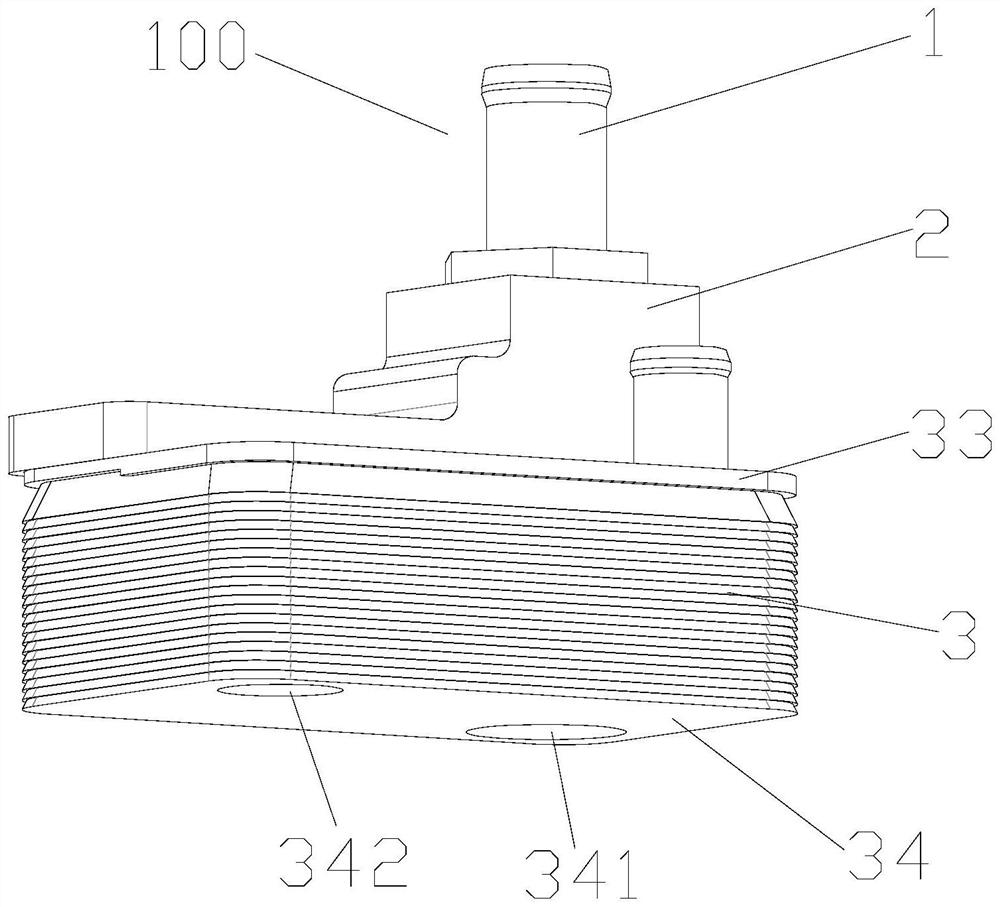

Heat exchange assembly

A technology of heat exchange components and heat exchange cores, which is applied to transmission parts, gear lubrication/cooling, belts/chains/gears, etc. It can solve problems affecting the performance of lubricating oil, fluctuations in heat exchange, etc., and achieve good control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

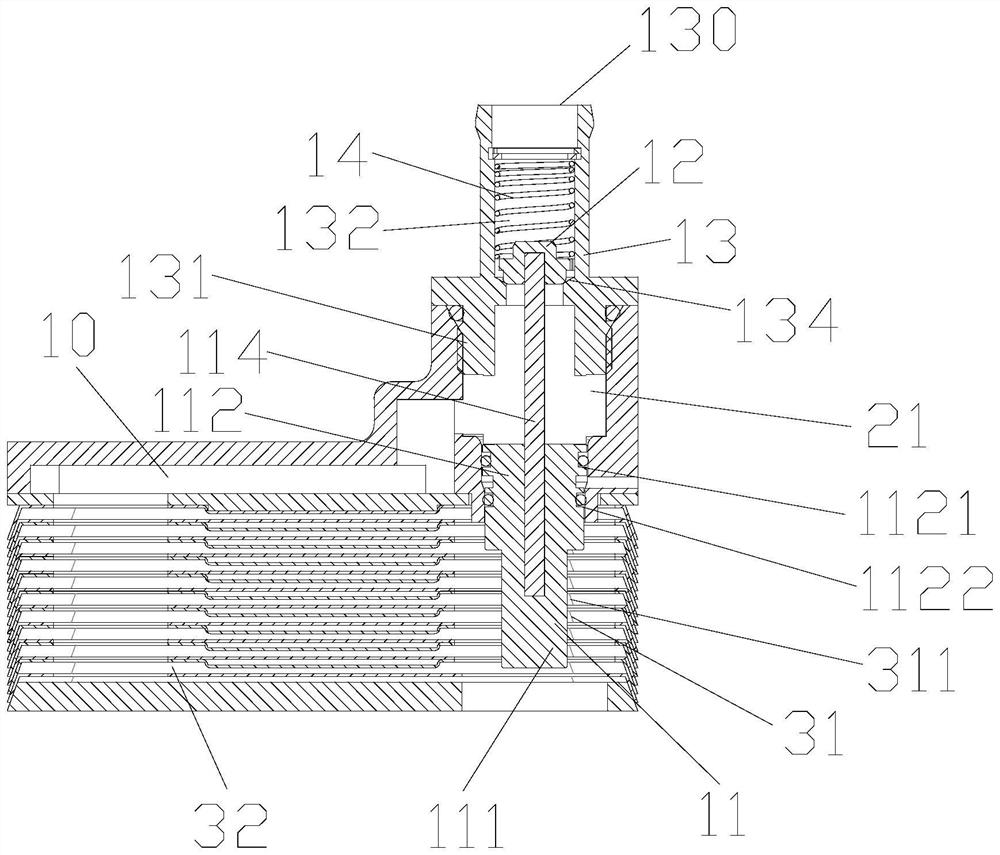

Embodiment 2

[0028] Such as Figure 8 to Figure 9 As shown, the valve body 13 includes a third connecting portion 133 , the thermally actuated portion 11 includes a third fitting portion 113 , and the third connecting portion 133 is fixedly connected or limitedly connected to the third fitting portion 113 . The valve body 13 also has a communication hole 135, which communicates with the valve port. The communication hole is closer to the thermal part than the valve port. Along the axial direction of the first hole 311, the communication hole 135 is located between the first connecting part 131 and the second connecting part. Between the parts 112, the communication hole 135 has a communication port in the outer wall of the valve body to communicate with the first communication channel.

[0029] In one implementation of this embodiment, the third connecting portion 133 is an internal thread, the internal thread 1331 is located inside the valve body 13 , and the internal thread is located be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com