A wet-type dust-collecting air flow cooling device

A cooling device and air flow technology, applied in the fields of air flow coolers and wet dust-catching air flow cooling devices, can solve the problems of insufficient economic rationality and occupy a large working space, and achieve good dust and dust removal effects, clean air flow and suitable temperature, and enhance dust reduction. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings.

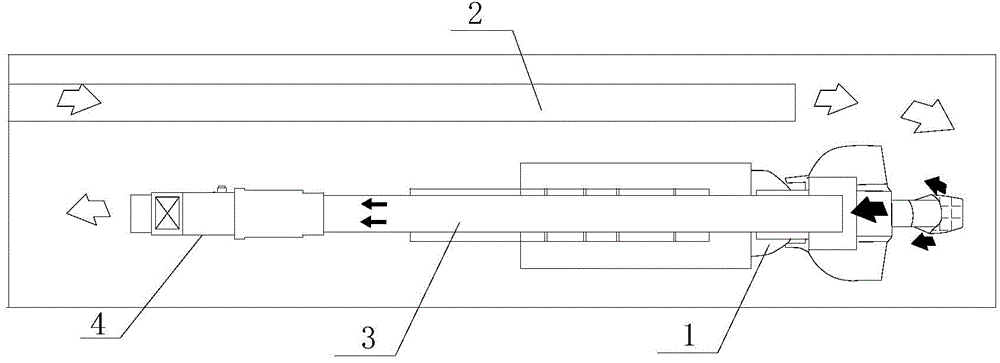

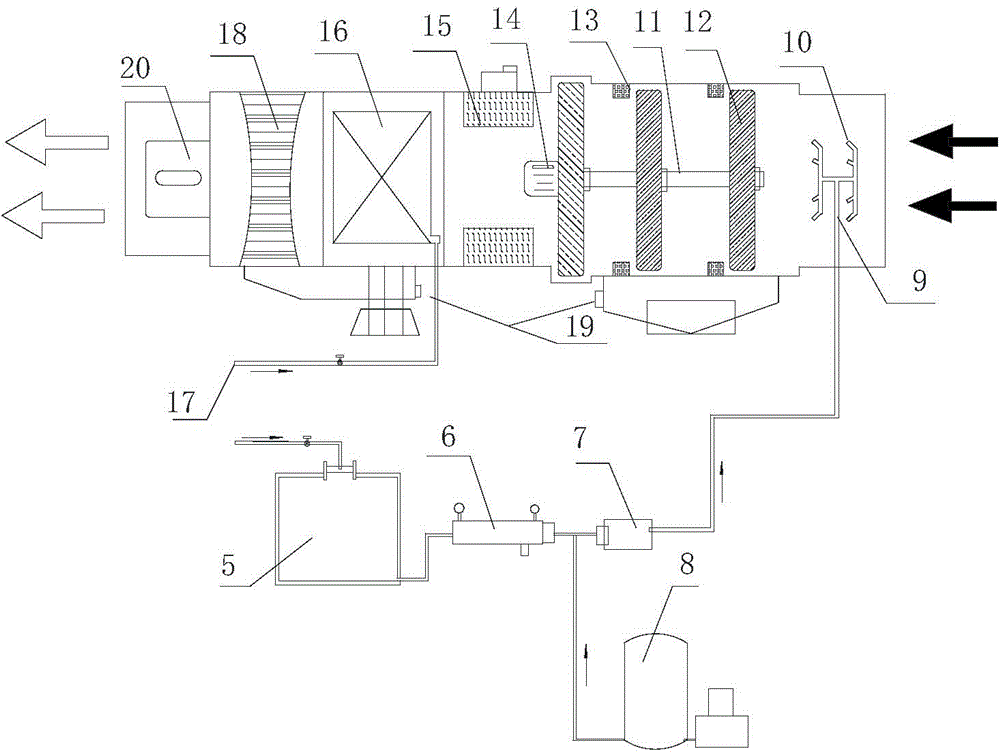

[0051] Such as Figure 1 to Figure 5 As shown, a wet-type dust-collecting wind flow cooling device of the present invention is installed at the head-on rear position of the mining machine 1 on the mining face, and is connected with the outlet end of the dirty air exhaust tube 3, and is characterized in that it includes a casing and the inside of the casing Sequentially connected spray dedusting device 10, cyclone centrifugal dedusting device 11, dust-proof net filter device 15, air-cooled heat exchanger 16, baffle plate demisting device 18; wherein,

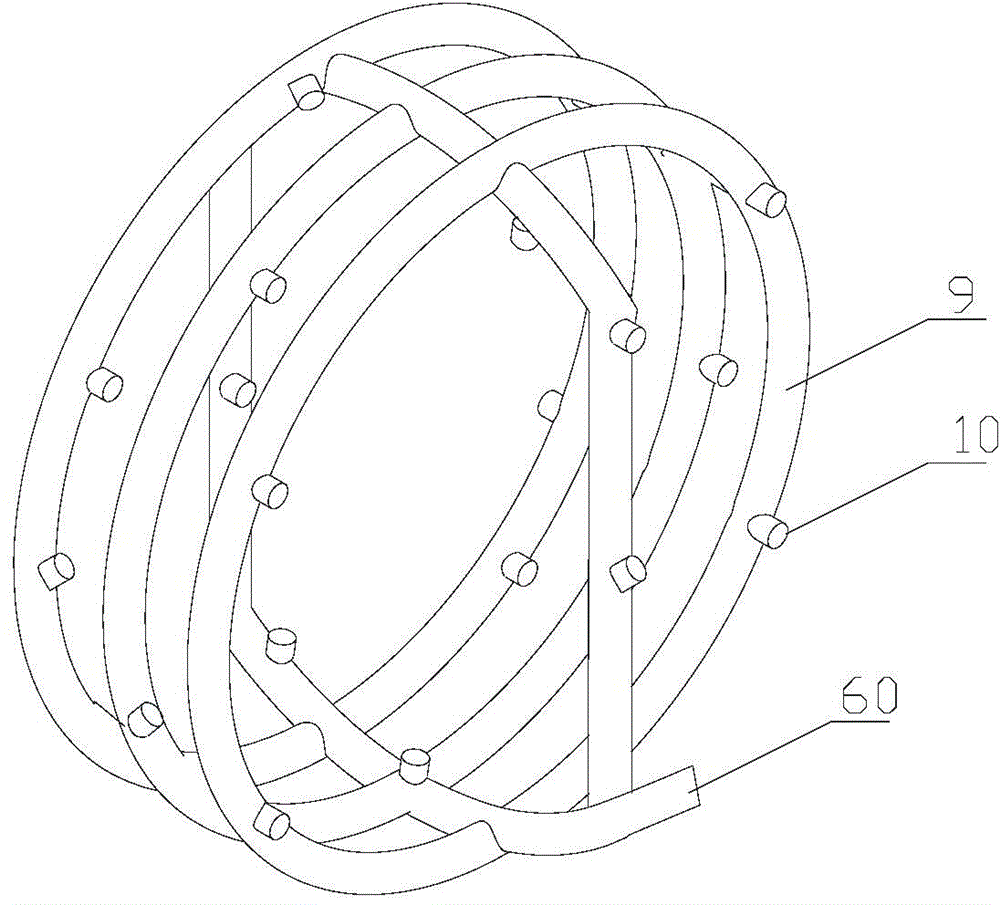

[0052] One end of the inlet pipe 9 of the spray dust removal device 10 is connected to the demister delivery system, and the other end is connected to a helical nozzle support pipe 9 similar to a spring helical structure;

[0053] A certain number of high-pressure atomizing nozzles are evenly arranged on the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com