Secondary wiring fixed-distance wire stripping assist device

A secondary wiring and auxiliary device technology, applied in the direction of line/collector parts, connections, rulers for direct reading, etc., can solve problems such as stripping distances that do not meet wiring requirements, measurement errors, leakage, etc., and achieve shortening The effect of meter installation and connection time, avoiding the risk of personal injury, and precise distance stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

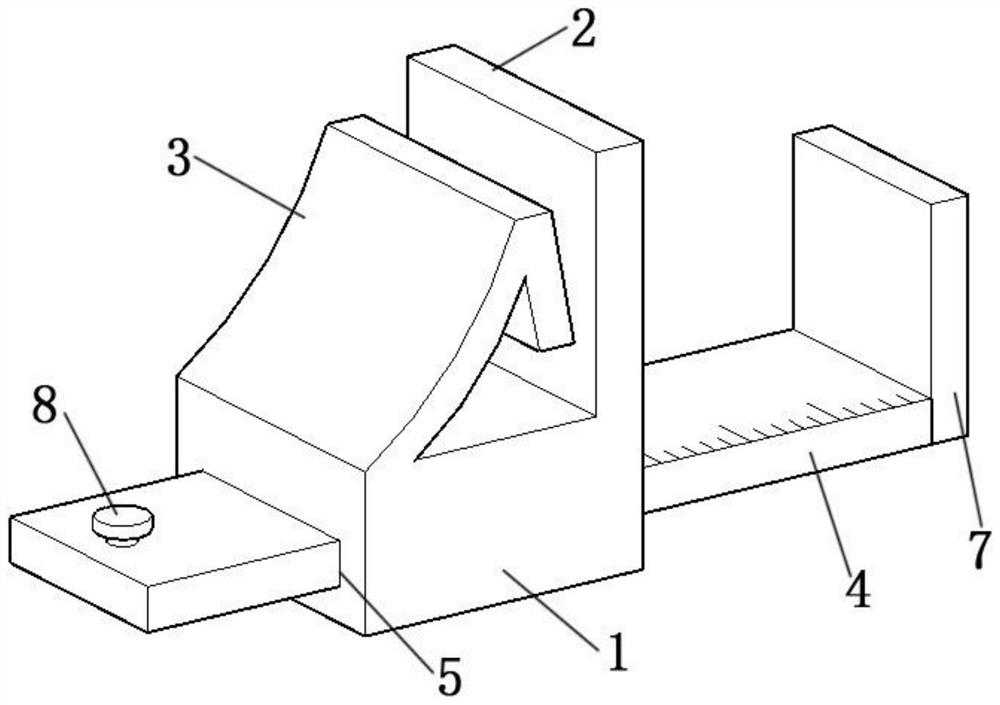

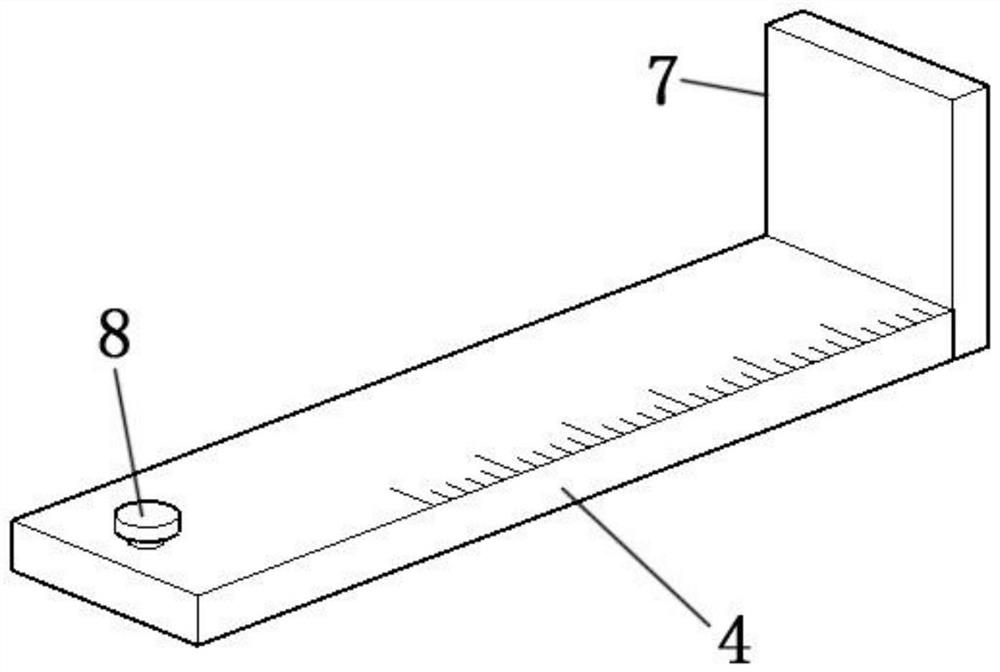

[0023] like Figure 1 to Figure 4 As shown, the secondary wiring fixed-distance wire stripping assistant includes a base 1, a fixing plate 2 is arranged on the rear side of the upper surface of the base 1, and an elastic card 3 is arranged on the front side of the upper surface of the base 1, so that The clamping assembly 3 cooperates with the fixed plate 2 to realize the clamping of the wire stripper 9, a measuring ruler 4 is arranged on the front surface of the base 1, and a chute 5 is provided through the front surface of the base 1, so The measuring ruler 4 is slidably arranged in the chute 5, and a limit plate 7 is fixedly arranged at one end of the measuring ruler 4, which is used to limit the length of the stripped wire. The