Movement mechanism and mechanical equipment

A technology of motion mechanism and rotating parts, which is applied in the field of mechanical motion, can solve problems such as low work efficiency, and achieve the effect of speeding up and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

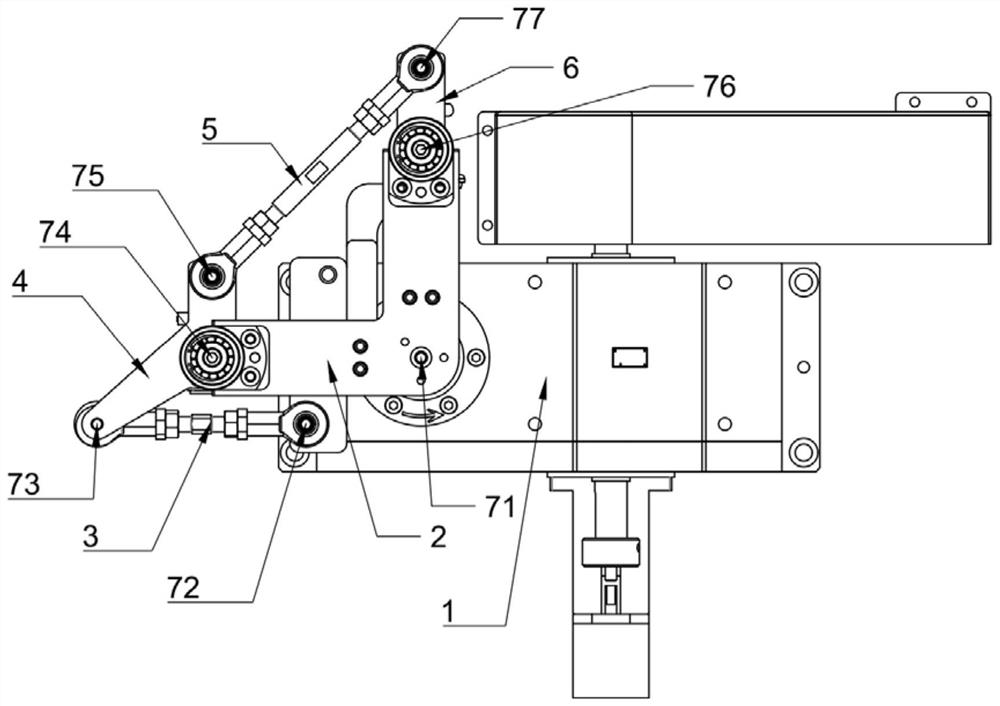

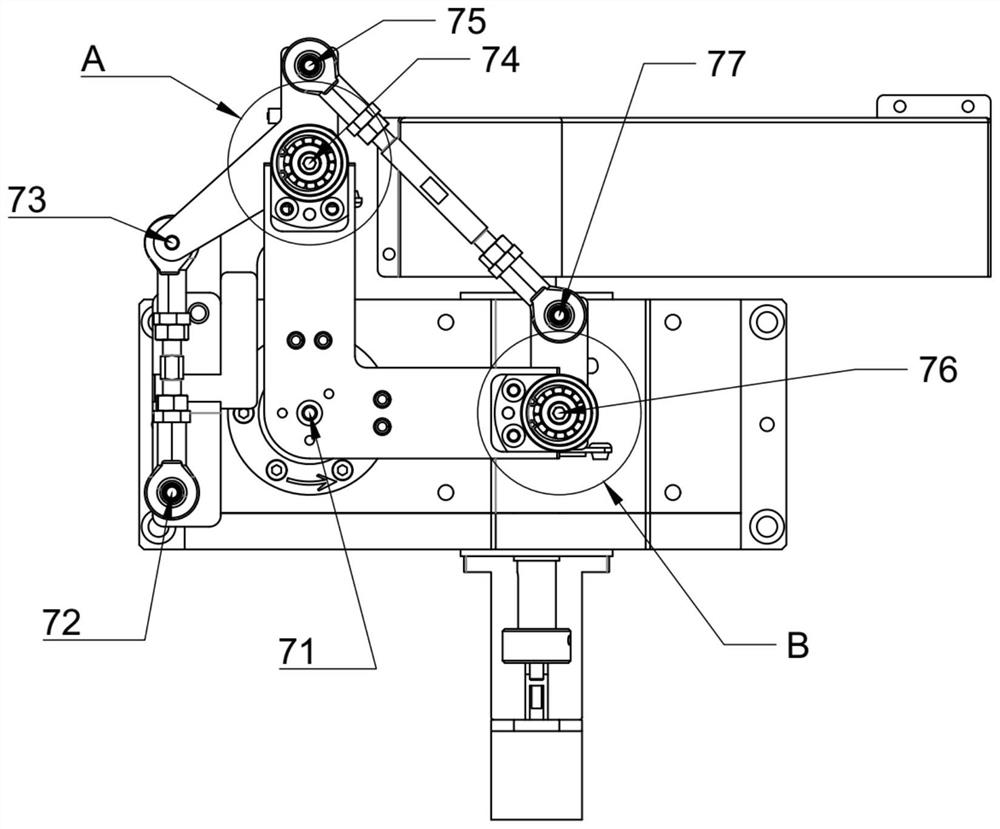

[0052] refer to figure 1 , figure 2 , a motion mechanism, the motion mechanism includes a base 1, a first rotating member 2, a first connecting rod 3, a second rotating member 4, a second connecting rod 5, a third rotating member 6 and a transmission member.

[0053] The base 1, the base 1 is provided with an accommodating cavity, the transmission part is placed in the accommodating cavity and is used to control the lifting and rotating movement of the first rotating part 2, and the transmission part is located in the base 1 to protect the transmission part;

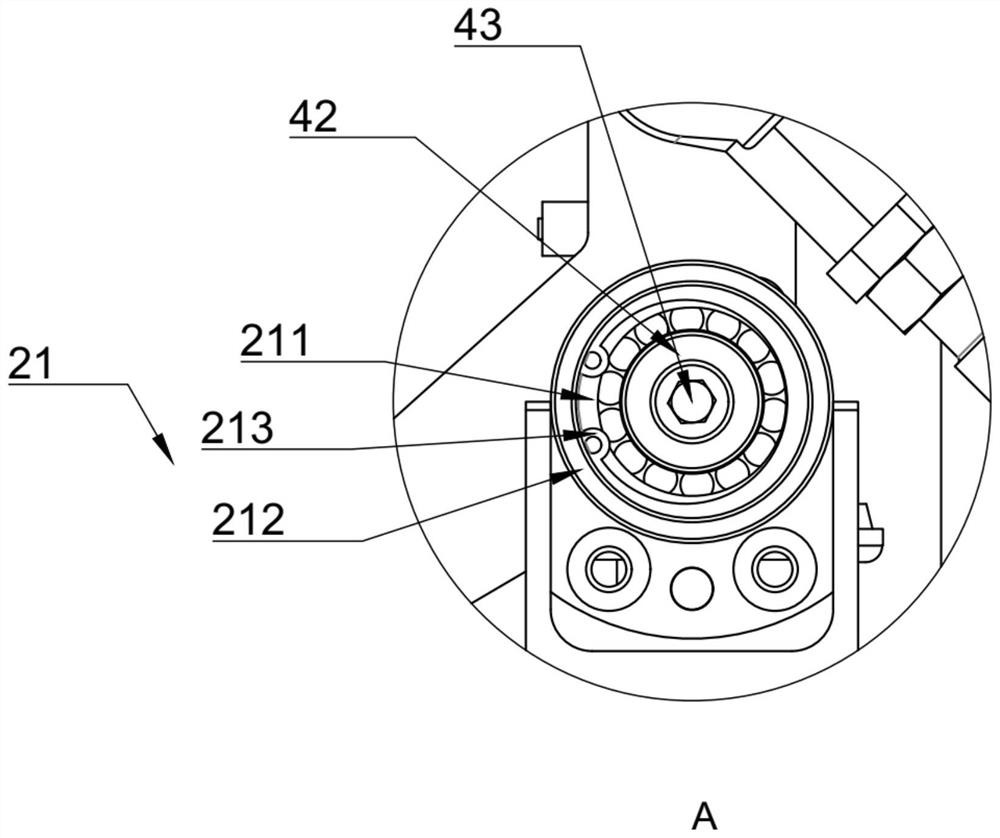

[0054] The first rotating member 2 slides relative to the base 1 along the direction of the first axis 71, rotates relative to the base 1 around the first axis 71, is connected to the second rotating member 4 around the fourth axis 74, and rotates around the sixth axis. 76 is rotatably connected to the third rotating member 6;

[0055] Specifically, the first rotating part 2 is provided with a lifting rotating shaft, ...

Embodiment 2

[0070] A mechanical device, including a feed line, a detection line, a discharge line and the above-mentioned motion mechanism, the feed line is provided with a first station, the detection line is provided with a second station, and the discharge line is provided with a third station, And both the first working station and the second working station are equipped with manipulators for relay transfer, wherein the position of the first station corresponds to the first position, the position of the second station corresponds to the second position, and the third The position of the workstation corresponds to the third position. In this embodiment, the mechanical equipment is used for relay transfer, because it is understood that, according to the usage scenario, the first station, the second station and the third station may also be processing stations, testing stations, etc.

[0071] The relay is a cuboid, if it is transported along the wide side, it is easy to fall down, so the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com