Stainless steel low-smoke furnace and operation method thereof

A stainless steel, smoke stove technology, applied in household stoves/stoves, solid heating fuels, lighting and heating equipment, etc., can solve problems such as affecting the combustion of firewood, containment, user discomfort, etc., to reduce smoke, avoid discomfort, and avoid looseness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

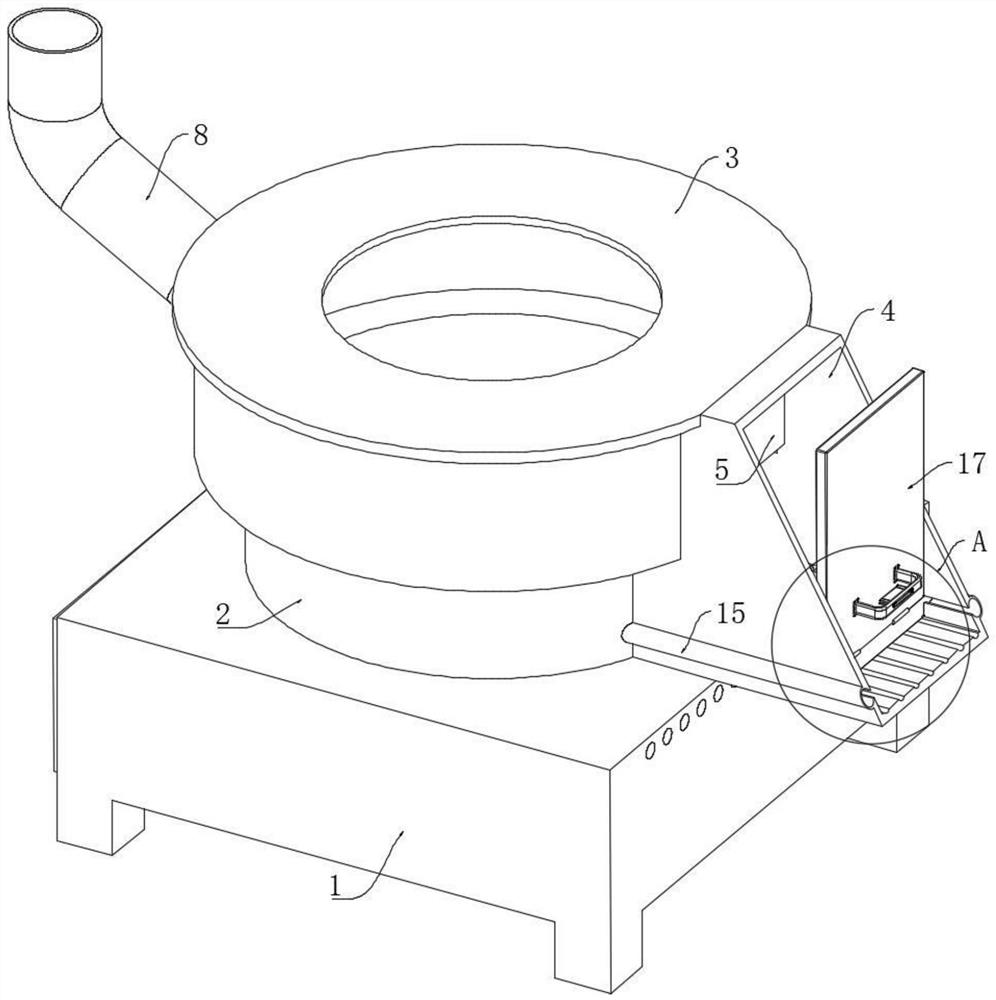

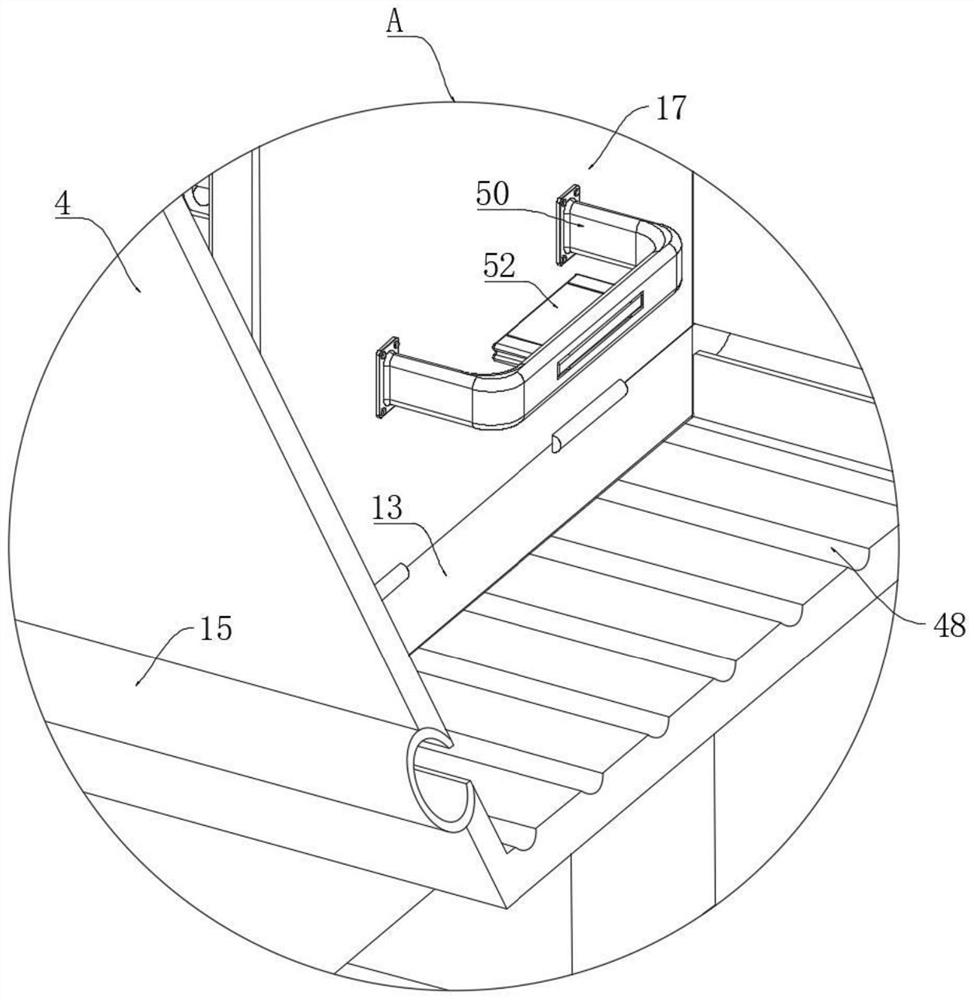

[0052] As an embodiment of the present invention, the ash collection device includes a plurality of first straight rods 7, and all the first straight rods 7 are fixed in an array inside the ash drop opening 6, and all the first straight rods 7 are provided with insertion slots inside 10. A second straight rod 11 is inserted inside the insertion groove 10, the bottom of the second straight rod 11 runs through the side wall of the first straight rod 7, and all the second straight rods 11 are fixed at the bottom of one end of the chimney 8. Cross bar 12, all the second straight bars 11 are equipped with a pulling feeding mechanism towards the end of the feeding frame 4, the pulling feeding mechanism is used to drive the second straight bar 11 to move, and the top of the cross bar 12 is equipped with a device for driving the ashes to fall. Toggle mechanism, between the cross bar 12 and the third inner groove 36, an ash pressing mechanism for leveling and reclaiming the ashes is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com