Path self-changing type magnetic powder circulation drying furnace

A drying furnace and self-changing technology, applied in drying, dryer, drying room/container, etc., can solve the problems of affecting the quality of magnetic powder, low drying efficiency, uneven drying, etc., to improve drying uniformity, improve Efficiency, the effect of improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

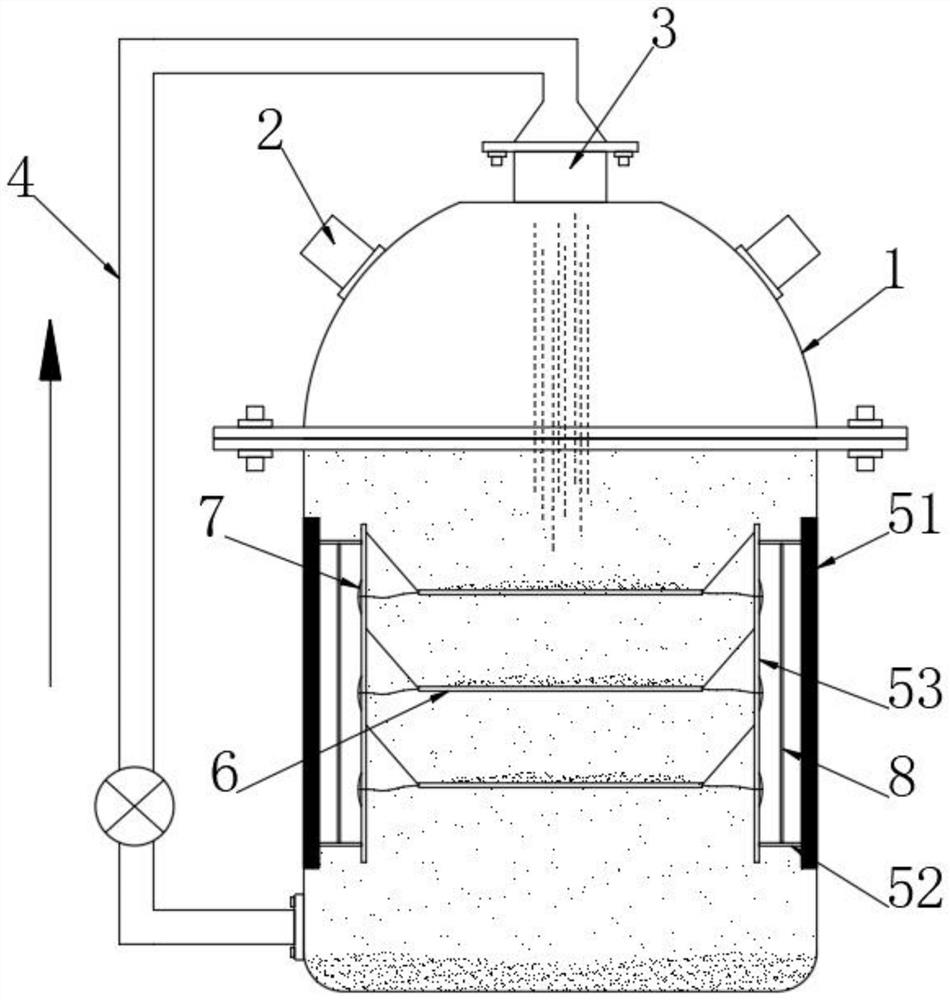

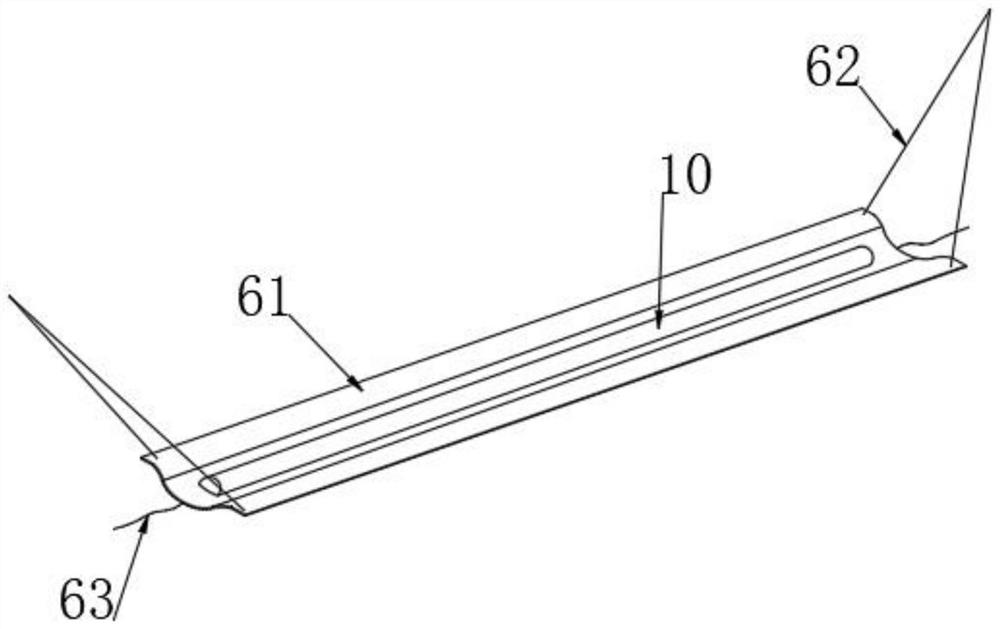

[0045] see figure 1 , a self-changing path magnetic powder circulation drying furnace, including a furnace body 1, two mutually symmetrical air holes 2 are installed on the upper end, and the two air holes 2 are respectively used for introducing hot air flow and exhaust gas, and the upper end of