On-line compression molding die and molding process for composite scraper

A molding and scraping technology, applied in the direction of household appliances, other household appliances, household components, etc., can solve the problem of less than expected service life, tensile strength, wear resistance, flame retardant performance, antistatic performance discount, chain breakage and other problems to achieve the effect of improving service life, reducing production cost and reducing transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

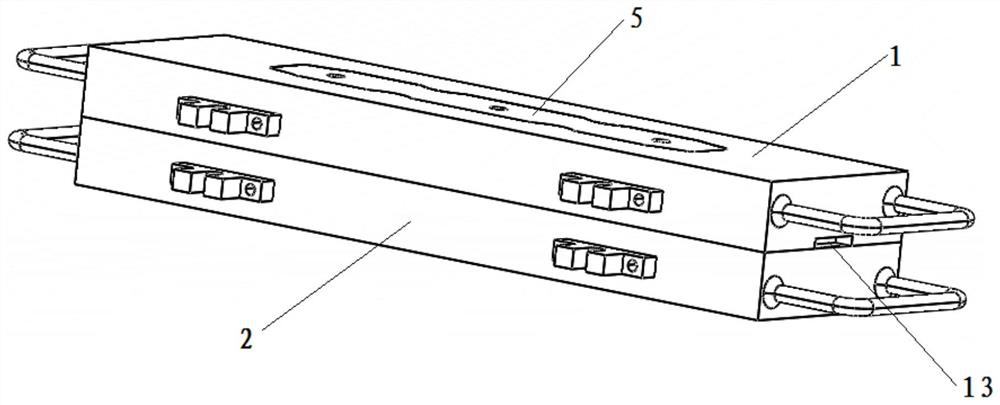

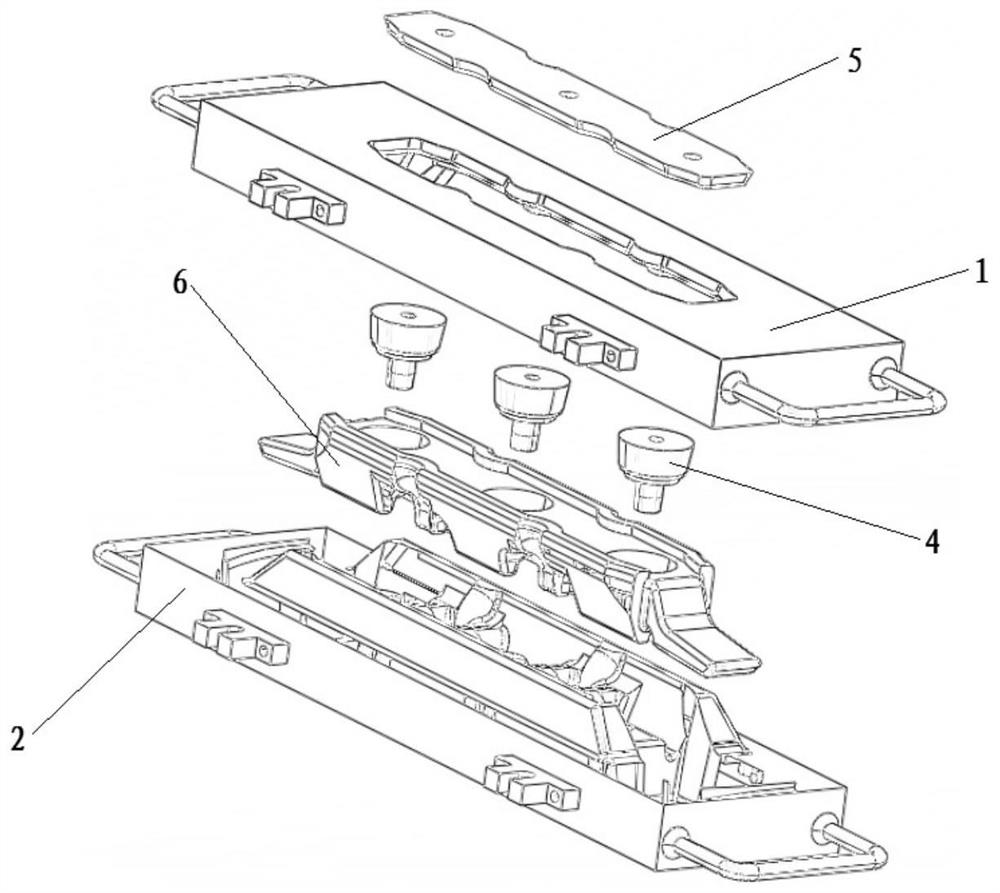

[0060] Such as Figure 2-11 As shown, the present invention provides a composite scraper online molding die, including an upper mold 1 and a lower mold 2, the upper mold 1 includes a main cavity 11 and an end cavity 12 communicating with the left and right ends of the main cavity 11 , the lower mold 2 includes a main groove 21 and end grooves 22 located at the left and right ends of the main groove 21. There is a vertical joint 23 between the main groove 21 and the end groove 22, and the front and rear sides of the main groove 21 are The side distribution is provided with an upwardly protruding groove guard frame 24, the main cavity 11 includes a first stepped cavity 111 that is compatible with the groove guard frame 24, and the upper mold 1 is locked with the lower mold 2 After the connection, the first stepped cavity 111 covers the groove guard frame 24 and forms the molding cavity 3 .

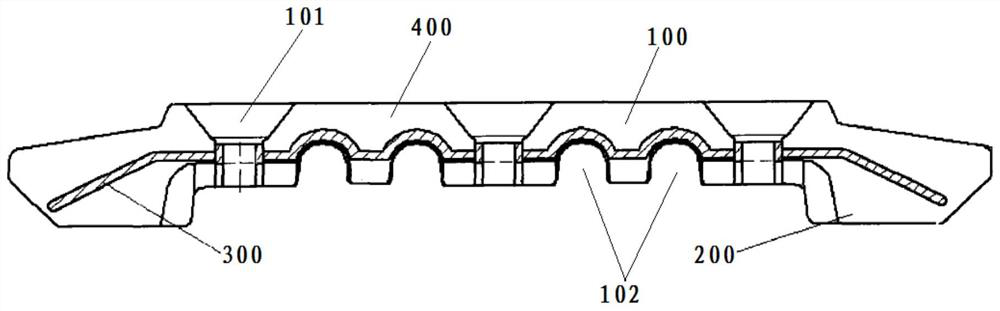

[0061] Specifically, such as figure 1 As shown, when the composite scraper operates in...

Embodiment 2

[0092] The present invention also provides a composite scraper online molding process, which uses a composite scraper online molding mold, which includes the following steps:

[0093] S1: Start the temperature-controlled compression molding machine, remove the upper mold 1, and take an appropriate amount of blank and place it in the end cavity 12;

[0094] S2: Move the preheated special core insert 6 into the lower mold 2, and position the positioning plug 4 in advance;

[0095] S3: Take an appropriate amount of blank again and place it in the weight-reducing groove 611 of the special core insert 6;

[0096] S4: Move the upper mold 1 to the top of the lower mold 2, start the slider of the temperature control molding machine to move down and quickly close the mold;

[0097] S5: After one mold clamping and finalizing, start the slider of the temperature control molding machine to go up, and complete an open exhaust;

[0098] S6: Move the upper mold 1 to the top of the lower mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com