other end of the measuring ruler 4 is provided with a The limit screw 8 threaded with the measuring ruler 4 is used to limit the sliding distance of the measuring ruler 4 and prevent it from slipping out of the chute 5. A threaded hole is arranged a...

Embodiment 2

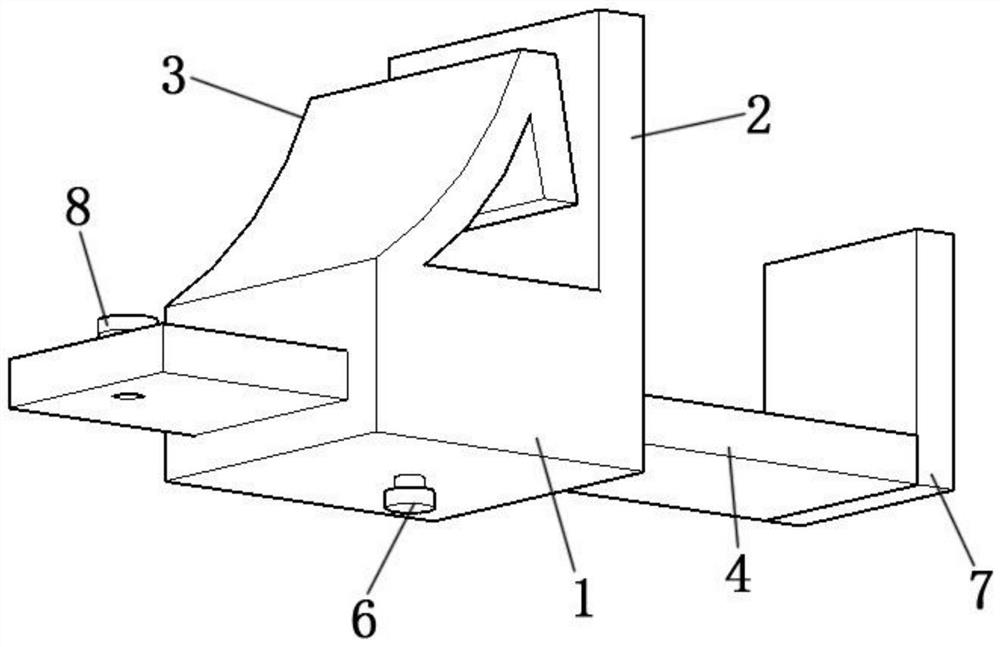

[0025] like Figure 5 and Image 6 As shown, the secondary wiring fixed-distance wire stripping assistant includes a base 1, a fixing plate 2 is arranged on the rear side of the upper surface of the base 1, and an elastic card 3 is arranged on the front side of the upper surface of the base 1, so that The clamping assembly 3 cooperates with the fixed plate 2 to realize the clamping of the wire stripper 9, a measuring ruler 4 is arranged on the front surface of the base 1, and a chute 5 is provided through the front surface of the base 1, so The measuring ruler 4 is slidably arranged in the chute 5, and a limit plate 7 is fixedly arranged at one end of the measuring ruler 4, which is used to limit the length of the stripped wire. The other end of the measuring ruler 4 is provided with a The limit sleeve 8 inserted into the measuring ruler 4 is used to limit the sliding distance of the measuring ruler 4 and prevent it from slipping out of the chute 5. A threaded hole is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com