Composite probe, converter sublance and molten steel measuring method

A molten steel and converter technology, applied in the direction of manufacturing converters, etc., can solve the problems that affect the measurement success rate, the measurement data cannot be correlated analysis, etc., and achieve the effect of improving the measurement success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

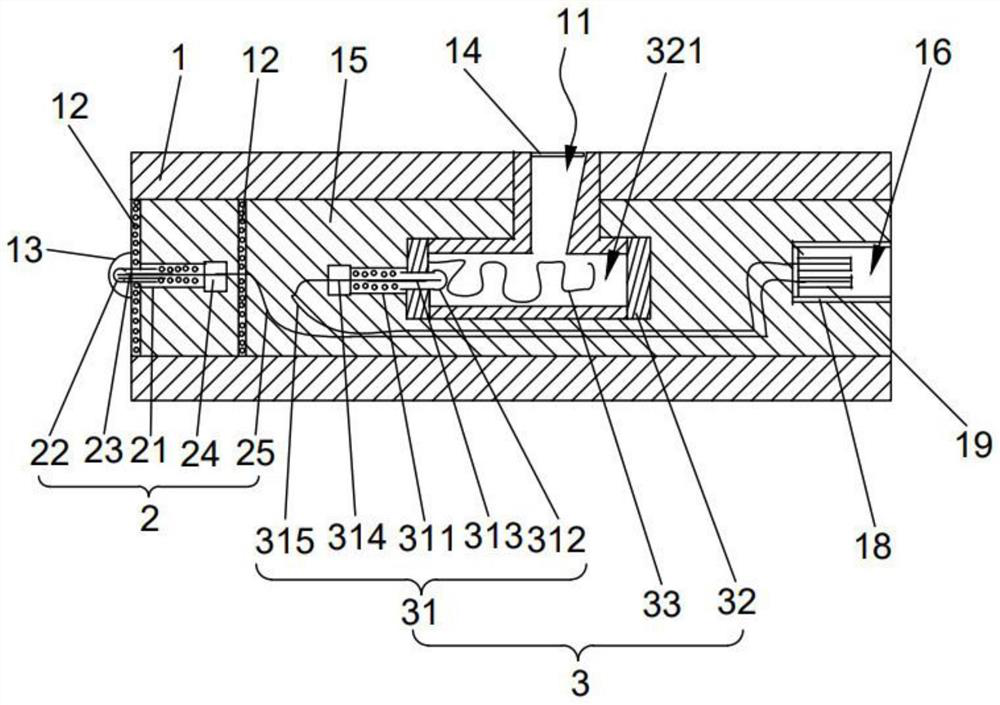

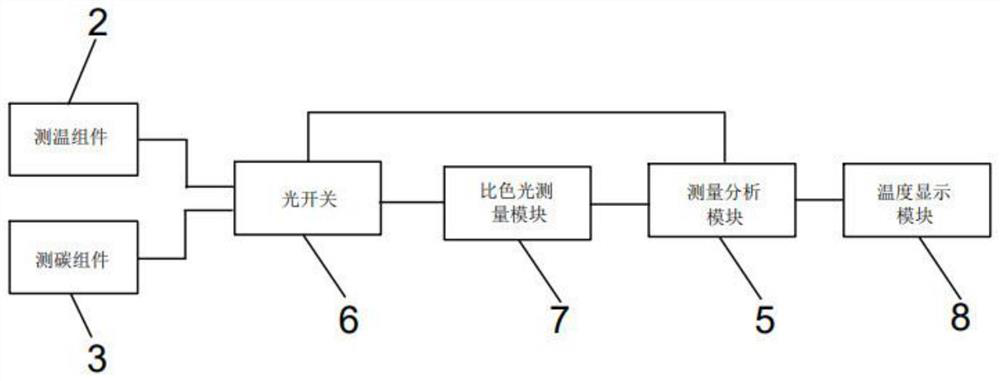

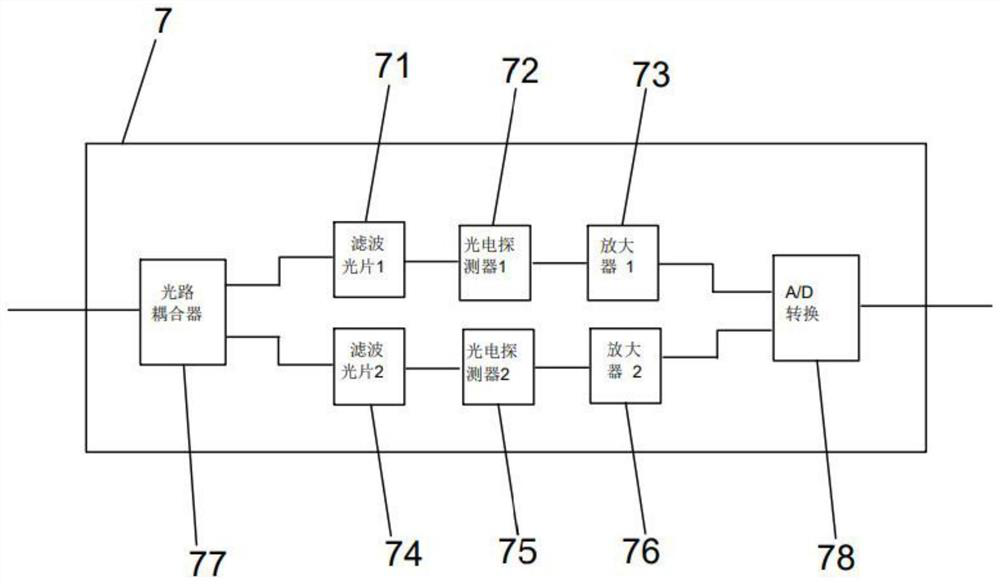

[0061] This embodiment provides a composite probe for information collection during the converter steelmaking process. Specifically, such as figure 1 As shown, the composite probe includes a probe protection tube 1, a temperature measurement component 2, a carbon measurement component 3 and a measurement analysis module ( figure 1 not shown).

[0062] Wherein, the probe protection tube 1 is used to protect the temperature measuring component 2 and the carbon measuring component 3 to prevent them from being damaged when they are inserted into the high-temperature molten steel. A sample inlet 11 communicating with the inner cavity of the probe protection tube 1 is opened. One end of the temperature measurement component 2 is packaged in the probe protection tube 1, and the other end protrudes from the nozzle of the probe protection tube 1. The end of the temperature measurement component 2 protruding from the probe protection tube 1 can measure the temperature of molten steel ...

Embodiment 2

[0093] This embodiment provides a composite probe. The difference between this embodiment and Embodiment 1 is that in this embodiment, the composite probe further includes a sampling cup; and / or a molten steel level measuring component; and / or an oxygen measuring component. That is to say, the composite probe provided in this embodiment can have five functions of temperature measurement, carbon determination, oxygen measurement, sampling, and molten steel level measurement, which greatly improves the efficiency of measurement and detection.

[0094] Optionally, the sampling cup is arranged in the probe protection tube 1, close to one end of the temperature measuring component 2, and the mouth of the sampling cup faces outward. When the composite probe enters the molten steel, the molten steel generates a positive pressure, and the molten steel enters the cold sampling cup under the action of the positive pressure, and cools and solidifies into solid steel within a few seconds. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com