Four-way ball valve operating mechanism capable of avoiding misoperation

An operating mechanism, misoperation technology, applied in the direction of preventing accidental or unauthorized action, valve operation/release device, valve details, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

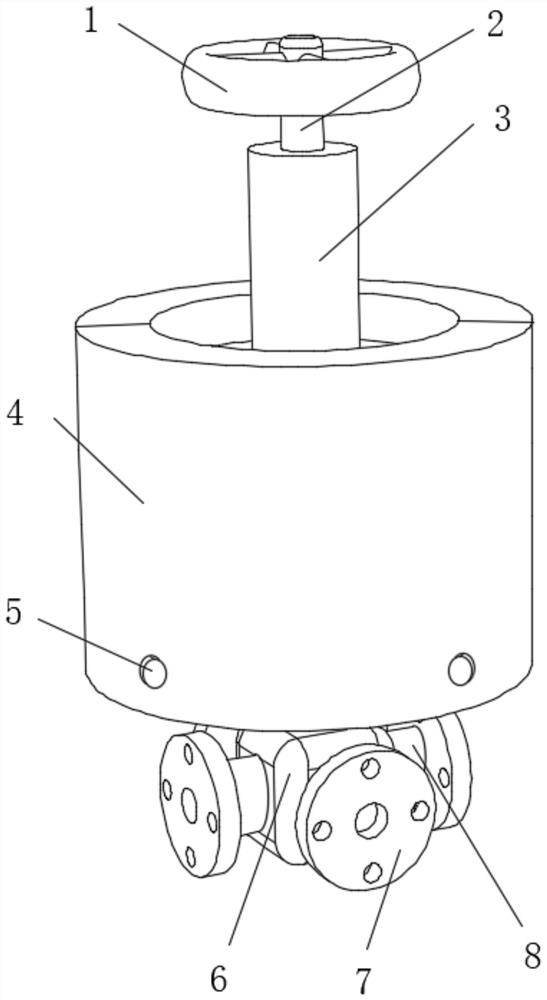

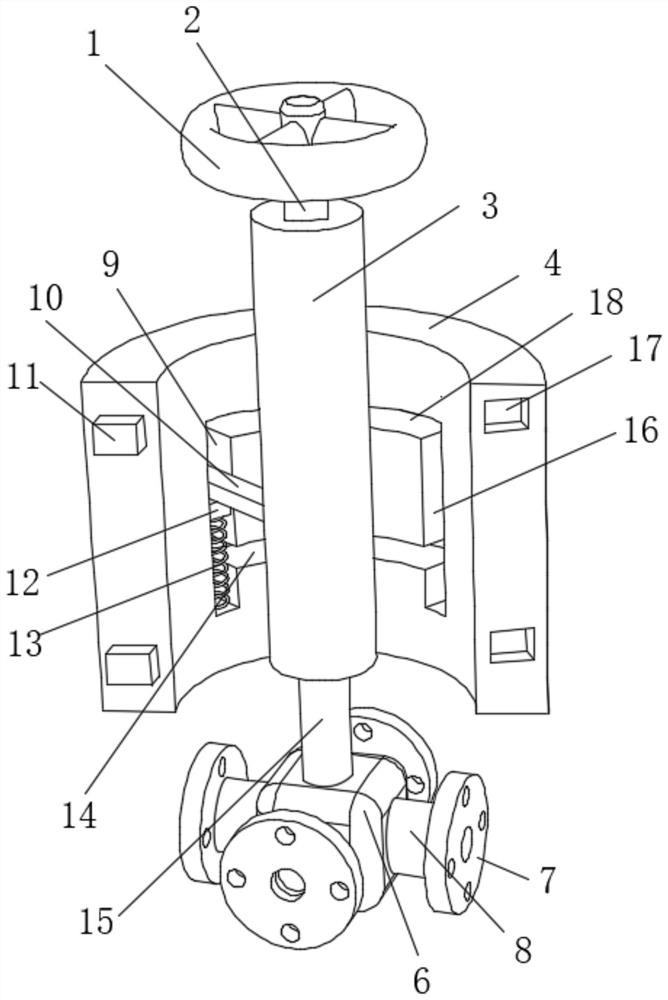

[0031] refer to Figure 1-8 , a four-way ball valve operating mechanism that can avoid misoperation, including a valve body 6 and two semi-cylindrical shells 4, a valve stem 15 is arranged inside the valve body 6, and the top of the valve stem 15 extends above the valve body 6 , the four sides of the valve body 6 are fixedly connected with a connected connecting pipe 8, one end of the connecting pipe 8 is fixedly connected with a flange 7, the outer wall sliding sleeve of the valve stem 15 is provided with a sleeve 3, and the top of the sleeve 3 is fixed A fixed rod 2 is connected, the top of the fixed rod 2 is fixedly connected with a hand wheel 1, the outside of the sleeve 3 is fixedly connected with two symmetrically arranged connecting rods 10, and the inner side of the semi-cylindrical shell 4 is provided with a control rod 10 to move. As for the limiting component, the semi-cylindrical shell 4 is arranged above the valve body 6 , and the top of the connecting pipe 8 is p...

