Shaft seal device suitable for stirring shaft of ultrahigh pressure reaction kettle

A technology of stirring shaft and reaction kettle, which is applied to pressure vessels used in chemical processes, chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, etc. Use efficiency and other issues to achieve the effect of improving work efficiency, ensuring stability, and strengthening sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

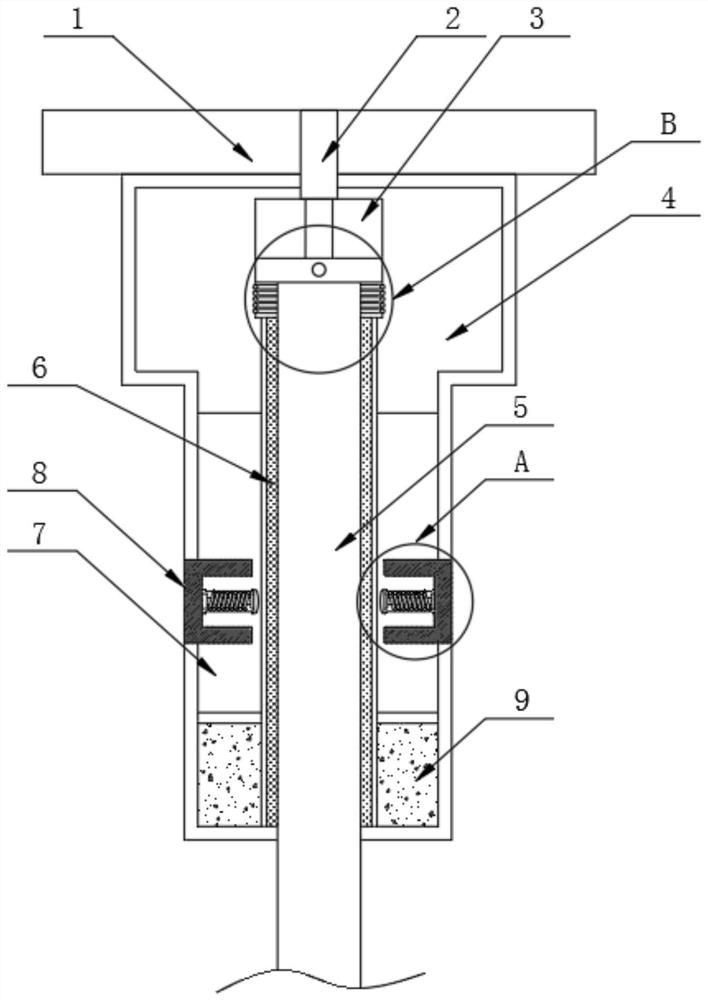

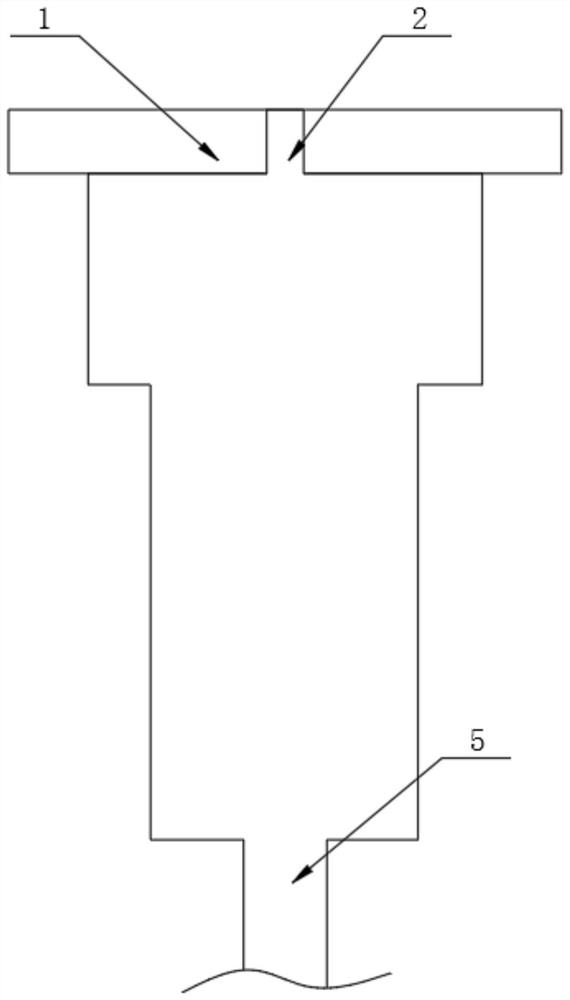

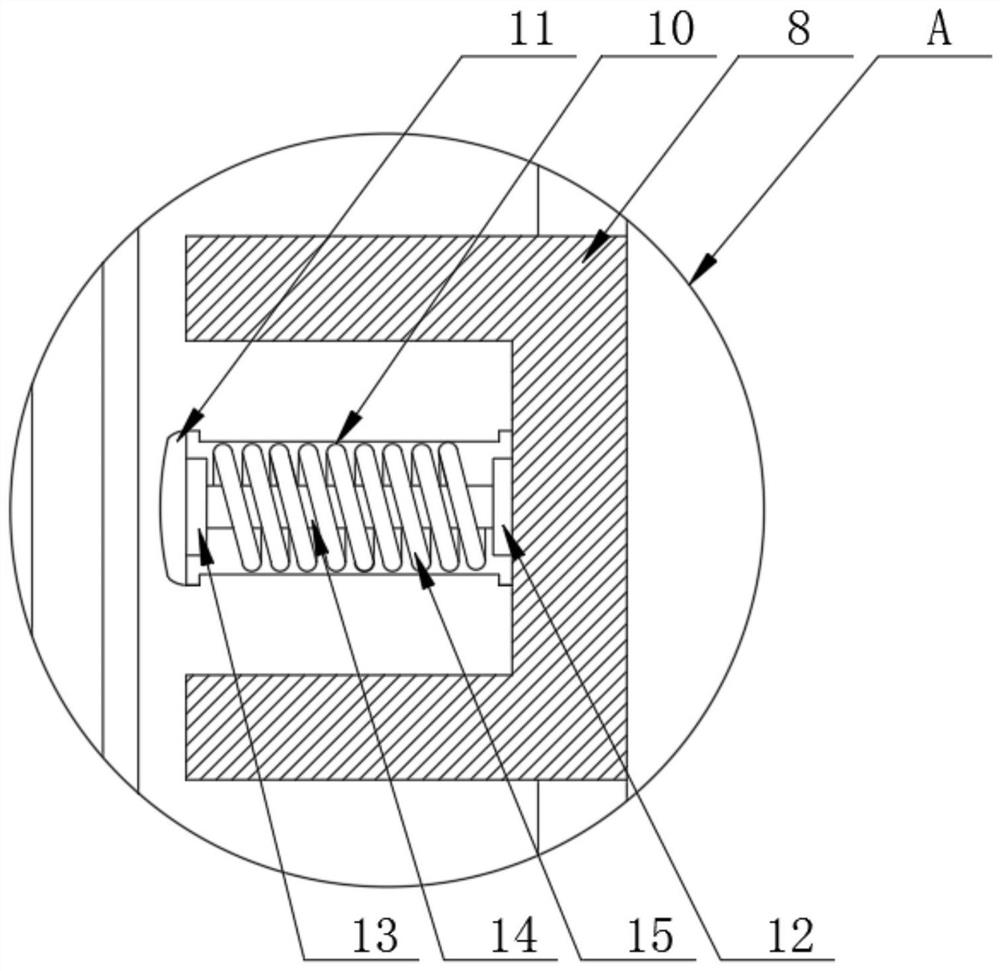

[0022] as attached figure 1 To attach Figure 5 The embodiment of the present invention provides a shaft sealing device suitable for the stirring shaft of an ultra-high pressure reactor, including a motor base 1, a motor shaft 2 and a coupling 3, and a sealing sleeve 4 is fixedly installed on the bottom end of the motor base 1, The bottom end of the sealing sleeve 4 communicates with the kettle body 7, the bottom end of the motor shaft 2 is fixedly connected with a drive shaft 18, the bottom end of the drive shaft 18 is fixedly connected with a bottom plate 19, and the bottom end of the bottom plate 19 A stirring shaft 5 is fixedly connected, the surfaces of the stirring shaft 5 are attached to each other with sealing rings 6, the inner wall of the kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com