the furnace body 1 is fixedly connected There is a feed port 3, and a pipe 4 is connected between the outer end of the lower part of the furnace body 1 and the feed port 3, and a powder delivery pump is installed on the pipe 4, and two mutually symmetrical deflection magnetic plates are fixedly connected inside the furnace body 1. There are multiple groups of evenly distributed dispersing swing plates 6 fixedly connected between the two deflection magnetic plates.

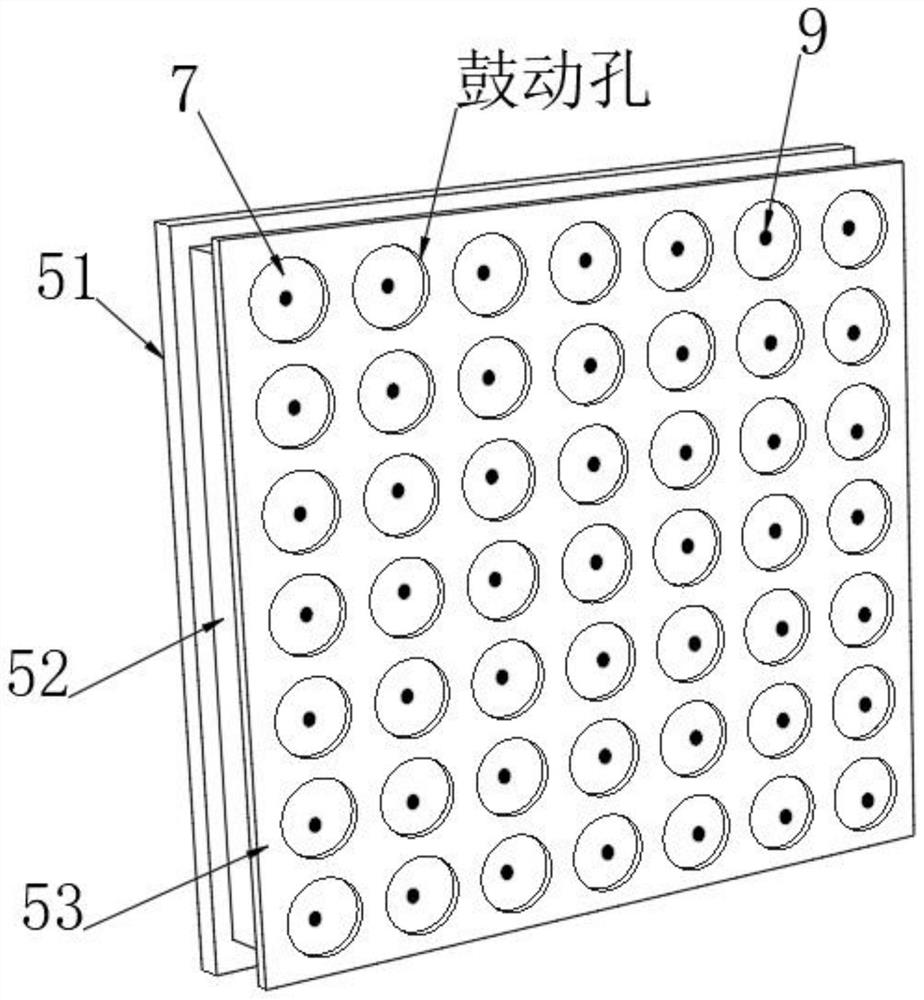

[0046] see figure 2 The deflection magnetic plate includes an electromagnetic plate 51 electrically connected to the inner wall of the furnace body 1, an outer bulge plate 53 outside the electromagnetic plate 51, and an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com