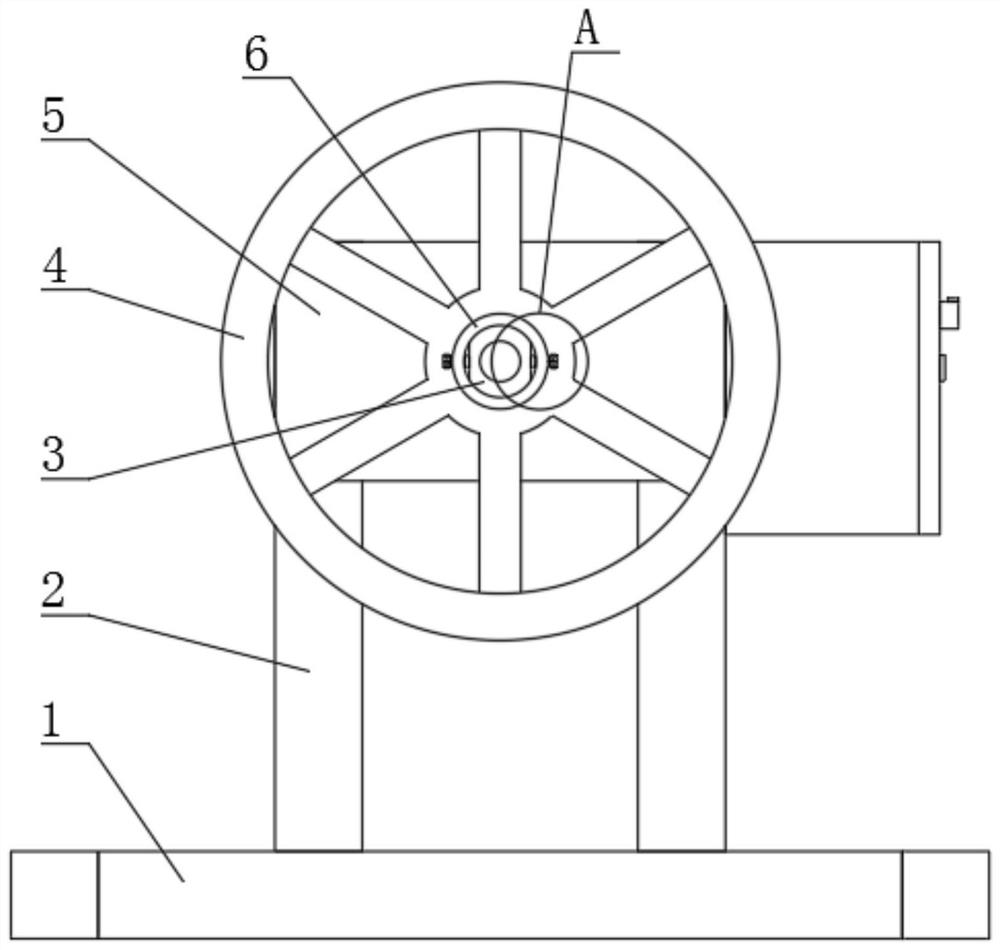

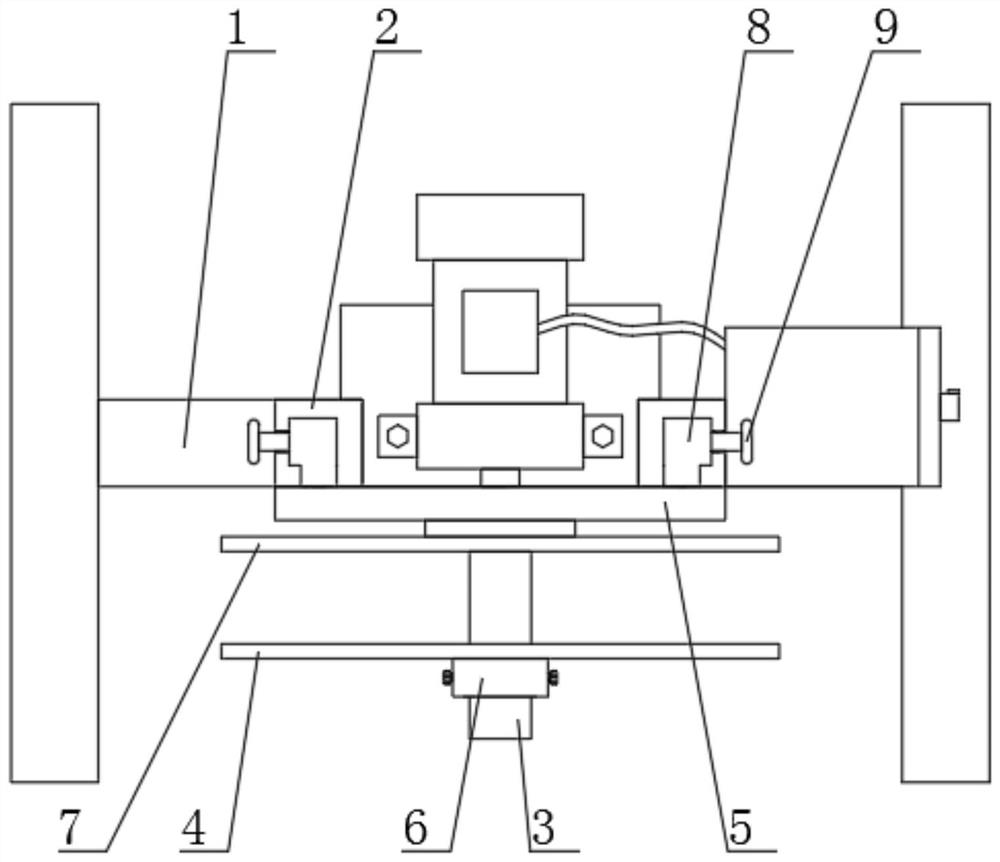

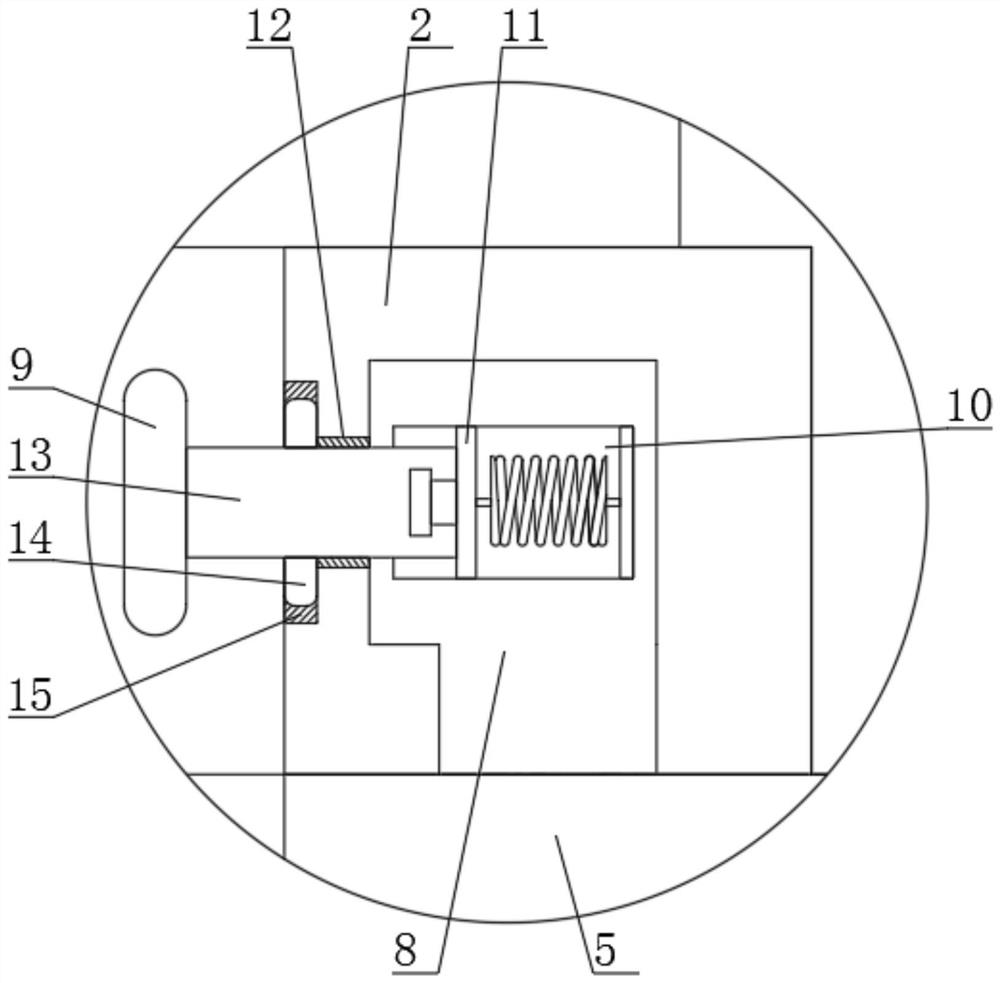

[0023] see Figure 1 to Figure 3 , the present invention provides a technical solution: a novel mica tape winding device, comprising a frame 1 and a substrate 5 arranged on the top of the frame 1, and the front surface of the substrate 5 is provided with a rotating shaft 3, and the surface of the rotating shaft 3 is provided with The inner baffle 7 and the outer baffle 4, the inner baffle 7 is fixedly connected with the rotating shaft 3, the outer baffle 4 is directly sleeved on the surface of the rotating shaft 3, the inner baffle 7 and the outer baffle 4 form a winding reel assembly, and the frame The top of 1 is symmetrically fixed with two struts 2 by bolts, the rear surface of the base plate 5 is symmetrically provided with two L-shaped sliders 8 by welding, and the interior of the struts 2 is provided with a matching L-shaped slider 8. L-shaped chute, the L-shaped slider 8 is inside the L-shaped chute, so that the L-shaped slider 8 can slide inside the L-shaped chute, th...

Embodiment 2

[0028] see Figure 1 to Figure 5 , the present invention provides a technical solution: a novel mica tape winding device, comprising a frame 1 and a substrate 5 arranged on the top of the frame 1, and the front surface of the substrate 5 is provided with a rotating shaft 3, and the surface of the rotating shaft 3 is provided with The inner baffle 7 and the outer baffle 4, the inner baffle 7 is fixedly connected with the rotating shaft 3, the outer baffle 4 is directly sleeved on the surface of the rotating shaft 3, the inner baffle 7 and the outer baffle 4 form a winding reel assembly, and the frame The top of 1 is symmetrically fixed with two struts 2 by bolts, the rear surface of the base plate 5 is symmetrically provided with two L-shaped sliders 8 by welding, and the interior of the struts 2 is provided with a matching L-shaped slider 8. L-shaped chute, the L-shaped slider 8 is inside the L-shaped chute, so that the L-shaped slider 8 can slide inside the L-shaped chute, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com