Test method for thermal deformation of lap joint of waterproof coiled materials

A waterproof membrane and test method technology, applied in the direction of material thermal analysis, analysis of materials, suspension and porous material analysis, etc., can solve the problem of not reflecting the thermal deformation of the overlapping edge, and can not directly reflect the waterproof membrane The impact of structure etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

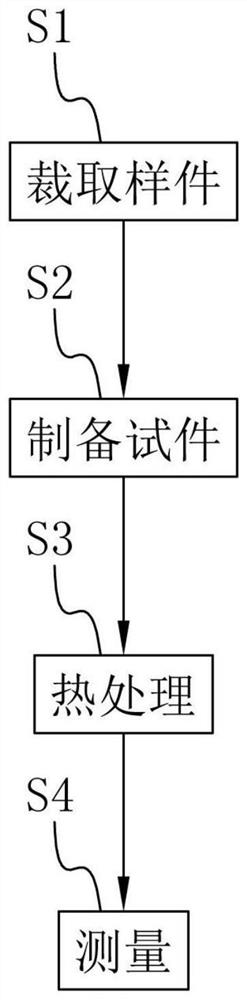

[0054] refer to Figure 1 to Figure 4 , a test method for thermal deformation of overlapping joints of waterproof membranes, comprising the following steps:

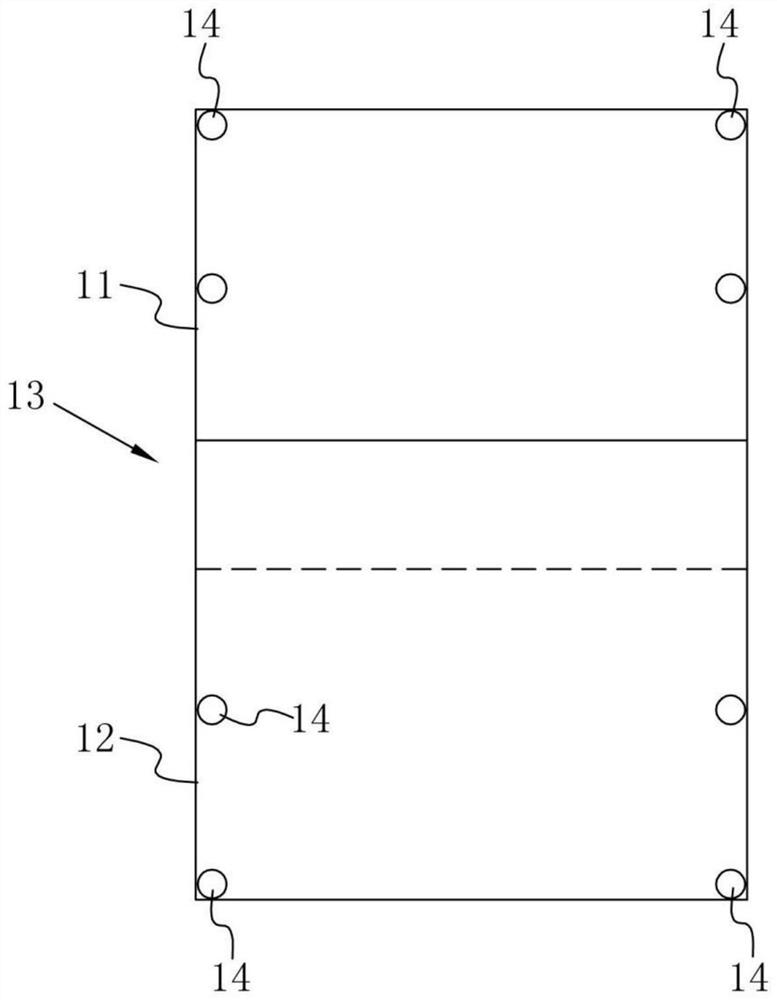

[0055] S1. Cutting samples: There is an adhesive layer on one side of the coil, and the sample 11 of the main part of the coil and the sample 12 of the lap are cut. The sample 11 of the main part and the sample 12 of the lap are cut to two different pieces. The length of the main part sample 11 and the lap joint sample 12 is 300mm, and the width of the main body sample 11 and the lap joint sample 12 is 250mm.

