Heat treatment process for carburizing bearing steel

A carburizing bearing and bearing steel technology, applied in the field of carburizing bearing steel heat treatment process, can solve the problems of low production efficiency, low efficiency, long time, etc., and achieve the effect of improving production efficiency, reducing cost and improving surface structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

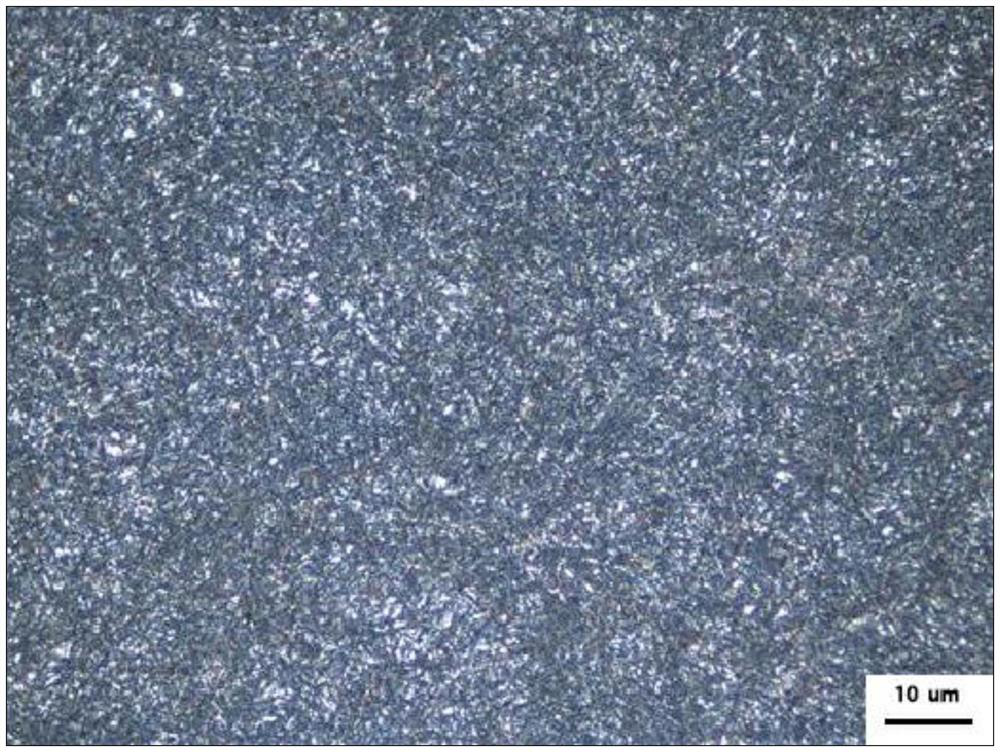

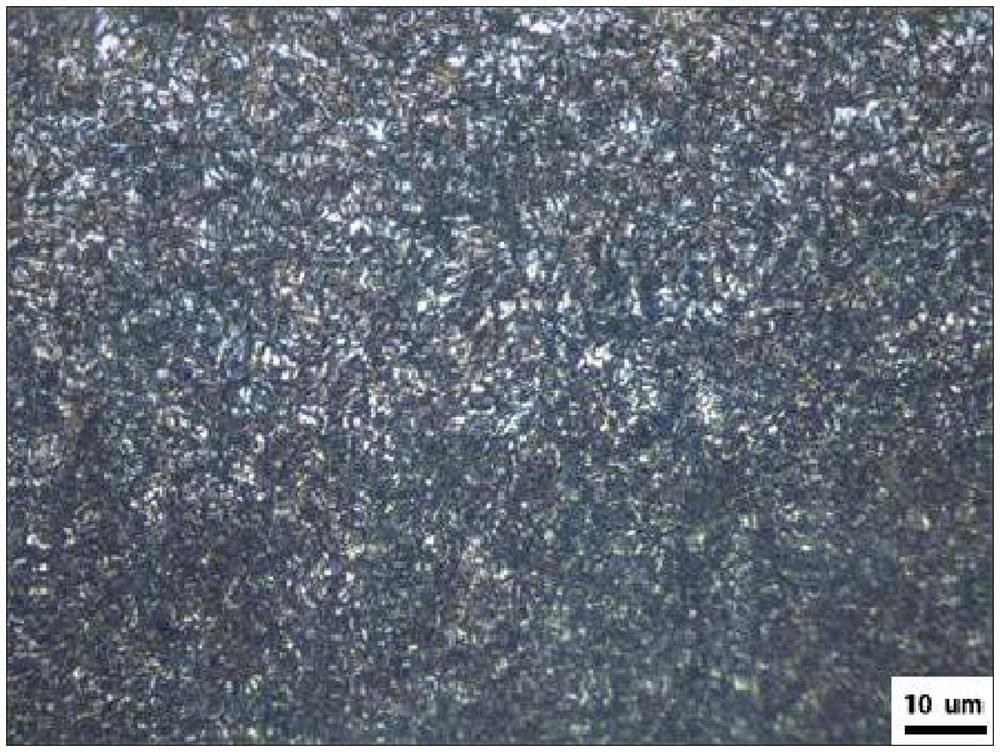

Image

Examples

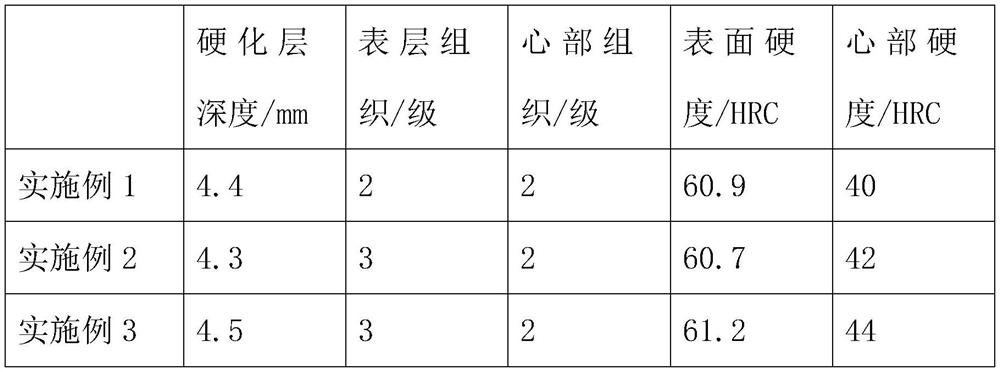

Embodiment 1

[0043] Carburized bearing steel heat treatment process, including the following steps:

[0044] Carburizing and quenching steps: start to pass RX gas for exhaust before heating up, the exhaust time is 1h, RX gas is continuously introduced throughout the whole process, and the flow rate of RX gas is 5m 3 / h;

[0045] Intensive infiltration stage: raise the temperature in the furnace to 920°C and keep it warm for 70 hours; during the heat preservation period, the set value of carbon potential is 1.2%, and the carbon potential is lower than the set value, and the natural gas flow rate is 0.2m 3 / h, the carbon potential is higher than the set value, stop feeding natural gas;

[0046] Diffusion stage: heat preservation at 940°C for 14 hours; during the heat preservation period, the carbon potential set value is 1.0%, and the carbon potential is lower than the set value, and natural gas is introduced, and the flow rate of natural gas is 0.2m 3 / h, the carbon potential is higher th...

Embodiment 2

[0053] Carburized bearing steel heat treatment process, including the following steps:

[0054] Carburizing and quenching steps:

