Single-person ground potential live-line defect elimination method for high-voltage connector heating defect

A technology of high-voltage joints and ground potential, which is applied in the direction of wire-wound connectors, electrical connection seats, fastening/insulation connectors, etc., can solve problems such as insufficient contact, limited compression of damping springs, and difficult installation, etc., to achieve extended use The effect of life, avoiding the difficulty of matching, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

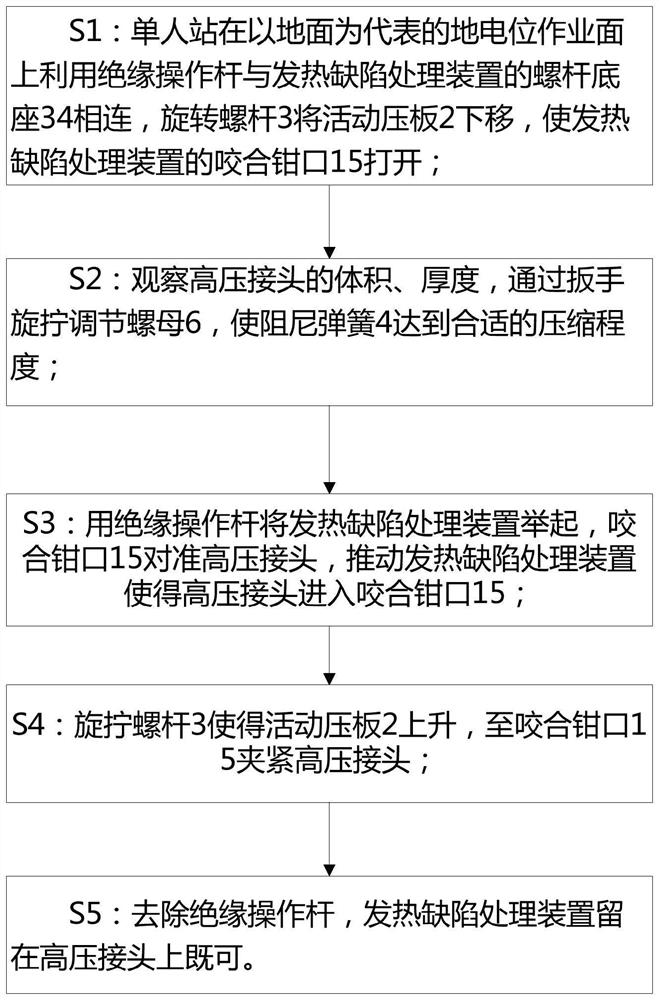

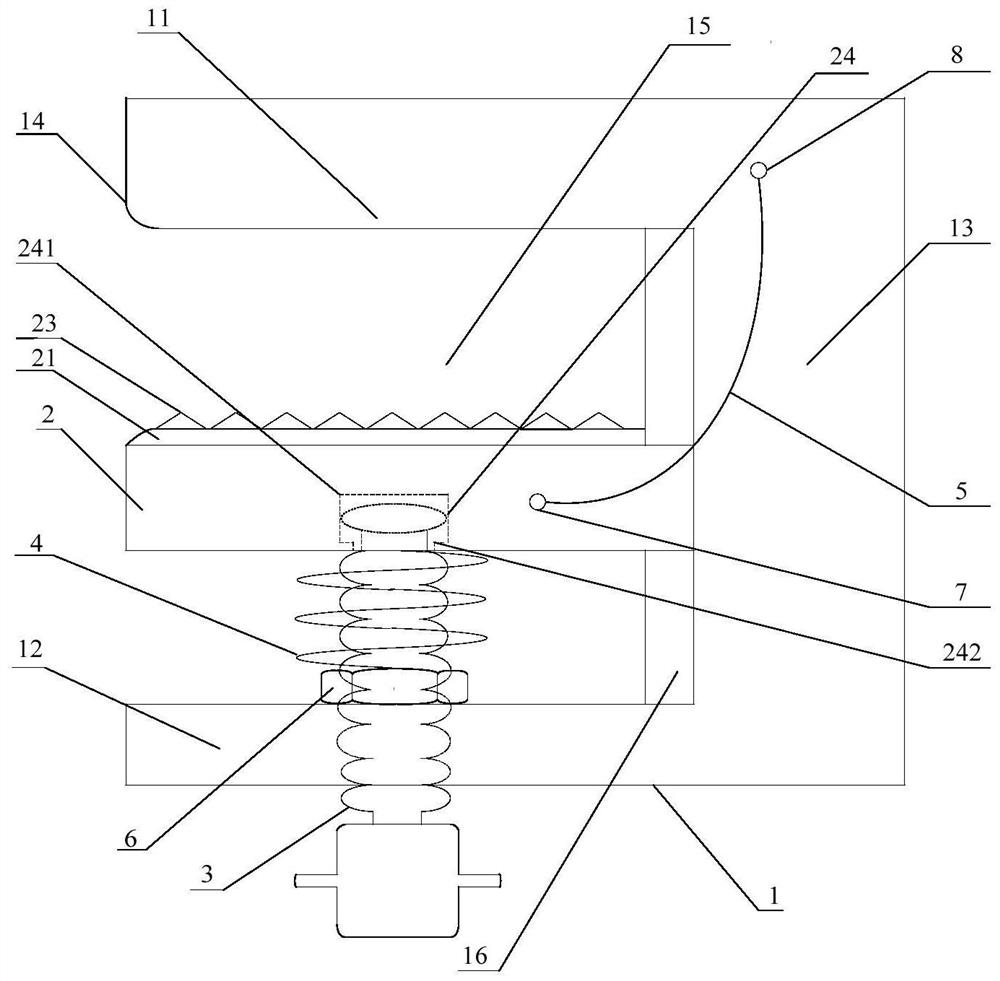

[0035] see Figure 1-5 : A single-person ground potential charged defect elimination method for heating defects of high-voltage joints. When current-type heating defects are found to occur in high-voltage joints, the processing method is:

