Method and system for analyzing production induced stress before shale gas reservoir refracturing

A technology of repeated fracturing and induced stress, applied in special data processing applications, instruments, design optimization/simulation, etc., can solve the problem of unsuitable natural fracture development and low-porosity shale gas reservoirs, oil and gas without considering complex fracture distribution and multi-scale flow mechanism to achieve the effect of ensuring accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

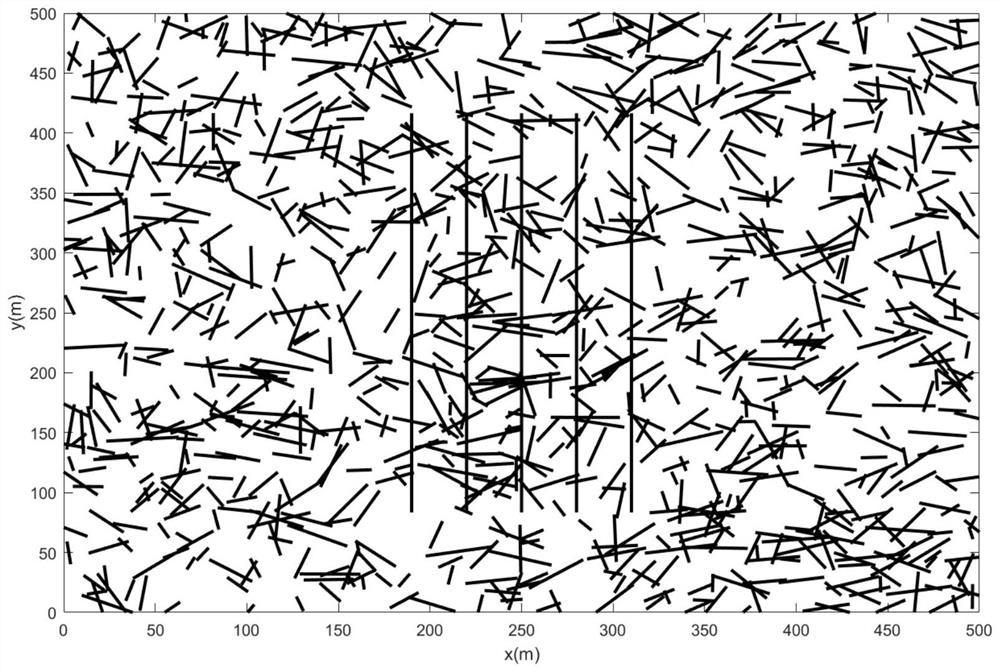

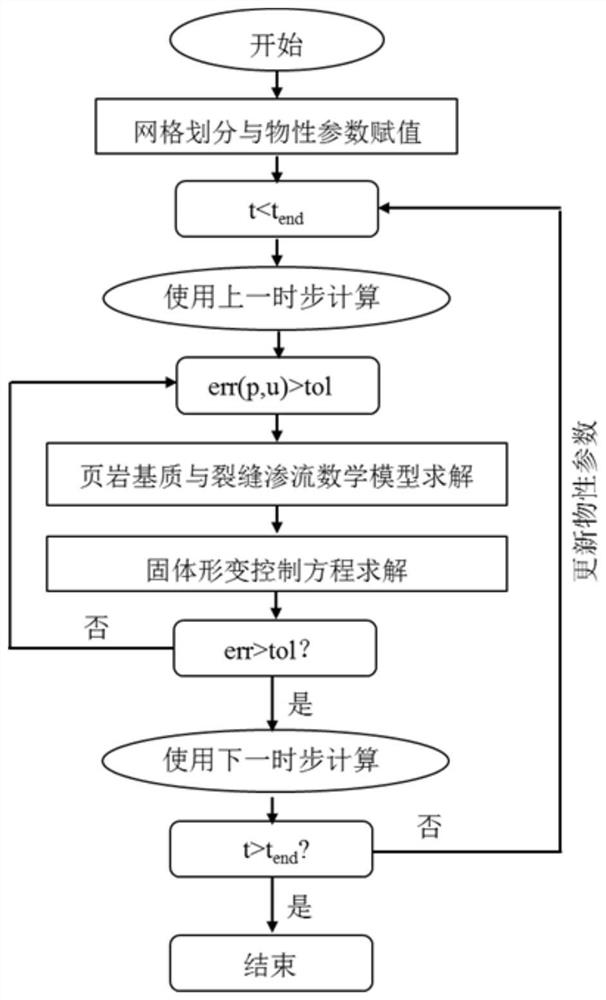

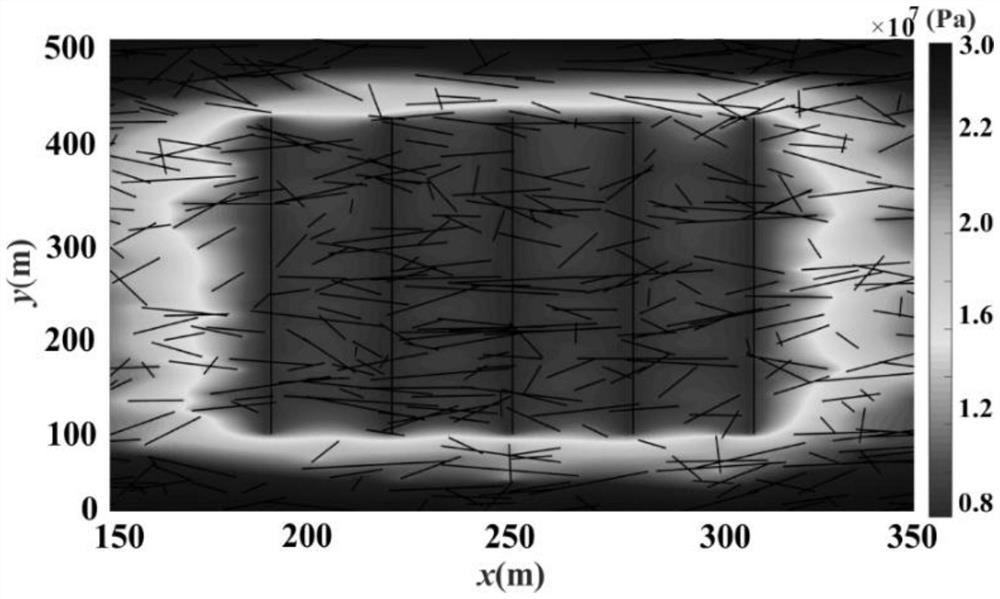

[0061] Since the current conventional oil and gas refracturing technology does not consider complex fracture distribution and multi-scale flow mechanism, it is not suitable for shale gas reservoirs with developed natural fractures and low porosity and low permeability. In order to solve the above technical problems, this embodiment provides a production-induced stress analysis method before repeated fracturing of shale gas reservoirs. In this method, it is known that the partial flow area of a typical shale gas reservoir has a size of 500m×500m×40m, within which there are 1300 natural fractures with a length of 5-15m randomly distributed, and 5 fractures distributed in the reservoir. hydraulic fractures parallel to each other with a spacing of 30m, such as figure 1 shown. Under the above background, the analysis method of production-induced stress before repeated fracturing of shale gas reservoir adopted in this embodiment includes the following steps:

[0062] Step 1: Est...

Embodiment 2

[0175] This embodiment provides a system corresponding to the production-induced stress analysis method before repeated fracturing of shale gas reservoirs described in Embodiment 1, including:

[0176] The permeability model establishment module is used to establish the multi-scale pore seepage apparent permeability model of shale gas reservoir;

[0177] Coupling model establishment module, used to establish fracture-matrix and fracture-fracture flow coupling models of shale gas reservoirs;

[0178] A seepage model establishment module, used to establish a multi-scale fluid-solid coupled horizontal well in a shale gas reservoir according to the shale gas reservoir multiscale pore seepage apparent permeability model and the shale gas reservoir flow coupling model seepage model;

[0179] The model parameter module is used to store physical parameters and assign parameters to each model;

[0180] The numerical processing module is used to perform numerical processing by using t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com