Moisturizing silk stockings and production process thereof

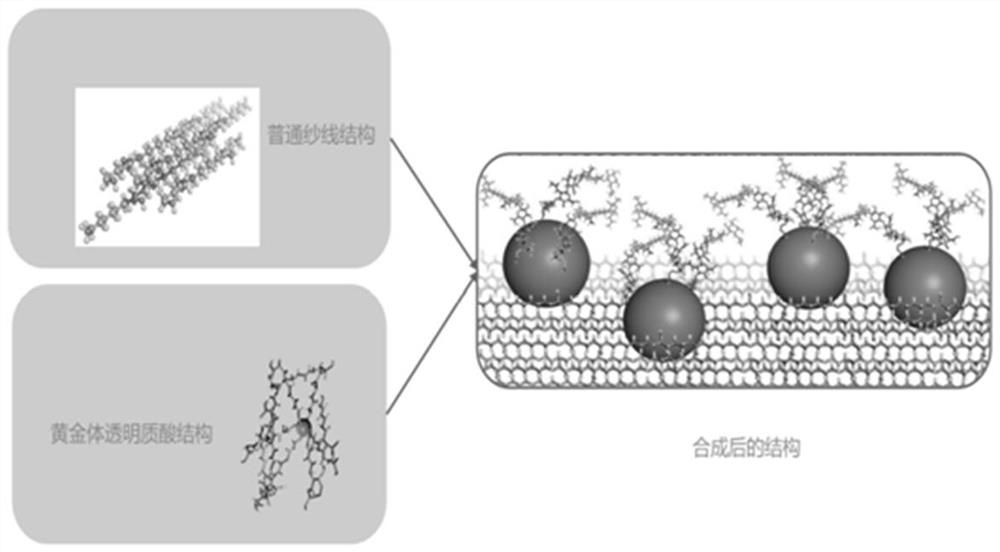

A production process and technology of stockings, which is applied in the field of hydrating stockings and its production process, can solve the problems of inability to re-produce moisturizing, moisturizing, unstable mask nutrient solution, discounted use effect, etc., and achieve good moisturizing effect and good moisturizing effect , to promote the effect of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

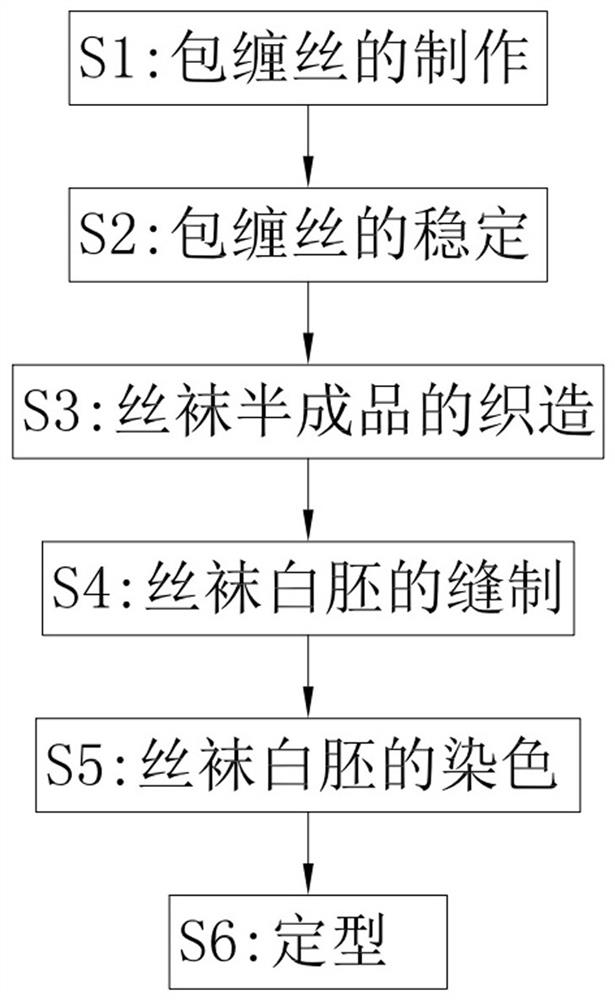

[0037] In Example 2, a production process for moisturizing silk stockings includes the following steps: S1: making wrapping silk: select the spandex wrapping silk of the anti-falling off 20D model and the gold sodium hyaluronate nylon of the FDY11 / 7 model to contain The nylon of the golden sodium hyaluronate particles is covered with silk, which is double-wrapped, and the wrapping direction of the two layers of nylon is opposite; the motor speed is 23000 rpm, the draft ratio is 2.5, the twist is 1400T / M, and the overfeed is 95% , the working temperature is 20°C and the humidity is 45%.

[0038] S2: Stability of wrapping silk: the wrapping silk after making is balanced wrapping silk under the environment of 35 ℃, and balance time is greater than 12 hours;

[0039] S3: Weaving of semi-finished stockings: weaving the balanced wrapping silk through a sock knitting machine to make semi-finished stockings;

[0040] S4: Sewing of the white stockings: the semi-finished stockings are ...

Embodiment 3

[0043] In Example 3, a production process for hydrating stockings includes the following steps: S1: Production of wrapping silk: select the spandex wrapping silk of the anti-scattering 20D model and the gold sodium hyaluronate nylon of the FDY11 / 7 model to contain The nylon of the golden sodium hyaluronate particles is covered with silk, which is double-wrapped. The wrapping directions of the two layers of nylon are opposite; the motor speed is 25,000 rpm, the draft ratio is 3.0, the twist is 1500T / M, and the overfeed is 95%. , the working temperature is 30°C and the humidity is 55%.

[0044] S2: Stability of wrapping silk: the wrapping silk after making is balanced wrapping silk under the environment of 45 ℃, and balance time is greater than 12 hours;

[0045] S3: Weaving of semi-finished stockings: weaving the balanced wrapping silk through a sock knitting machine to make semi-finished stockings;

[0046] S4: Sewing of the white stockings: the semi-finished stockings are st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com