Uniform mixing device for processing hydroxypropyl acrylate

A hydroxypropyl acrylate, mixing technology, used in mixers, transportation and packaging, shaking/oscillating/vibrating mixers, etc., can solve problems such as container damage and increase the cost of container use, reduce damage and improve mixing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

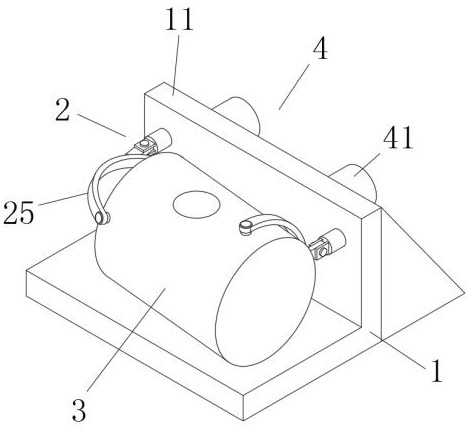

[0030] Example 1: Reference Figure 1-4 , a kind of hydroxypropyl acrylate processing mixing device, comprising a support member 1, the support member 1 comprising a support plate 11, the support plate 11 is provided with a connecting component 2, the connecting assembly 2 active connection mixing cylinder 3, the connection assembly 2 fit through the support plate 11 connected to the drive assembly 4, the drive assembly 4 is mounted on the other side of the support plate 11.

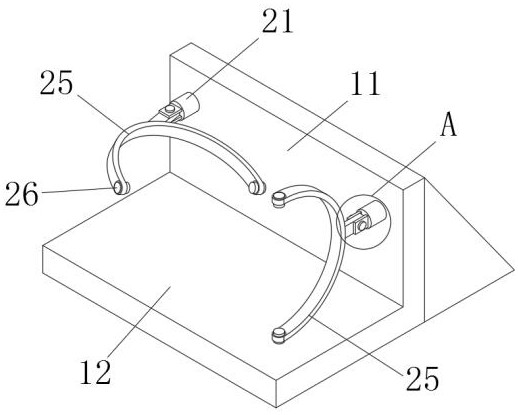

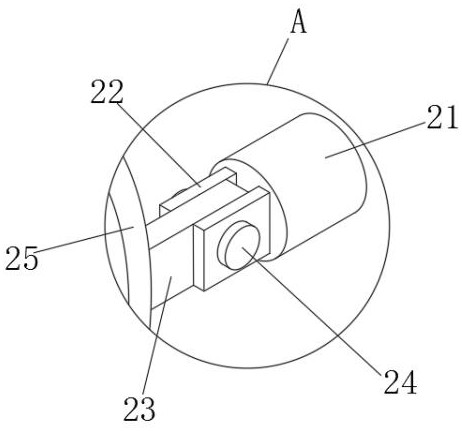

[0031]The connecting assembly 2 comprises a symmetrically disposed lever 21, the lever 21 rotates through the support plate 11, the other end of the lever 21 is fixed to connect the two splints 22 ends, the two splints 22 form a cavity, the cavity is provided with a connecting plate 23, the connecting plate 23 on both sides of the spline 24 rotation connection of the splint 22, and the connecting plate 23 ends of the active connection bearing.

[0032] The load bearing member comprises a semi-circular arc br...

Example Embodiment

[0034] Example TWO: On the basis of example one, the drive assembly 4 is replaced with an intermittent motion structure, i.e., the drive assembly 4 comprises a motor 41, the motor 41 drives the connection to the first gear 42, the first gear 42 bites the incomplete gear 43, the incomplete gear 43 is connected to the middle of the rod 21, the proportion of the working tooth surface and the working surface of the incomplete gear 43 is 3:1, the use of intermittent drive so that the mixing cylinder 3 to achieve a shaking - stop - shaking state, Reduce the impact of the continuous shaking liquid on the inner wall of the shaking cylinder 3, and can make the liquid buffer to shake it, improve the mixing efficiency. The gears are mounted on the side of the support plate 11.

Example Embodiment

[0035] Example THREE: on the basis of Example I or Example II, reference is made Figure 5 , the mixing cylinder 3 inner wall is provided with a plurality of annular plates 31, the annular plate 31 is provided with a plurality of tooth plates 32, but also in the mixing cylinder 3 at the central axis of the mixing rod is provided, drive the stirring rod to stir, when shaking around the ring plate 31 on the tooth plate 32 will further accelerate the mixing.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap