Trackless equipment central hinge structure with swinging function

A hinged and equipment technology, applied to the substructure, the steering mechanism of the front and rear tandem vehicles, the steering mechanism, etc., can solve the problems of heavy workload and difficult maintenance of the drive axle, so as to reduce the failure rate and increase the effective working time , Ease of maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

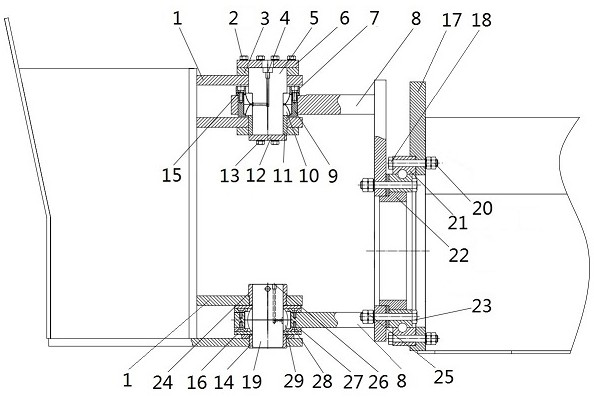

[0010] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

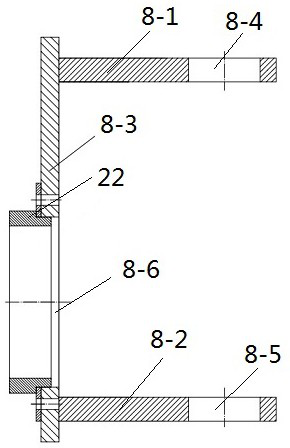

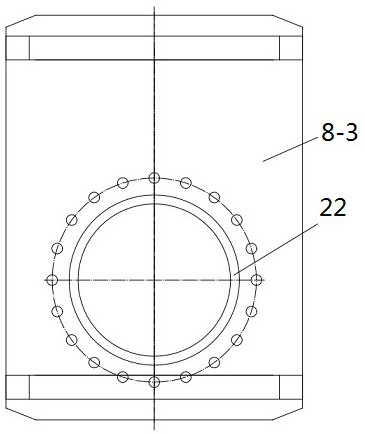

[0011] Such as Figure 1-Figure 3 As shown, a central hinged structure of trackless equipment with a swing function, which includes a front frame, a front frame hinged frame 1 connected to the front frame, a rear frame, and a rear frame hinged frame 17 connected to the rear frame , Swing frame 8. The swing frame 8 is an important structural part that realizes the rotation and swing between the front frame hinge frame 1 and the rear frame hinge frame 17. It consists of a horizontal upper swing plate 8-1, a horizontal lower swing plate 8-2, a vertical The side swing plates 8-3 in the vertical direction are connected and formed in an L shape. The upper swing plate 8-1 is provided with an upper hinge hole 8-4, and the lower swing plate 8-2 is provided with a lower hinge hole 8-5. The hole 8-4 is concentric with the lower hinge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com