Flexible welding production line and clamp welding and overhauling station switching method

A welding production line and fixture technology, applied in welding/cutting auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of occupying manpower time, manual management of welding fixtures, and welding fixtures occupying a large production site, etc., to achieve accurate positioning. The effect of installation, convenient equipment maintenance, and efficient management of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

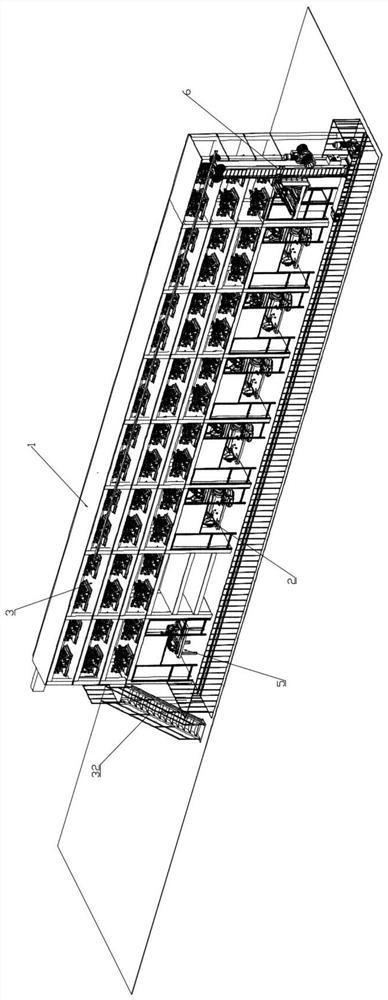

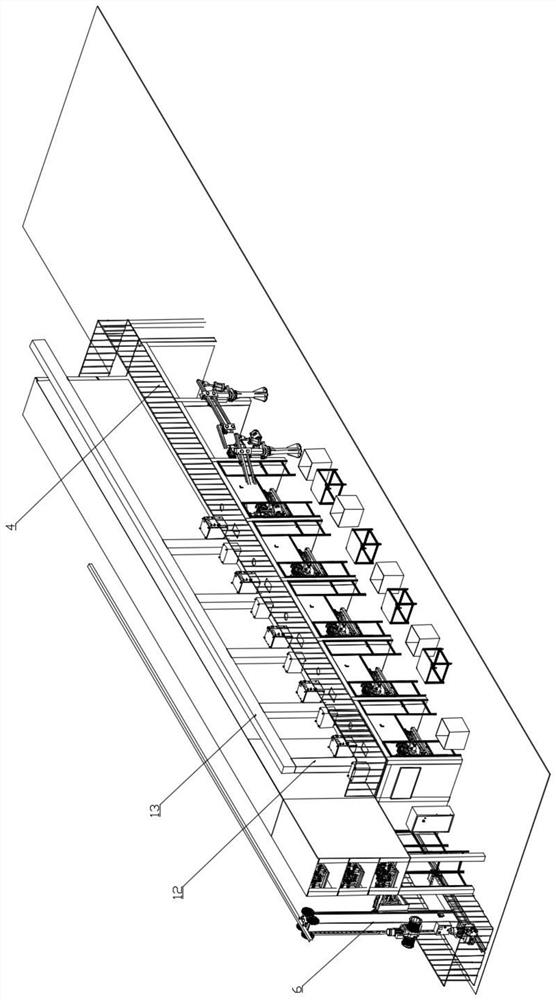

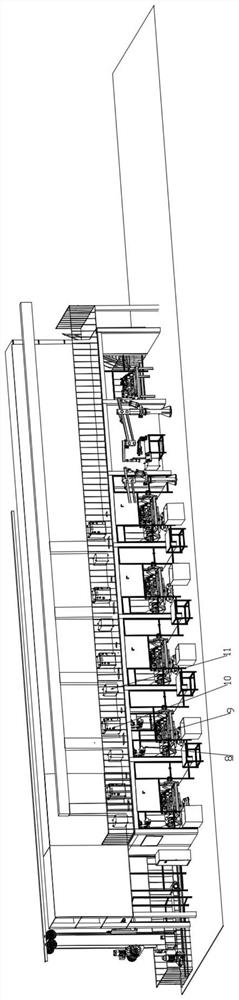

[0052] Example: such as Figure 1-12 As shown, a flexible welding production line includes a three-dimensional multi-layer main steel structure. The main steel structure 1 is a steel structure building assembled by section steel and steel pipe through screw connection or welding. It plans flexible automatic welding unit and tooling maintenance unit on the bottom layer, and plans tooling automatic storage system, centralized smoke exhaust system, equipment maintenance channel, etc. on the upper layer.

[0053] Specifically, the first layer of the main steel structure is provided with a plurality of automatic welding units 2 and tooling maintenance units 5 . The upper layer of the main structure is provided with a plurality of tooling storage units 3 and equipment maintenance passages 4, and a ladder 32 is provided at one end of the maintenance equipment passages for ease of going up and down, and guardrails are provided on the edges of the maintenance passages and ladders to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com