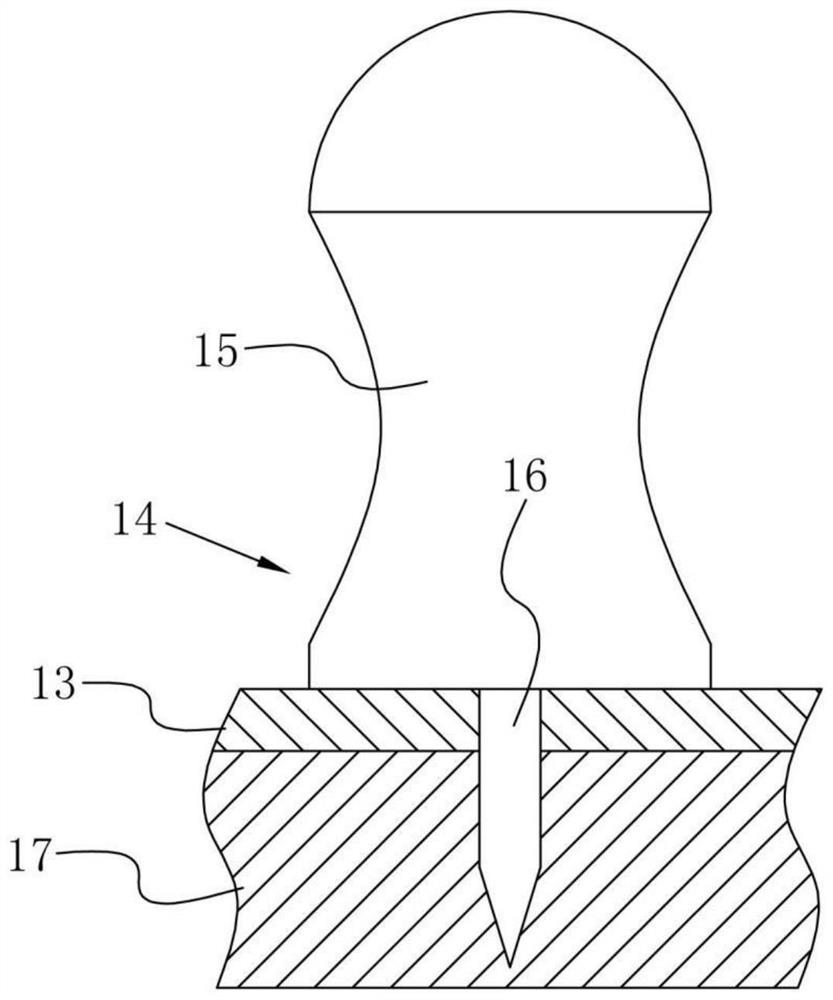

[0056] S2. Preparation of test piece: Bond the self-adhesive surface of the main part sample 11 and the lap joint sample 12. The width of the bonding position of the main part sample 11 and the lap joint sample 12 is 70 mm. After the self-adhesive surface of the piece 11 and the lap joint sample 12 is bonded, use a 2kg pressure roller to roll three times to obtain the test piece 13. The test piece 13 is rectangul...

Embodiment 2

[0076] refer to Figure 5 , a test method for thermal deformation of overlapping joints of waterproof membranes, comprising the following steps:

[0077] S1. Cutting samples: There is an adhesive layer on one side of the coil, and the samples of the main part of the coil and the samples of the lap are cut. The samples of the main part and the samples of the lap are cut into two different coils. The length of the main part sample and the lap joint sample is both 300mm, and the width of the main part sample and the lap joint sample is both 250mm.

[0078] S2. Preparation of test piece: Bond the self-adhesive surface of the main part sample and the lap joint sample. The width of the bonding position of the main part sample and the lap joint sample is 70 mm. The main part sample and the lap joint After the self-adhesive surface of the sample is bonded, use a 2kg pressure roller to roll 3 times to obtain the test piece 13. The test piece 13 is rectangular as a whole, and the test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com