Actuating device for clutch device, clutch device having such actuating device, and method for producing such actuating device

A technology of clutches and double clutches, applied in fluid pressure actuators, clutches, fluid-driven clutches, etc., can solve problems such as laborious manufacturing and achieve reliable positioning and centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

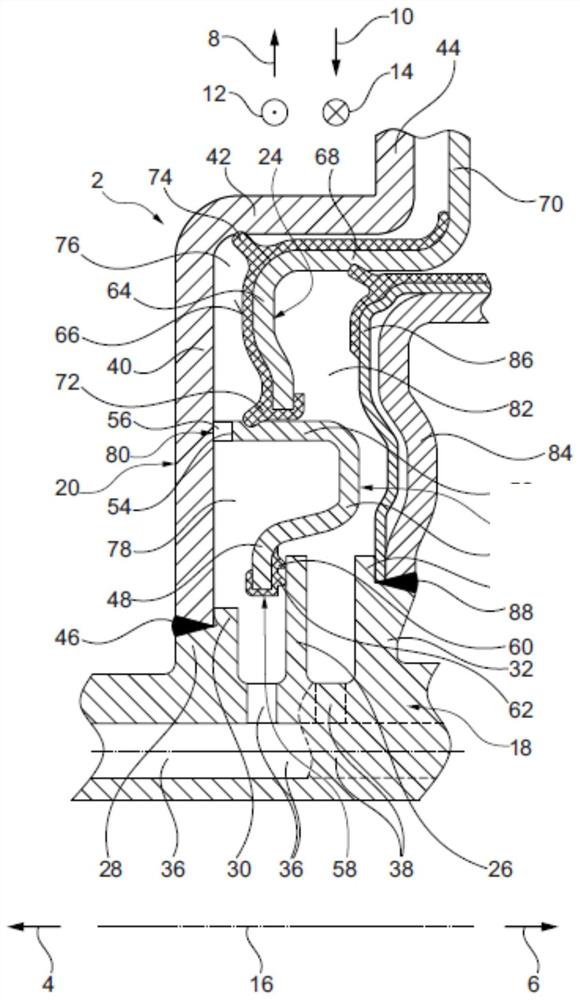

[0030] figure 1 A hydraulic actuation device 2 is shown for use in a clutch arrangement of a drive train of a motor vehicle. exist figure 1 , the mutually opposite axial directions 4, 6, the mutually opposite radial directions 8, 10 and the mutually opposite circumferential directions 12, 14 of the actuating device 2 or the clutch arrangement are indicated by means of corresponding arrows, wherein the actuating device 2 Or the clutch device is rotatable in the circumferential direction 12 , 14 about a rotational axis 16 extending in the axial direction 4 , 6 . The two axial directions 4 , 6 are also referred to below as the first axial direction 4 and the second axial direction 6 .

[0031] The actuating device 2 essentially consists of a hub 18 , a first housing part 20 , a second housing part 22 and an actuating piston 24 . The hub 18 is substantially tubular and extends in the axial direction 4 , 6 . In this case, the hub 18 is preferably used as an optionally input-sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com