Shock insulation support with vibration liquefied material

A vibration liquefaction and seismic isolation bearing technology, applied in earthquake prevention, building types, buildings, etc., can solve the problems of engineering structure disasters and aggravation, and achieve the effect of obvious isolation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation modes in conjunction with the accompanying drawings.

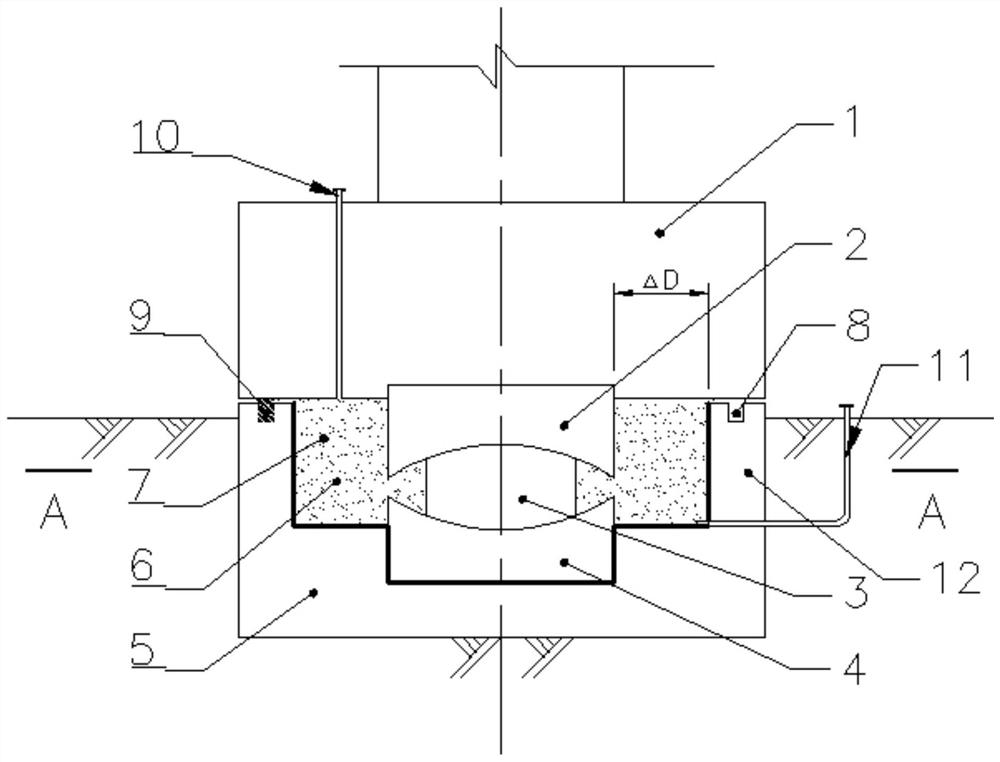

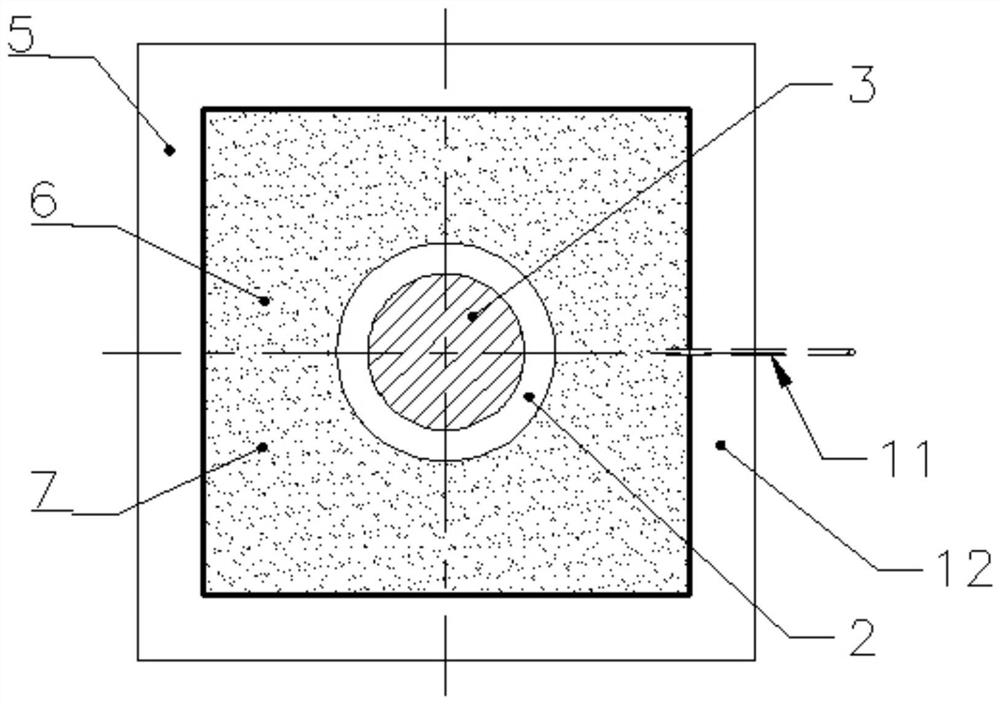

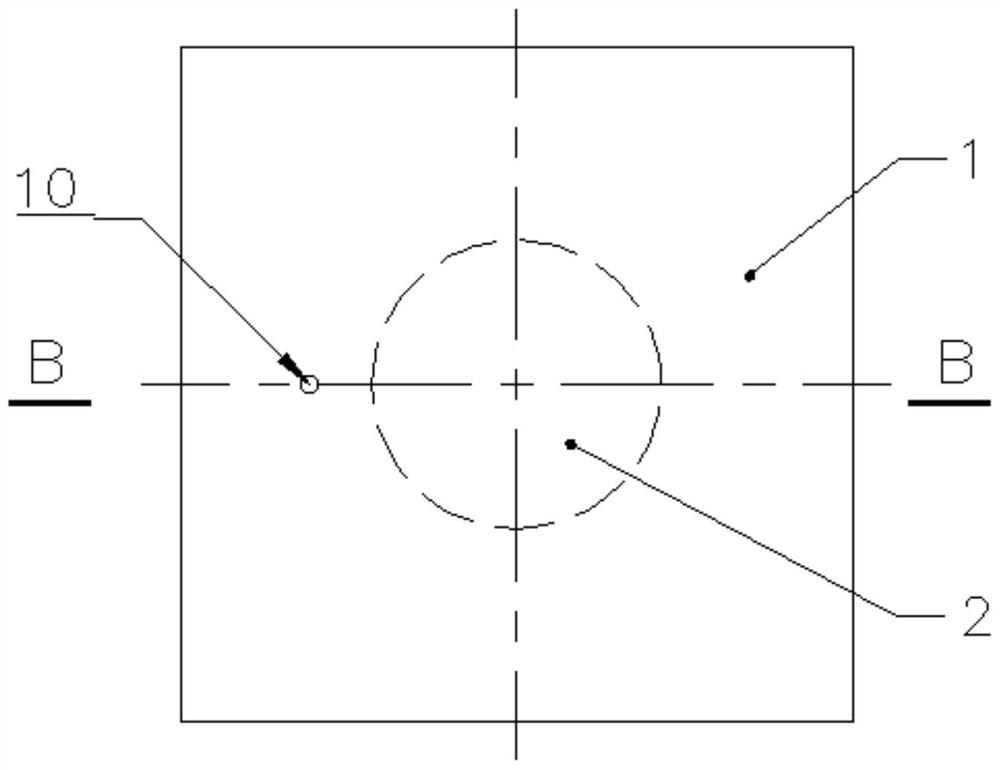

[0028] as attached figure 1 , a shock-isolation support with vibrating liquefied material, including a cover plate 1, an upper pier 2, a sliding block 3, a lower pier 4, a foundation 5, a holding tank 6, a vibrating liquefied material 7, a sealing strip 8, and a sealing groove 9. Exhaust pipe 10, infusion pipe 11, pool wall 12; the top surface of the cover plate 1 is an engineering component to be isolated; the outer contour size of the bottom surface of the cover plate 1 is not smaller than the outer contour size of the top surface of the pool wall 12; the upper pier 2 The top surface is fixed on the bottom surface of the cover plate 1, and the bottom surface of the upper pier 2 is an upward concave spherical sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com