Insole integral forming filling device and forming process thereof

A molding device and insole technology, applied in the field of insoles, can solve the problems of poor product consistency, high labor intensity, poor paste stability, etc., saving labor costs and material costs, obvious bulging effect, and strong promotion. effect of meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical scheme and advantages of the invention more clear, the invention is further described in detail below in combination with the accompanying drawings and embodiments.

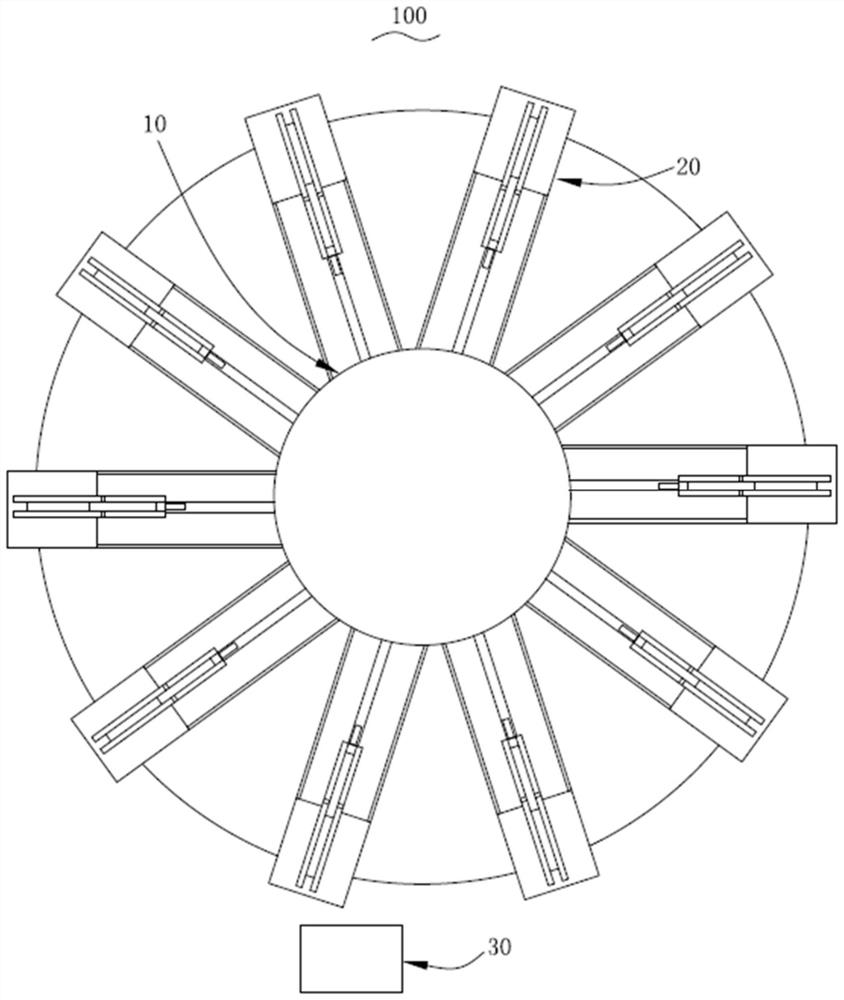

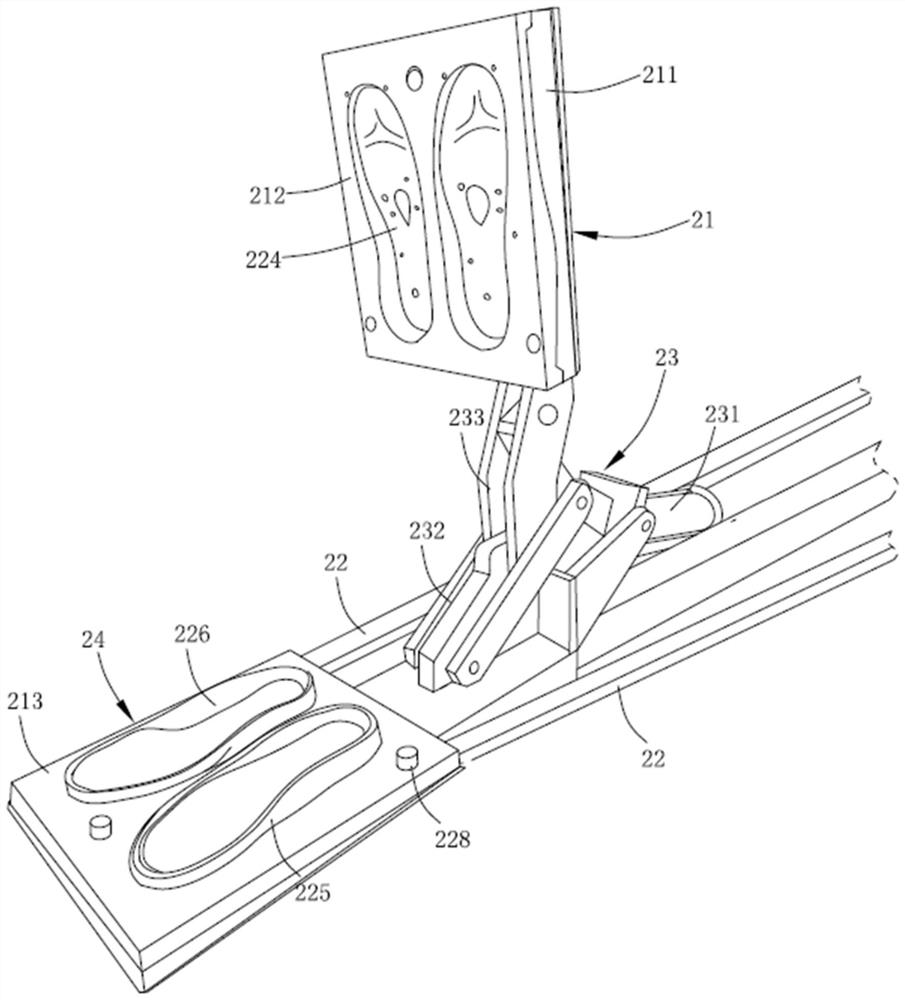

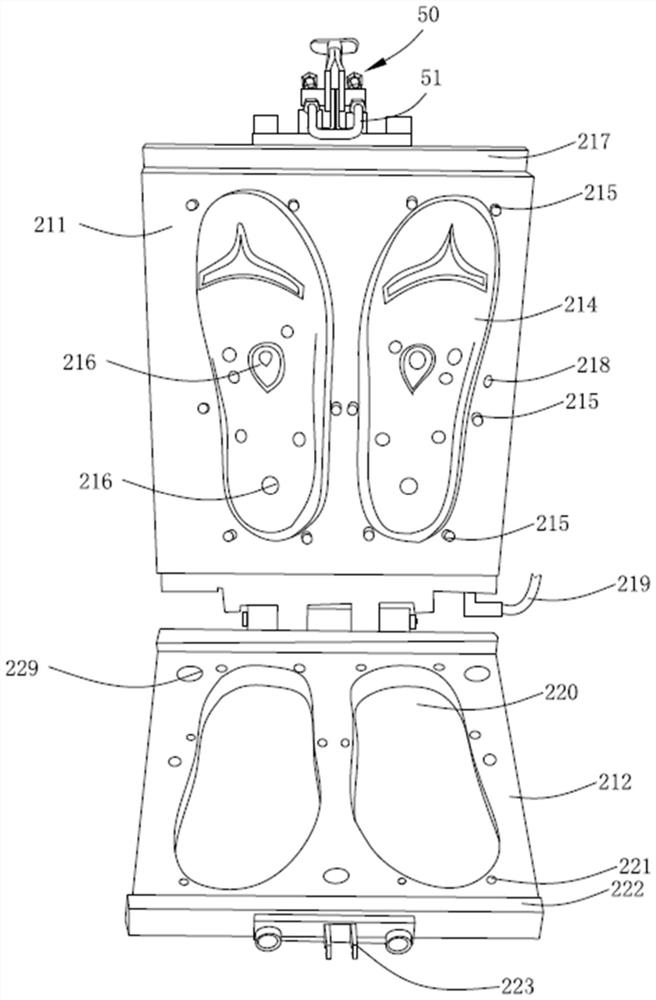

[0035] as Figures 1 to 3 As shown in the figure, the invention provides an integrated molding pouring device for insoles, which is used for molding insoles or other products of the same type. The specific production products are not limited here. The insole integrated molding pouring device comprises a central rotating part 10, a plurality of molding devices 20 and a beating device 30. The inner ends of the molding devices 20 are installed on the central rotating part 10 and can rotate around the central rotating part 10. The beating device 30 is arranged on the outside of the molding device 20 to inject molding materials into the molding device 20. In this embodiment, the number of the beating device 30 is one, and several forming devices 20 rotate to the beating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com