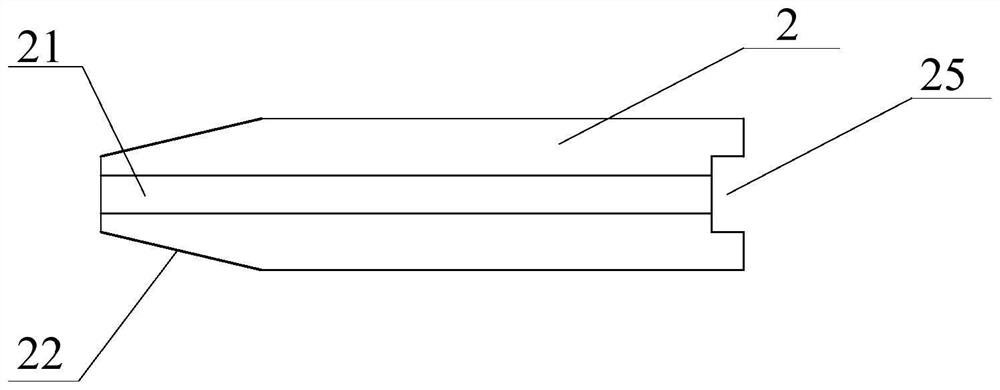

[0036] S1: A single person stands on the ground potential work surface represented by the ground and connects the screw base 34 of the heating defect treatment device with an insulating operating rod, and rotates the screw 3 to move the movable pressing plate 2 downwards, so that the occlusal jaws of the heating defect treatment device 15 open;

[0037] S2: Observe the volume and thickness of the high-pressure joint, and screw the adjusting nut 6 with a wrench to make the damping spring 4 reach a suitable compression level;

[0038] S3: Lift the heating defect treatment device with the insulating operating rod, align the bite jaw 15 with the high-voltage joint, and push the heat generation defect treatment device so that the high-voltage j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com