Semiconductor manufacturing scheduling method and system and computer readable storage medium

A semiconductor and random sequence technology, applied in the field of semiconductor manufacturing scheduling methods, systems, and computer-readable storage media, can solve problems such as large amount of calculations and time-consuming solutions, so as to reduce production costs, rationally allocate production capacity, and improve The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] This embodiment takes a semiconductor manufacturing scheduling method and system as an example, and the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

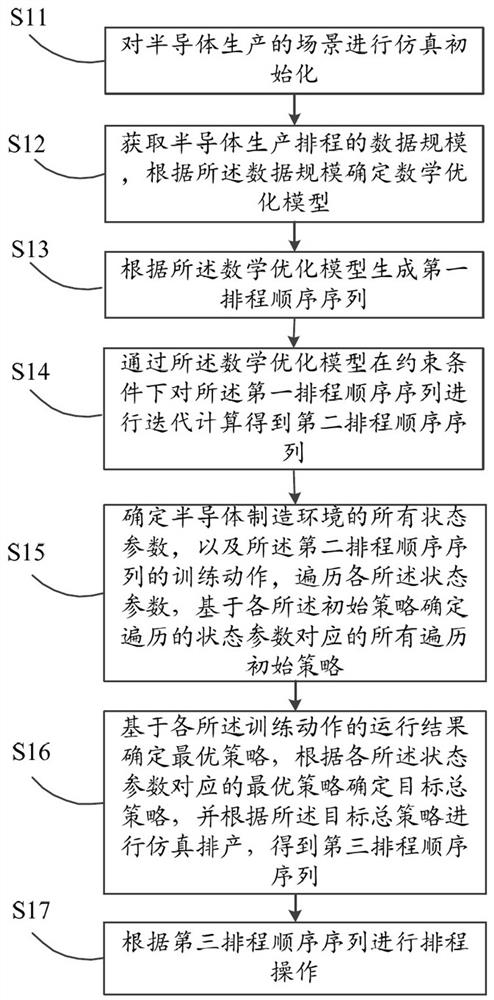

[0050] A semiconductor manufacturing production scheduling method provided by an embodiment of the present invention includes the following steps:

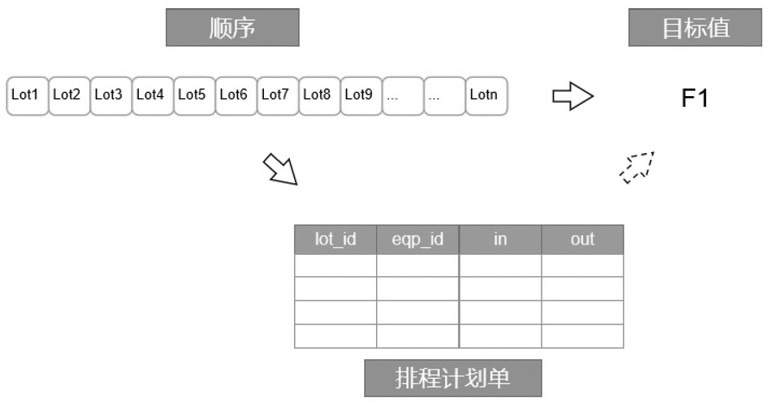

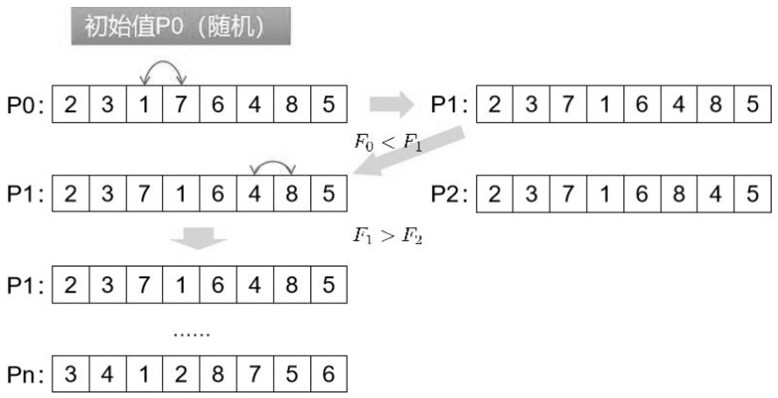

[0051] Obtaining the data scale of semiconductor manufacturing scheduling, determining a mathematical optimization model according to the data scale; generating a first scheduling order sequence according to the mathematical optimization model, and using the mathematical optimization model to perform the first scheduling under constraints Performing iterative calculation on the sequence sequence to obtain the second schedule sequence sequence, the second schedule sequence sequence is the schedule sequence sequence with the largest adaptive value under the constraints, and the constraints include the maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com