Method and control system for controlling compressor output of gas turbine engine

A technology for gas turbines and engines, used in engine control, turbine/propulsion fuel delivery systems, engine components, etc., to solve problems such as overspeed, reducing the severity and duration of transient conditions, compressor surge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The detailed description, set forth below in conjunction with the accompanying drawings, is intended as a description of various embodiments and is not intended to represent the only embodiments in which the invention may be practiced. The detailed description includes specific details in order to provide a thorough understanding of the embodiments. It will be apparent, however, to one skilled in the art that embodiments of the invention may be practiced without these specific details. In some instances, well-known structures and components are shown in simplified form for clarity of description.

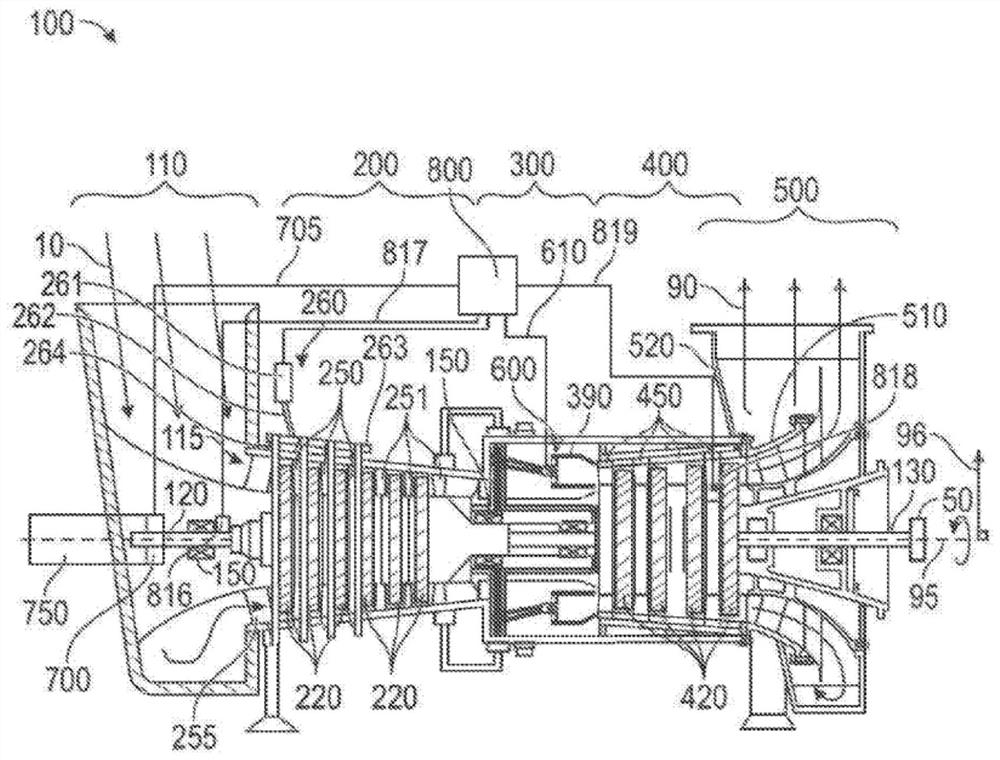

[0011] figure 1 is a schematic diagram of an exemplary gas turbine engine. Some surfaces are omitted or exaggerated for clarity and ease of illustration. Furthermore, the invention may refer to both forward and backward directions. In general, all references to "forward" and "rearward" relate to the direction of flow of the primary air (ie, the air used for the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com