A voltage stabilizer for engine cooling system

A technology of engine cooling and voltage stabilizing device, which is applied in the direction of engine cooling, engine components, machines/engines, etc. It can solve the problems of inconvenience, poor flexibility, inaccurate coolant pressure, etc., and achieve ingenious design and increased sealing , the effect of precise accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

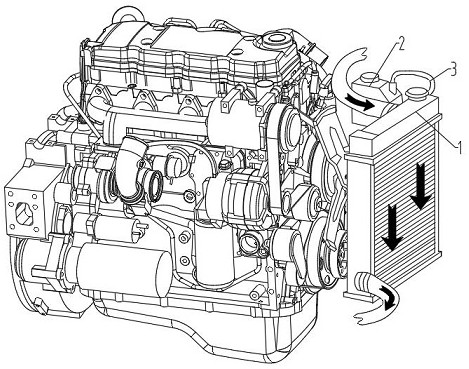

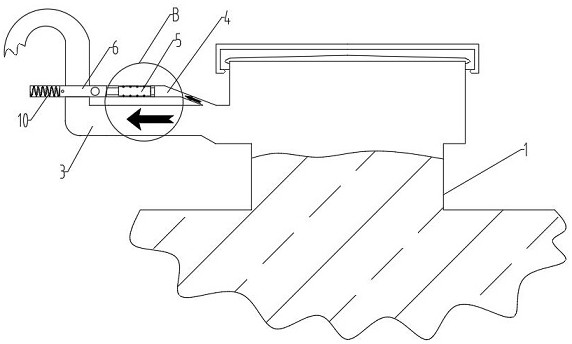

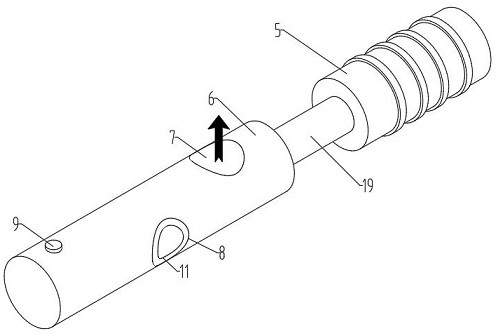

[0033] Example: as Figure 1-10 As shown, a voltage stabilizer for an engine cooling system includes an engine water-cooling circulation pipeline, a heat sink, and a main water tank 1. The top of the main water tank 1 is connected to an auxiliary water tank 2 through a pressure relief pipe 3. The pressure relief The side of the pipe 3 close to the main water tank 1 is provided with a pressure pipe 4 that communicates with it. The pressure pipe 4 is provided with a control component for controlling the internal pressure value of the main water tank 1; the control component includes a coaxial and sliding A pressure relief rod sealed inside the pressure pipe 4, the front section of the pressure relief rod is a sliding head 5 that matches the inner wall of the pressure pipe 4, and a plurality of sealing rings to enhance sealing are sleeved on the sliding head 5; The rear section of the pressure relief rod is a cylindrical control part 6 arranged coaxially with the sliding head 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com