Well wall irrigating device and raise boring well wall supporting construction method

A construction method and raise drilling rig technology, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve problems such as difficult safety management and low construction efficiency, and achieve simplification of construction procedures, cost saving, and high economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] To make the object, technical solution and advantages of the present invention more clearly understood, the present invention is further described in detail below by the accompanying drawings. However, it should be understood that the specific examples described herein are only used to explain the present invention and do not limit the scope of the present invention.

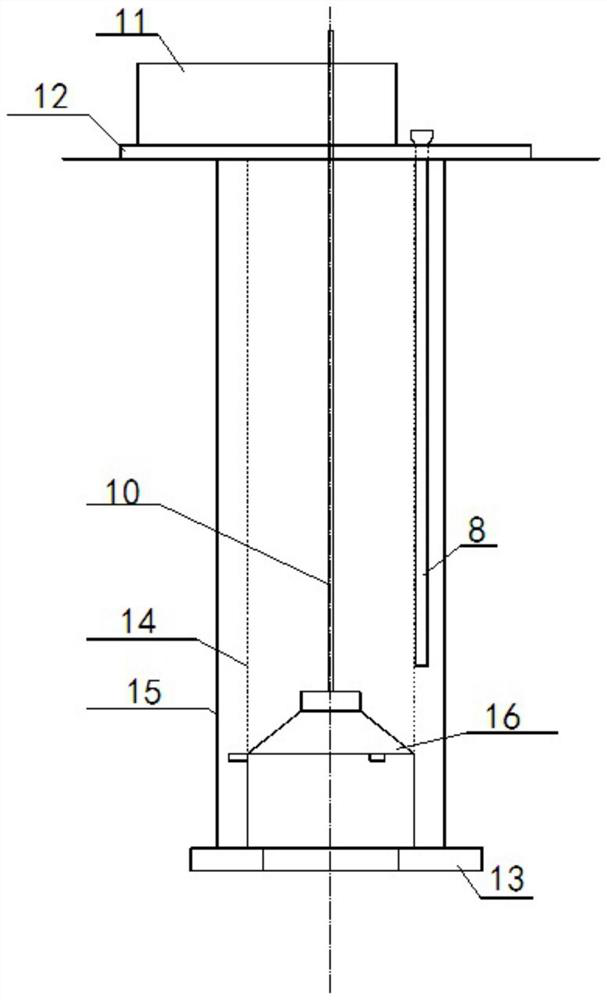

[0033] as Figure 1 As shown, the embodiment design shaft depth of 35m, design diameter of 2800mm, the use of concrete support, the thickness of the well wall 350mm. Reverse drilling is used.

[0034] A kind of reverse well drilling wall support construction method, including the following steps.

[0035] 1) According to the shaft design section, the reverse well drilling rig 11 specifications of the construction shaft are made for the production of well wall pourer 16.

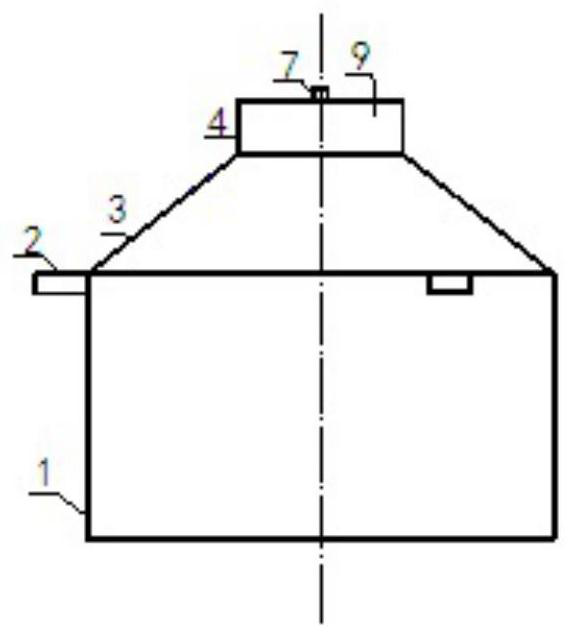

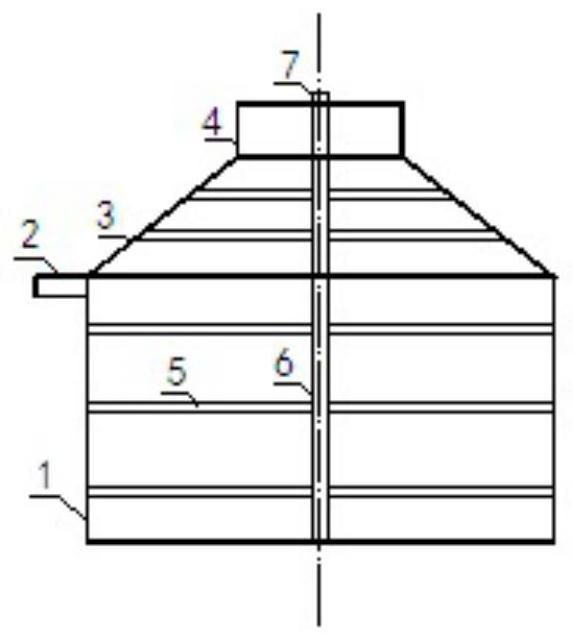

[0036] as Figures 2 through 5As shown, the well wall pourer 16 includes a rotating formwork 1, a leveling mechanism 2, a guide table 3, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com