Device and method for testing waterproof performance of reduction gearbox

A testing device and gear box technology, applied in liquid/vacuum measurement for liquid tightness, by detecting the appearance of fluid at the leak point, etc., can solve the problems of inability to simulate the impact, time-consuming, labor-intensive, and after-sales problems. , to achieve the effect of shortening the development cycle and cost, high test safety, and realizing repeated use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

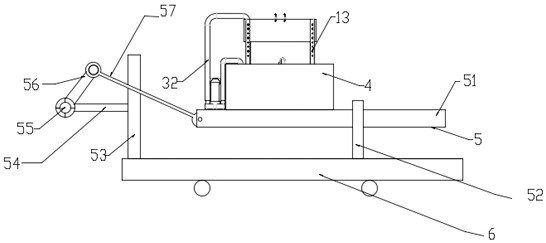

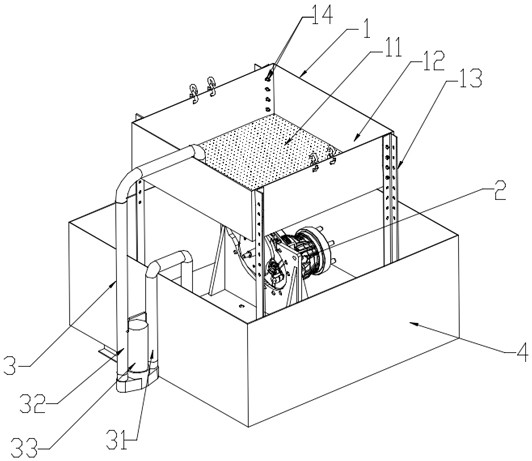

[0036] Such as Figure 1-4 As shown, a waterproof performance test device of a gearbox in this embodiment includes a test device 1 , a sample to be tested 2 , a water pump structure 3 , a water storage tank 4 , and a shaking mechanism 5 .

[0037] The tested sample 2 is set in the reservoir 4 .

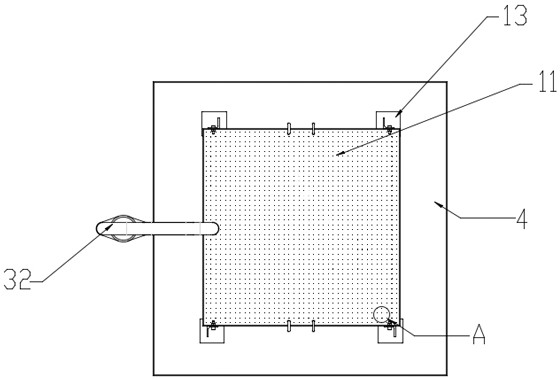

[0038] The test device 1 includes a water shower device 11, a water shower tank 12, a support structure 13, and a fastener 14; the test device 1 is arranged in the reservoir 4, above the sample to be tested 2; the water shower device 11 is arranged in the test device 1 Lower end; during specific implementation, the water shower device 11 is arranged inside or at the bottom of the water shower tank 12, and the water shower tank 12 is fixed above the water shower device 11. When water is poured into the water shower tank 12, the water flows through the water shower device 11 to the sample 2 to be tested. Above; the support structure 13 is provided with a plurality of waist-shaped holes...

Embodiment 2

[0043] Such as Figure 1-4 As shown, the test method for the waterproof performance test of a gear box of this embodiment is applied to the test device of the above-mentioned embodiment 1, and the steps are as follows:

[0044] (a) Place the tested sample 2 in the reservoir 4, the tested sample 2 is placed under the test device 1, and the tested sample 2 is placed in the vehicle installation posture;

[0045] (b) Adjust the preset heights of the shower tank 12 and the shower device 11;

[0046] (c) Inject water into the reservoir 4;

[0047] (d) Turn on the water pump 33 so that the water in the reservoir 4 is sucked from the water inlet pipe 31 and discharged from the water outlet pipe 32 into the water shower tank 12, and the water flows through the water shower device 11 onto the sample 2 to be tested;

[0048] (e) Turn on the switch of the shaking mechanism 5 to make the reservoir 4 shake from side to side, simulating the shaking effect of the reduction box when the car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com