Friction disc type continuously variable transmission and continuously variable speed regulation method

A continuously variable transmission, friction disc technology, applied in the direction of friction transmission, transmission, components with teeth, etc., can solve the problem of reducing transmission efficiency, and achieve the effect of improving efficiency, reducing the number of transmissions, and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

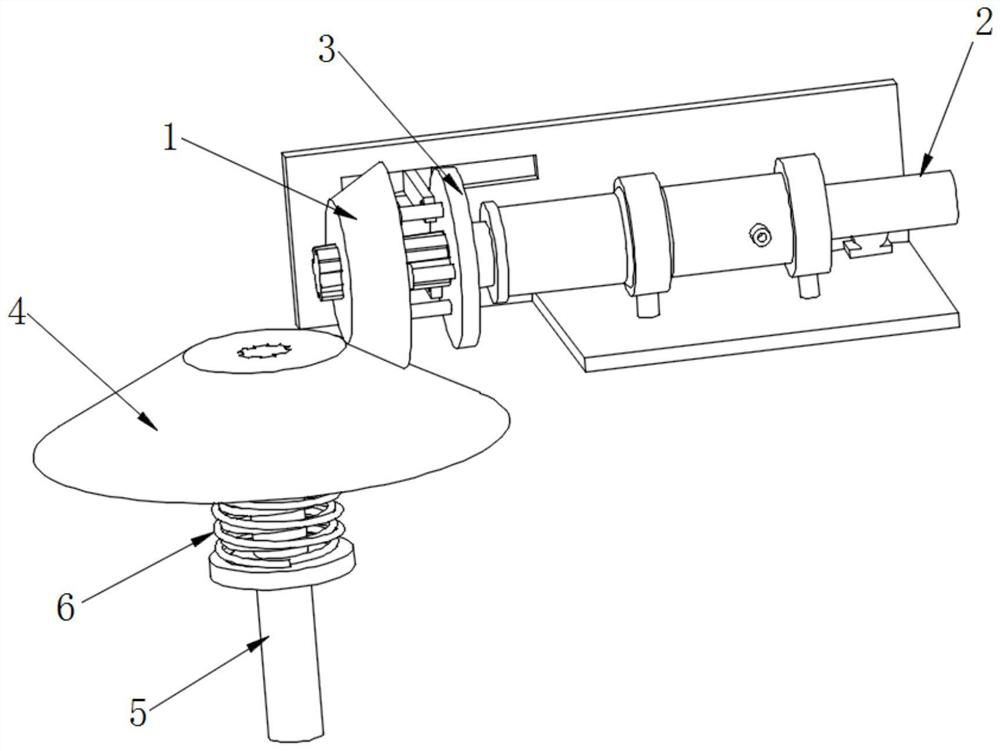

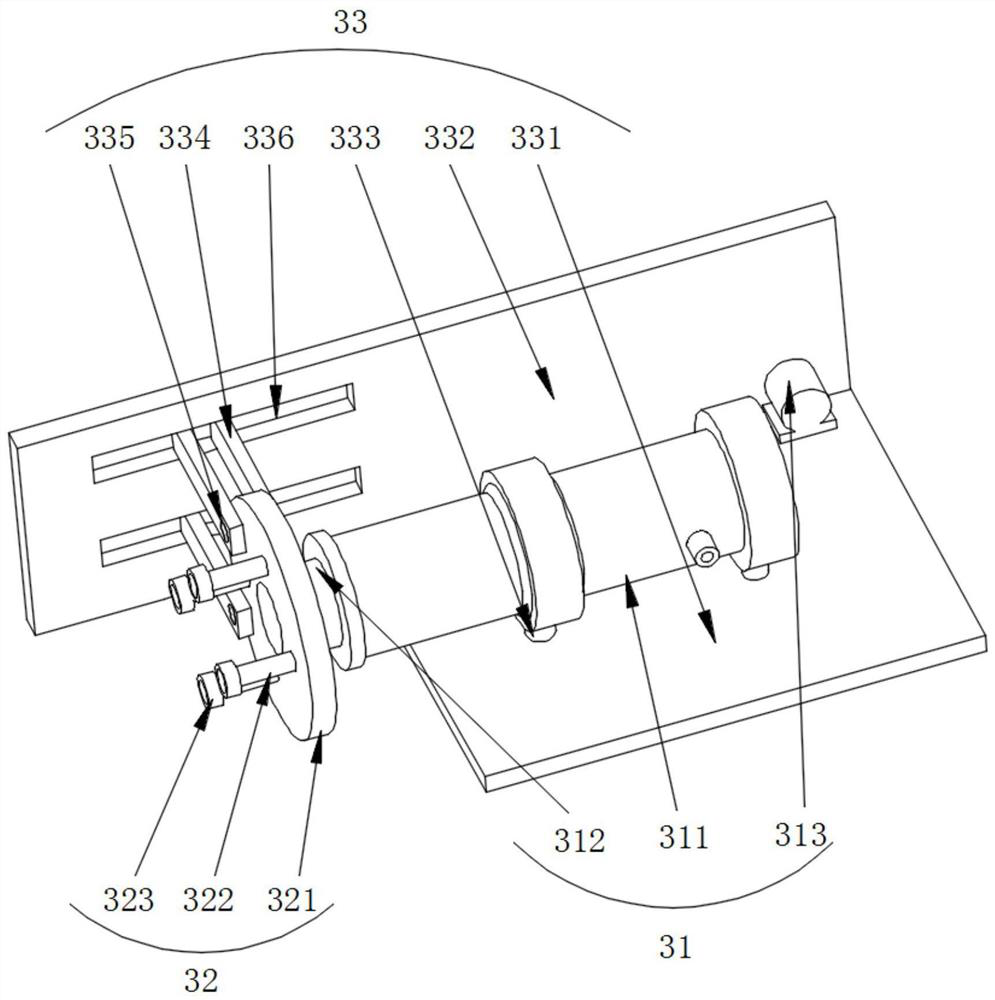

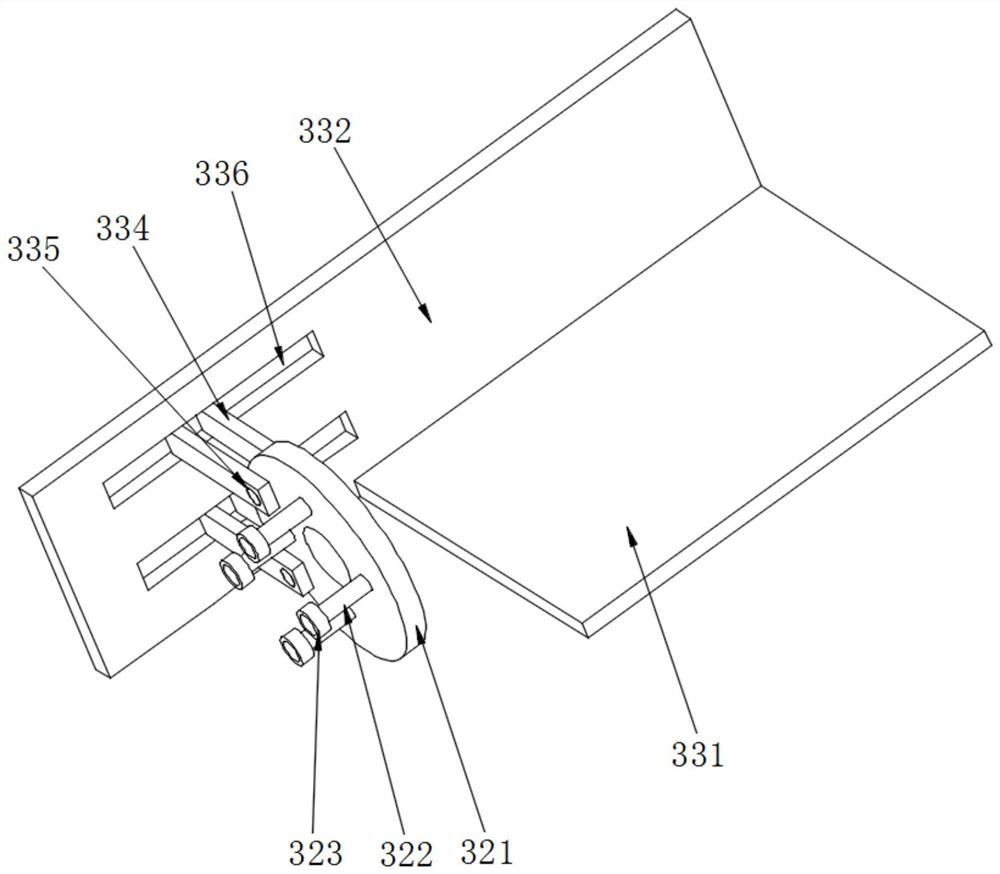

[0047] This embodiment provides a friction disc continuously variable transmission, which includes a first transmission element, a second transmission element and a push assembly 3 . refer to figure 1As shown, the first transmission element includes a first transmission disc 1 and a first transmission shaft 2, the first transmission disc 1 is a conical truncated circular structure, which has a conical annular slope; The end of a transmission shaft 2 is a spline structure, which is keyed to the first transmission disc 1, so that the first transmission shaft 2 can drive the first transmission disc 1 to rotate, and the first transmission disc 1 can rotate along the first transmission disc 1. Shaft 2 slides in the axial direction. The second transmission element includes a second transmission disc 4, a second transmission shaft 5 and a spring assembly 6; the second transmission disc 4 is also a conical truncated cone structure, which also has a conical annular slope The end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com