Embodiment 2

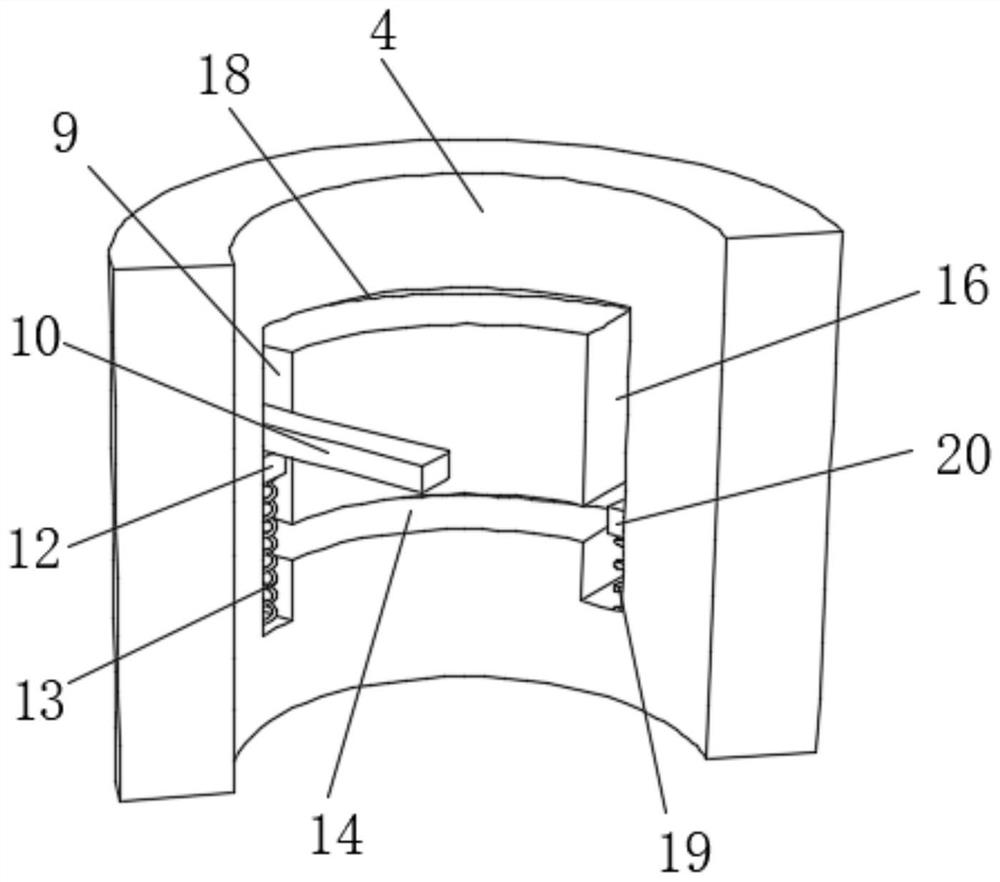

[0033] refer to Figure 1-8, a four-way ball valve operating mechanism that can avoid misoperation, including a valve body 6 and two semi-cylindrical shells 4, a valve stem 15 is arranged inside the valve body 6, and the top of the valve stem 15 extends above the valve body 6 , the four sides of the valve body 6 are fixedly connected with a connected connecting pipe 8, one end of the connecting pipe 8 is fixedly connected with a flange 7, the outer wall sliding sleeve of the valve stem 15 is provided with a sleeve 3, and the top of the sleeve 3 is fixed A fixed rod 2 is connected, the top of the fixed rod 2 is fixedly connected with a hand wheel 1, the outside of the sleeve 3 is fixedly connected with two symmetrically arranged connecting rods 10, and the inner side of the semi-cylindrical shell 4 is provided with a control rod 10 to move. The limit assembly, the limit assembly includes a second transverse groove 18 opened on the inside of the semi-cylindrical housing 4, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com