Intelligent weighing device for transmission shaft assembly

A technology of intelligent weighing and transmission shaft, which is applied in the direction of measuring devices, cooperative operation devices, and detailed information of weighing equipment, etc., which can solve the problems of increasing labor time, inaccurate weighing results, and unbalanced pressure on the weighing platform, etc. problem, to achieve the effect of saving manual calculation steps, stable and accurate data, and accurate weighing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

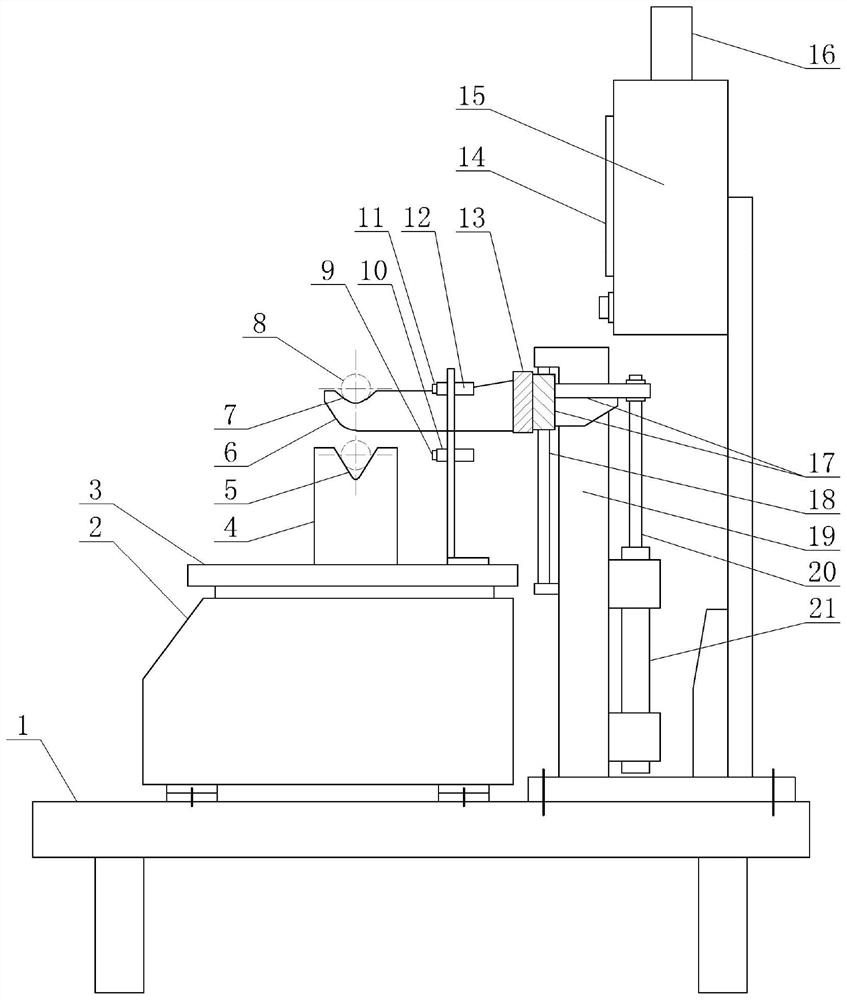

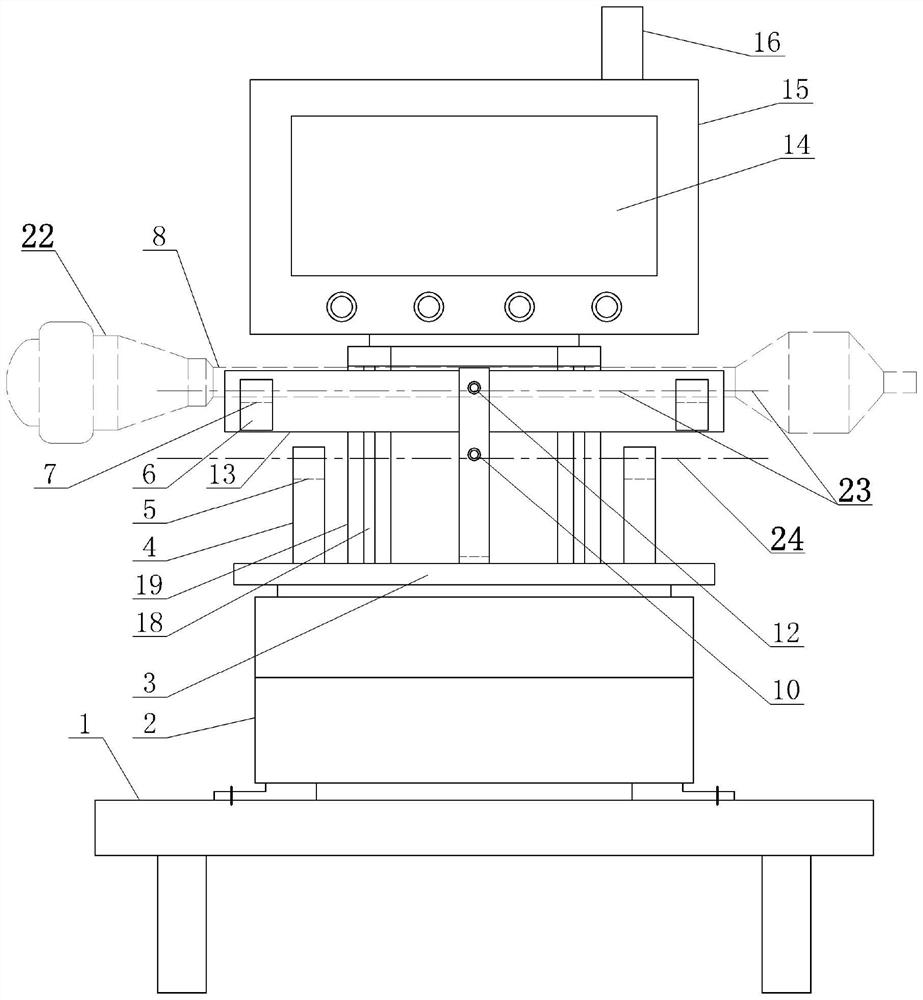

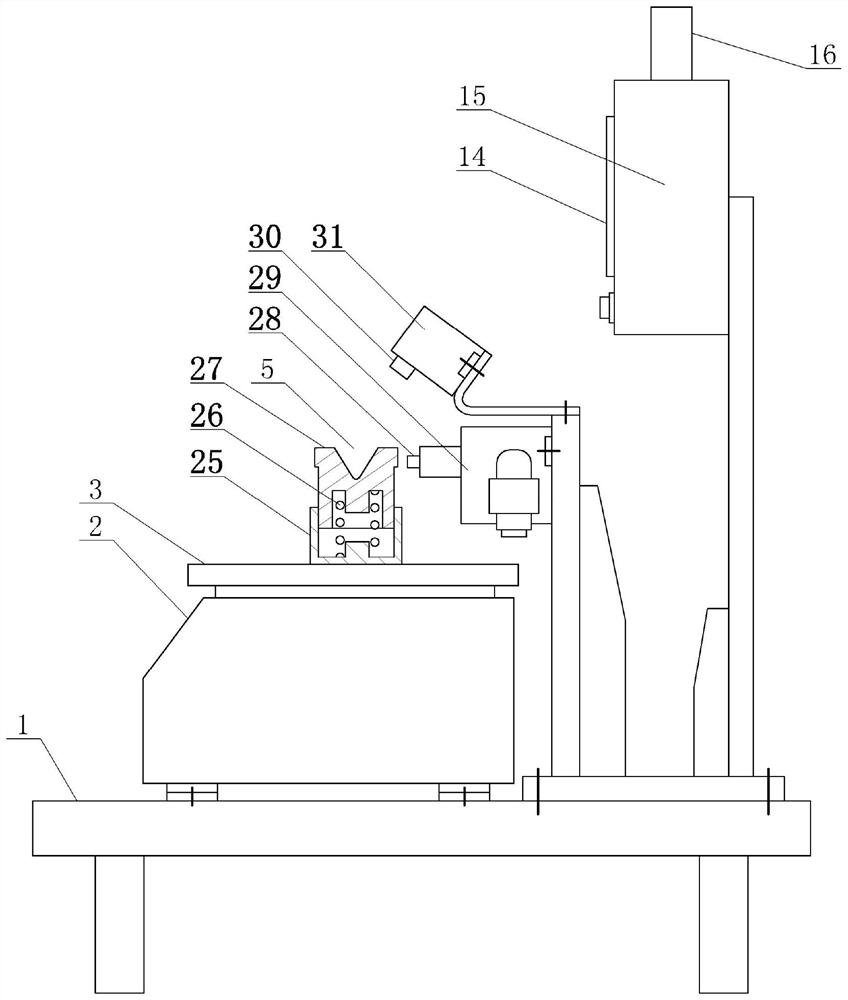

[0026] Drive shaft assembly intelligent weighing device, such as figure 1 , figure 2 and Figure 4 Shown, it has frame 1, is provided with electronic scale 2, alarm 16, first workpiece sensor 10 and controller 15 on the frame, wherein, the weighing platform 3 of electronic scale is provided with two shafts arranged symmetrically. Rod bracket 4, the lower ends of the two shaft brackets are fixedly connected to the weighing platform, and the upper ends of the two shaft brackets are respectively provided with V-shaped or U-shaped first gaps 5, and the two first gaps are arranged oppositely; the first workpiece sensor The detection end 9 is opposite to the space between the two first gaps; the signal output end of the electronic weighing instrument and the signal output end of the first workpiece sensor are respectively connected with the signal input end of the controller through a signal line, and the signal output end of the controller The terminal is connected with the signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com