Micro-tube type direct-carbon solid oxide fuel cell stack based on biomass charcoal fuel

A technology of solid oxides and fuel cell stacks, applied in fuel cells, circuits, electrical components, etc., can solve the problems of poor storage and transportation safety, low volume energy density, and inability to obtain directly, achieving low price, high energy density, The effect of avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

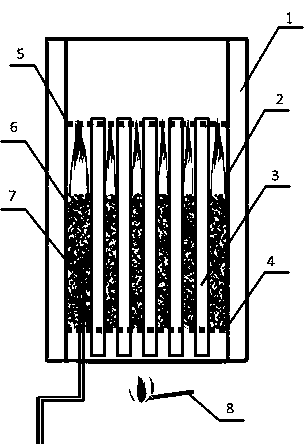

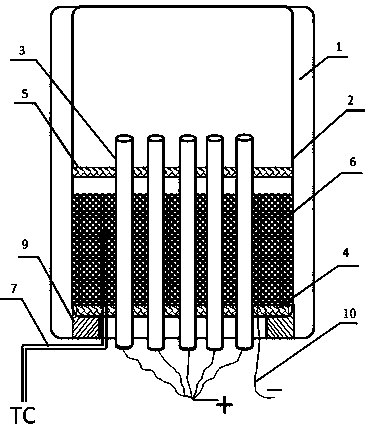

[0018] according to image 3 As shown, multiple microtube solid oxide fuel cell cells (3) are connected in parallel with silver wires (10) and their insulation conditions are checked.

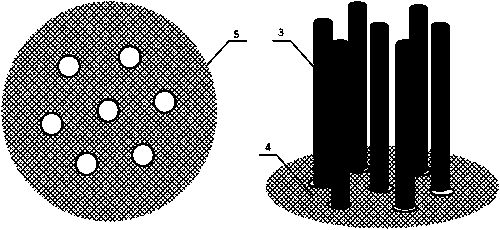

[0019] according to figure 2 As shown, the upper and lower ends of the microtube solid oxide fuel cell (3) are respectively embedded in a 12-mesh stainless steel mesh (5) and a 30-mesh stainless steel mesh (4), and are fixed with silver paste. Place the assembled microtube solid oxide fuel cell group in the reaction chamber (2), and ensure that the 30-mesh stainless steel mesh (4) is placed on the support ring (9) at the bottom of the reaction chamber (2). Add biochar (6) above the battery pack, biochar (6) falls into reaction chamber (2) through 12-mesh stainless steel mesh (5), and is supported by stainless steel mesh (4) at the bottom of reaction chamber (2) Make sure that the biochar (6) is in close contact with the outside of the microtube solid oxide fuel cell (3), and cover the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com