Pipe piece conveying device suitable for large-gradient transportation of whole-ring pipe pieces and conveying method of pipe piece conveying device

A conveying device and a large-slope technology, which is used in vertical shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problem of not being able to meet the large-slope transportation of the whole ring segment at the same time, and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

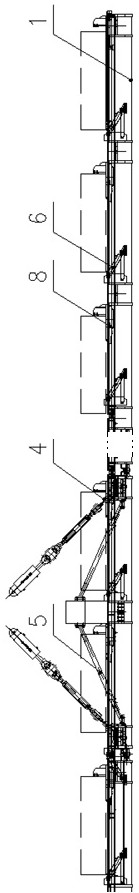

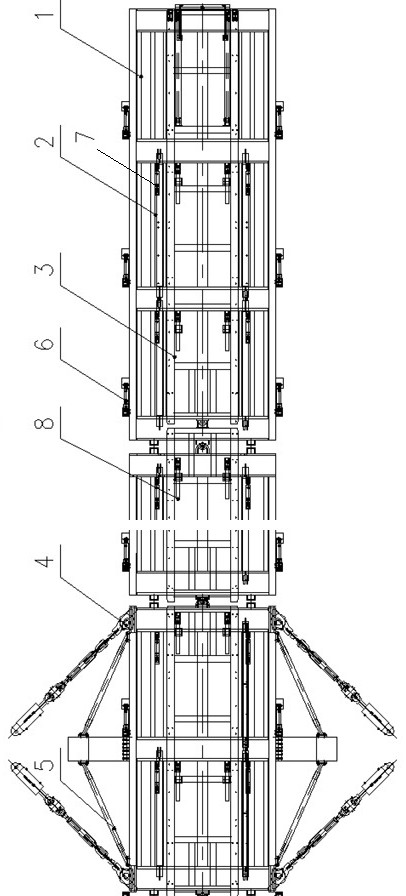

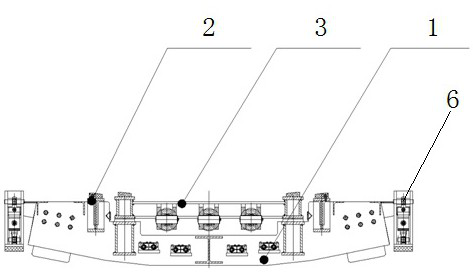

[0042] Embodiment 1, a segment conveying device adapted to the large-slope transportation of the entire ring segment, such as Figure 1-Figure 3 As shown, it includes an underframe 1 connected to the trailer or the main engine of the boring machine, and the underframe 1 is connected to the trailer or the main engine through the first pulling structure 4 or / and the second pulling structure 5, and the first pulling structure 4 is an existing The dragging structure commonly used in the technology, the second dragging structure 5 includes a screw structure, and its length is adjustable. The underframe 1 includes several connected frames, each frame can be rigidly connected or flexibly connected or hinged, and when flexible connection or handover is adopted, it is convenient to follow the trailer or the main engine to realize steering.

[0043] Several stepping units are sequentially arranged on the underframe 1, each stepping unit includes a lifting frame 2 and a sliding frame 3, ...

Embodiment 2

[0058] Embodiment 2, the conveying method of the segment conveying device adapted to the large-slope transportation of the entire ring segment, such as Figure 11 As shown, when excavating in a normal tunnel section or a section with a small slope, the overall hoisting mechanism 6 retracts, the trailer or the main engine pulls the underframe 1 through the first pulling structure 4, and the segment conveying device travels on the assembled segment, the first The drag structure 4 normally adjusts the position of the underframe 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com