Automatic pressure test pump and water stamping test equipment

A pressure test pump, automatic technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve problems such as the inability of the water pressure to remain stable, the error of the measured data, and the low efficiency of manual water delivery. , to achieve the effect of improving pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

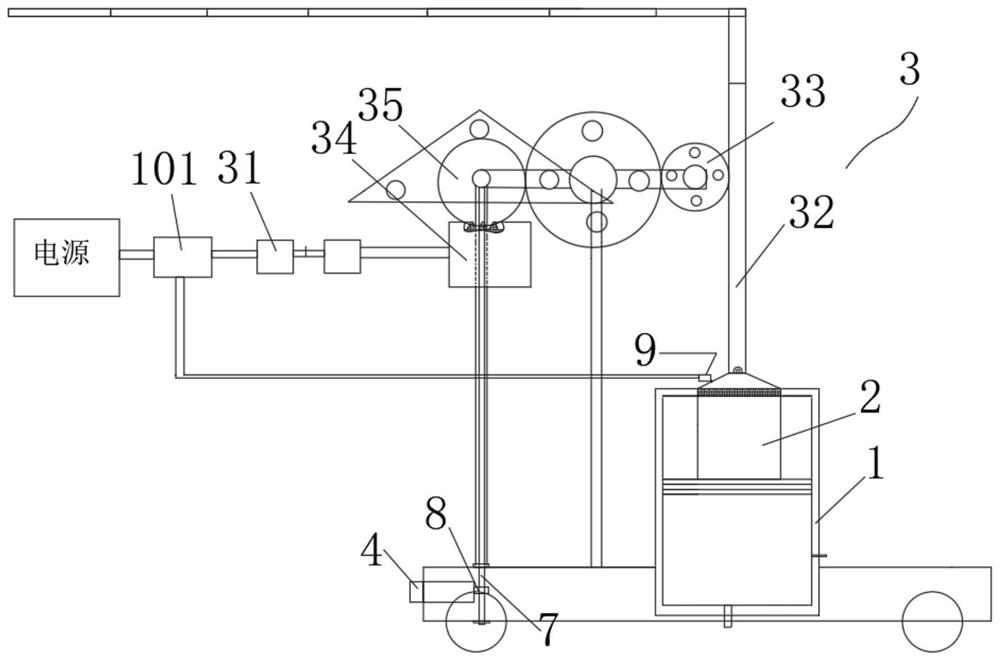

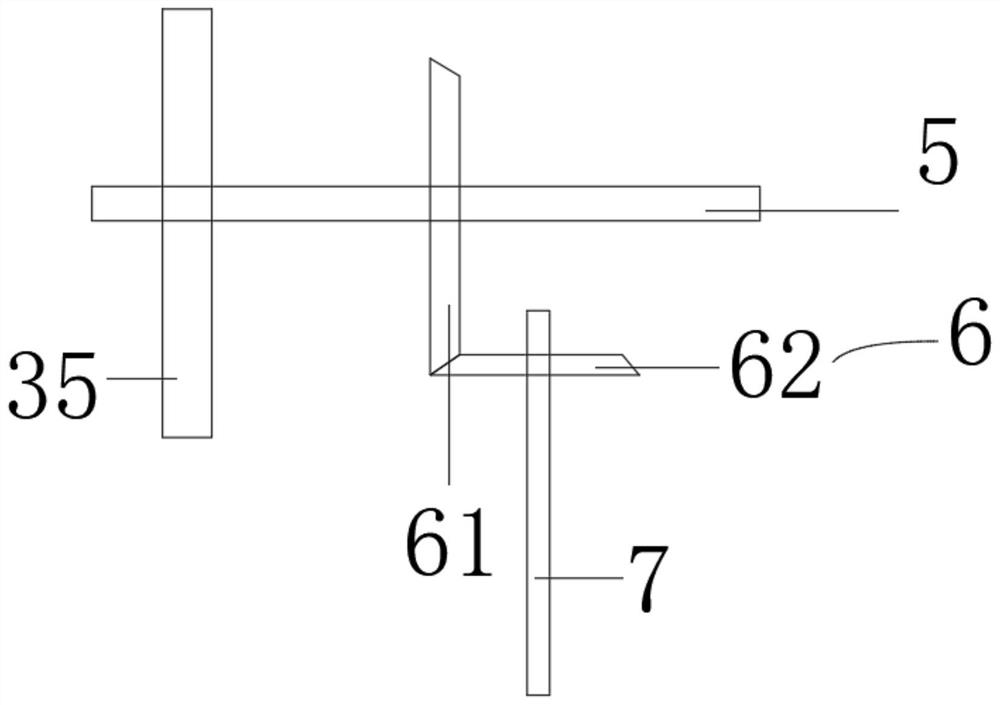

[0043] This embodiment describes an automatic pressure test pump, see figure 1, the automatic pressure test pump includes a pump box 1 and a driving mechanism 3, wherein the pump box 1 has a housing chamber, a pump body 2 is arranged in the housing chamber, and the driving mechanism 3 includes a driver 31 and a lifting part 32, wherein the lifting part 32 and The pump body 2 is connected, and the lifting member 32 is driven by the driver 31 to move up and down, so as to drive the pump body 2 to move up and down in the accommodating cavity. The driving mechanism 3 includes a lifting part 32 and a driver 31. The lifting part 32 is connected with the pump body 2. Under the drive of the driver 31, the lifting part 32 performs a lifting movement to drive the pump body 2 to perform a lifting movement in the accommodating chamber, realizing the pump body 2. The pumping process of the body 2 overcomes the manual pumping process and improves the pumping efficiency, and the continuous w...

Embodiment 2

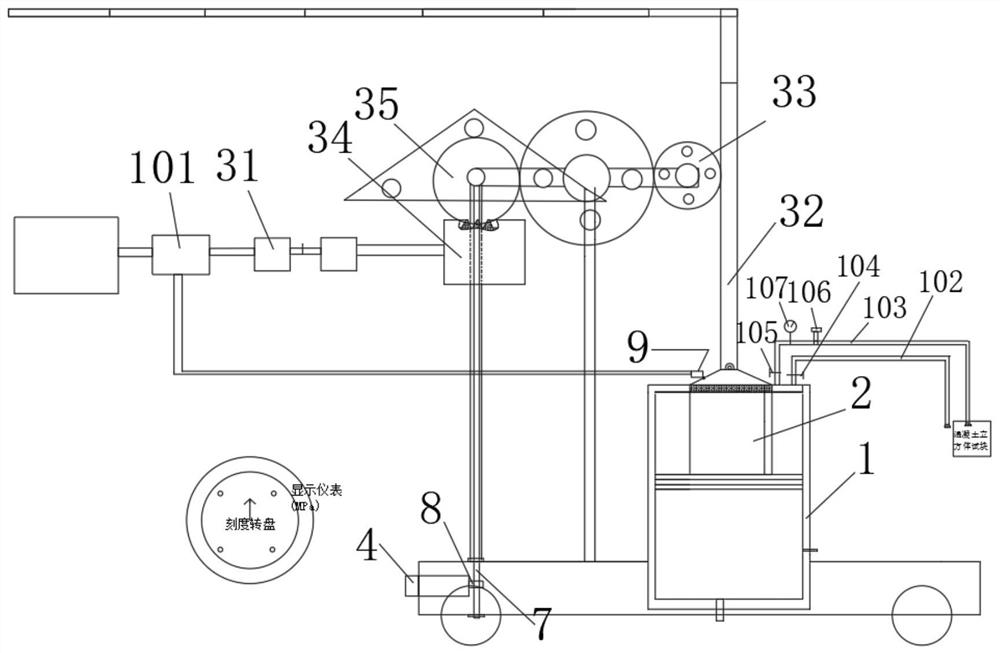