[0055] Intensive infiltration stage: raise the temperature in the furnace to 940°C and keep it warm for 60 hours; during the heat preservation period, the set value of the carbon potential is 1.35%, and the carbon potential is lower than the set value, and the natural gas is introduced, and the flow rate of the natural gas is 0.8m 3 / h, the carbon potential is higher than the set value, stop feeding natural gas;

[0056] Diffusion stage: heat preservation at 940°C for 18 hours; during the heat preservation period, the carbon potential set value is 1.2%, and the carbon potential is lower than the set value, and natural gas is introduced, and the flow rate of natural gas is 0.8m 3 / h, the carbon potential is higher than the set value, stop feeding natural gas;

[0057] Insulation stage: lower the temperature to 880°C and keep it for 12 hours; durin...

Embodiment 3

[0064] Carburized bearing steel heat treatment process, including the following steps:

[0065] Carburizing and quenching steps:

[0066] Intensive infiltration stage: raise the temperature in the furnace to 930°C and keep it warm for 63 hours; during the heat preservation period, the set value of carbon potential is 1.3%, and the carbon potential is lower than the set value, and natural gas is introduced, and the flow rate of natural gas is 0.5m 3 / h, the carbon potential is higher than the set value, stop feeding natural gas;

[0067] Diffusion stage: heat preservation at 920°C for 15 hours; during the heat preservation period, the set value of carbon potential is 1.0%, and the carbon potential is lower than the set value, and natural gas is introduced at a flow rate of 0.5m 3 / h, the carbon potential is higher than the set value, stop feeding natural gas;

[0068] Insulation stage: lower the temperature to 880°C and keep the temperature for 10 hours; during the insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com