Micro-assembly material intelligent warehousing system and method

A technology of intelligent warehousing and micro-assembly, applied in logistics, collaborative operation devices, data processing applications, etc., can solve the problems of material management chaos and low efficiency, and achieve the effect of solving material management chaos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The design solutions in the examples of the present invention will be described in detail below in conjunction with the accompanying drawings. Obviously, the examples are only a part of the present invention and do not represent all examples. Other examples on the premise that the inventors in the field have not made obvious creative work all belong to the protection scope of the present invention.

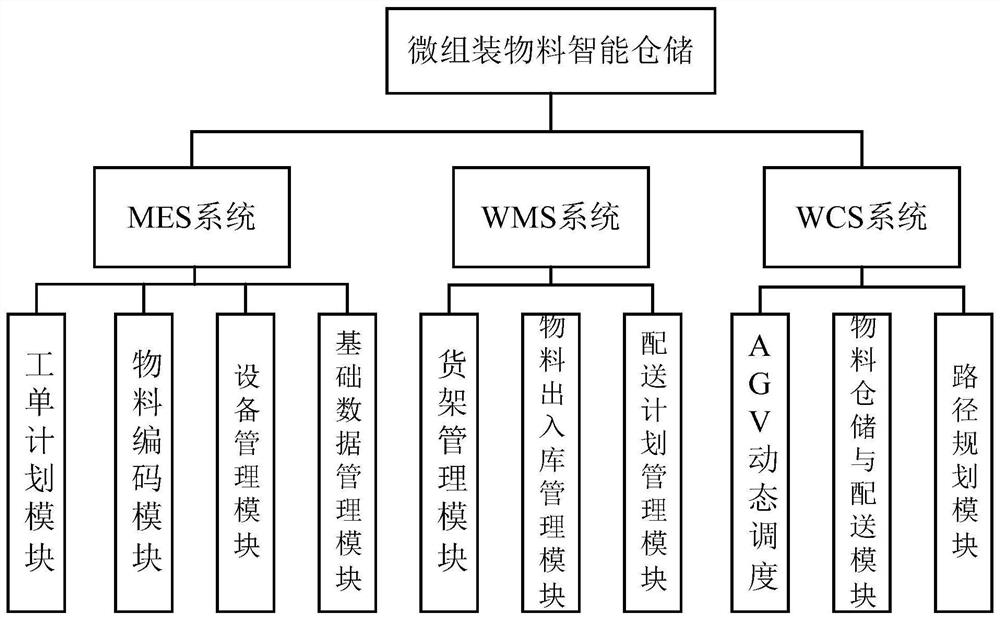

[0024] figure 1 It is the basic structural diagram of the present invention. There are 3 systems.

[0025] (1) MES system: including work order planning, material coding, equipment management, and basic data management modules. When the first piece is produced, technical personnel need to maintain information such as materials, process flow, shifts, groups, etc., form a production work order plan, review and issue work orders. Subsequent mass production only needs to formulate a production plan and release it.

[0026] (2) WMS system: including shelf management, materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com