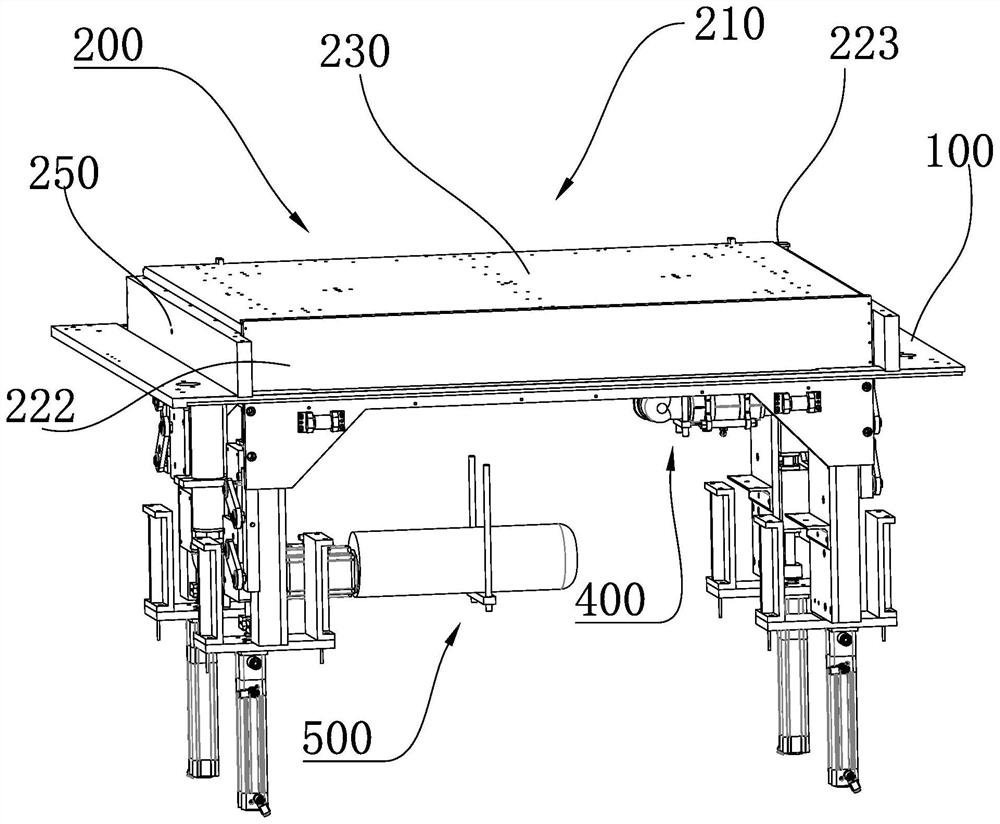

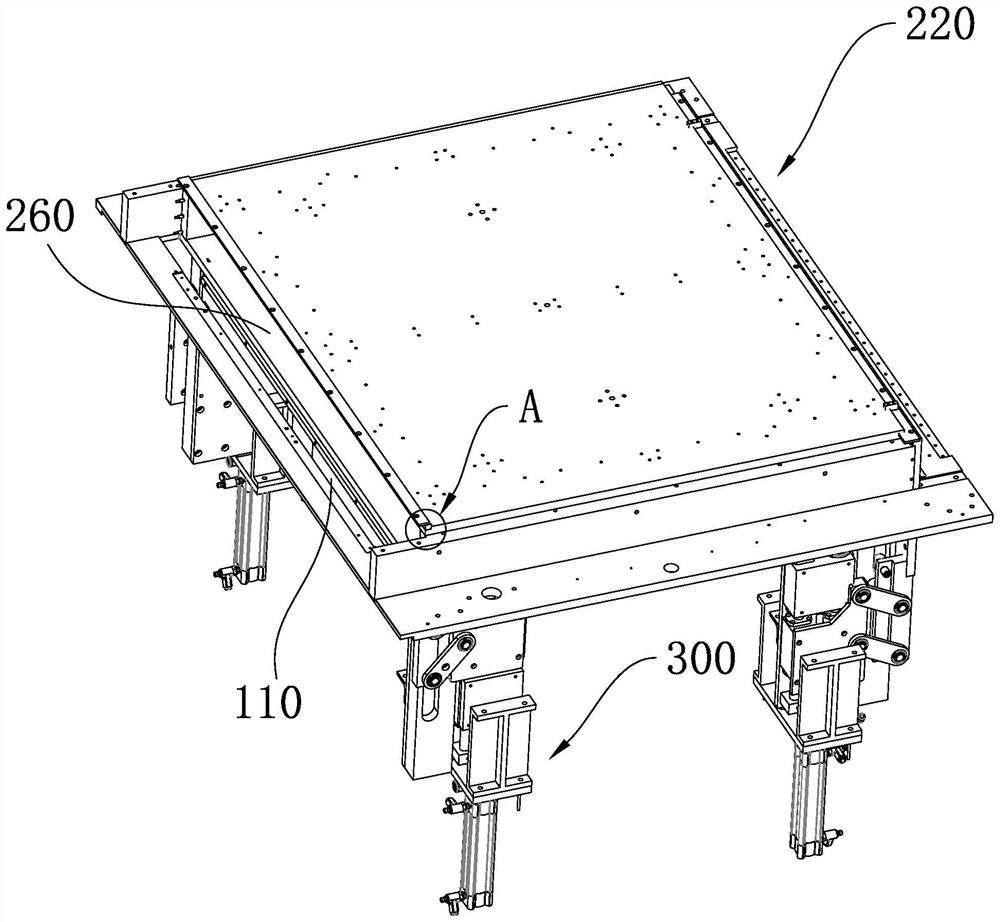

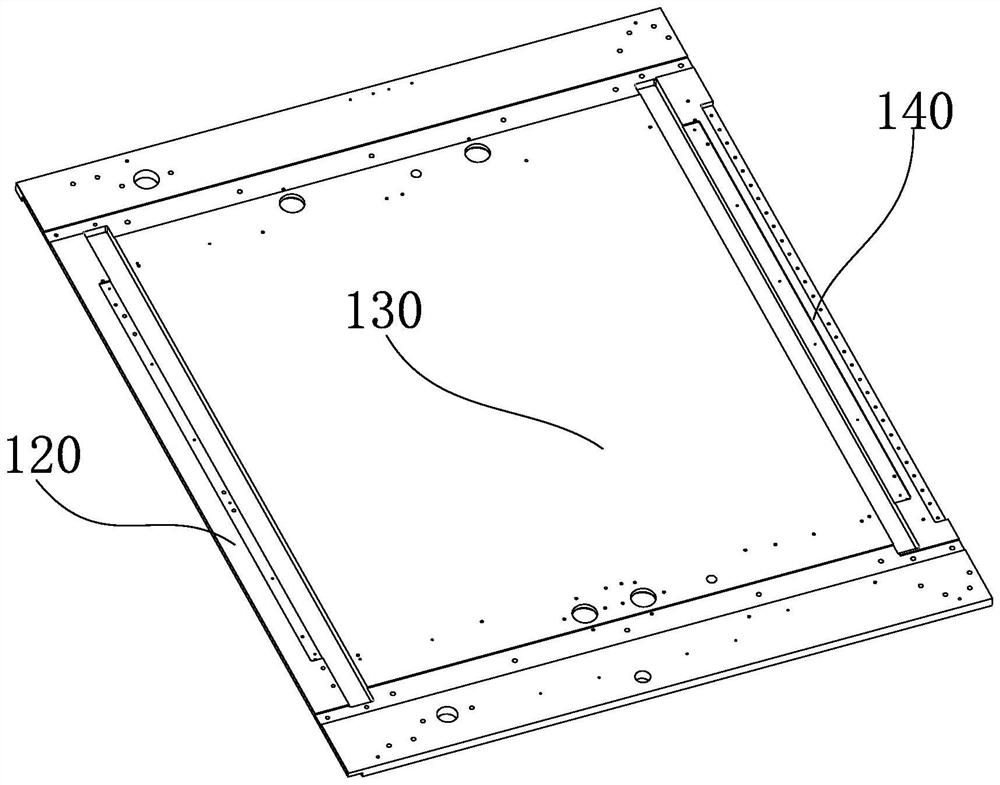

Battery vacuum liquid suction device and control method thereof

A vacuum suction and battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of inconvenient transportation, manufacturing difficulties, performance degradation, etc., and achieve the effect of good sealing effect, easy processing, and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0080] The present invention also provides a control method for a battery vacuum cover liquid suction device, based on the battery vacuum liquid suction device described in Embodiment 1, comprising the steps of:

[0081] S1: Open the vacuum cover through the lifting movement of the movable plate in the vertical direction, and wait for the liquid-absorbing battery to be input into the liquid-absorbing part;

[0082] S2: closing the vacuum cover through the lifting movement of the movable plate in the vertical direction;

[0083] S3: The controller controls the vacuum component to vacuumize the chamber, and monitors the real-time vacuum degree in the chamber through a vacuum gauge;

[0084] S4: Send the monitored real-time vacuum degree to the controller through the vacuum gauge, and judge whether the real-time vacuum degree reaches the preset vacuum degree through the controller, if yes, go to step S5, if not, continue vacuuming;

[0085] S5: Control the vacuum component to st...

Embodiment 3

[0090] The present invention also provides a control method for a battery vacuum cover liquid suction device, based on the battery vacuum liquid suction device described in Embodiment 1, comprising the steps of:

[0091] S1: Open the vacuum cover through the lifting movement of the movable plate in the vertical direction, and wait for the liquid-absorbing battery to be input into the liquid-absorbing part;

[0092] S2: closing the vacuum cover through the lifting movement of the movable plate in the vertical direction;

[0093] S3: the controller controls the vacuum component to evacuate the containing cavity within a preset time;

[0094] S4: stop the work of the vacuum component, and control the release of the vacuum component by the controller to release the vacuum in the chamber until the internal and external atmospheric pressures are consistent;

[0095] S5: Steps S3-S4 are repeatedly executed, and the number of executions is judged by the controller. If the number of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com