[0049] This embodiment describes an automatic pressure test pump, which differs from Embodiment 1 in that, see figure 1 , the automatic pressure test pump in this embodiment further includes a pressure sensor 9 disposed on the pump body 2 and a controller 101 electrically connected to the pressure sensor 9 . The pressure sensor 9 is used to measure the water pressure of the pump body 2 without manual calculation, and the controller 101 is electrically connected to the pressure sensor 9. In actual use, a pressure value P is preset first. When the pressure sensor 9 detects that the water pressure in the pump box 1 is greater than P, the power supply of the drive motor can be cut off immediately through the controller 101, and then the rack stops the lifting movement, so that the pump body 2 no longer works, and the operation is rapid without manual labor. Monitoring the water pressure in the pump box 1 is easy to use. Specifically, the staff selects the pressure sensor 9 and the...

Embodiment 3

[0051] This embodiment describes a water stamping test equipment, which differs from Embodiment 1 and Embodiment 2 in that, see figure 2 , the water stamping test equipment of the present implementation includes an automatic pressure test pump, a water inlet pipeline 102 and a water outlet pipeline 103, wherein the automatic pressure test pump is an automatic pressure test pump as described above, and the water inlet pipeline 102 and the water outlet pipeline 103 are communicated with the receiving chamber respectively, and a first valve 104 and a second valve 105 are respectively added on the pipelines of the water inlet pipeline 102 and the water outlet pipeline 103, and the first valve 104 and the second valve 105 are set as one-way valves, wherein The water inlet pipeline 102 is connected with an external water source, and the water outlet pipeline 103 is connected with the cubic stone to be tested for water stamping. When starting the test, first add water continuously to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com