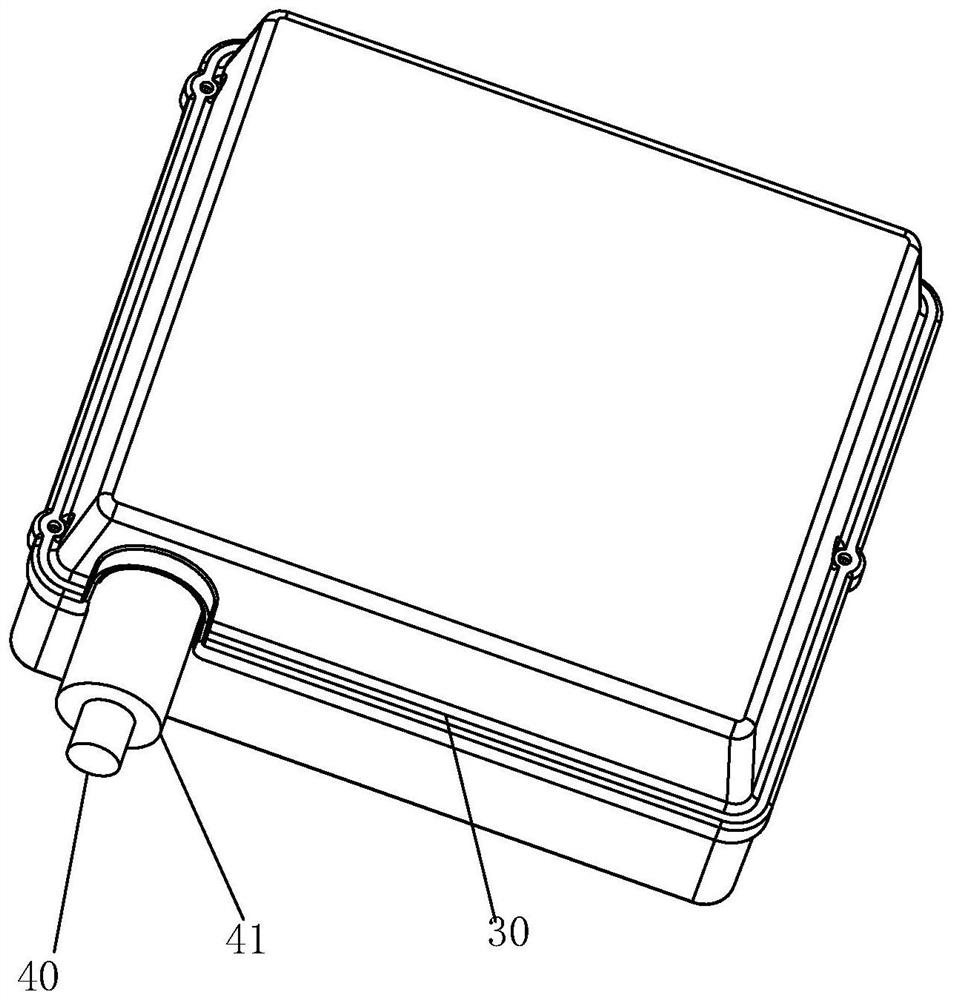

Anti-condensation electronic device and method

An electronic device and anti-condensation technology, which is applied in the field of forklifts, can solve the problems of inability to solve the problem of condensed water in connectors and high cost, and achieve the effects of avoiding EMC problems, low cost, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

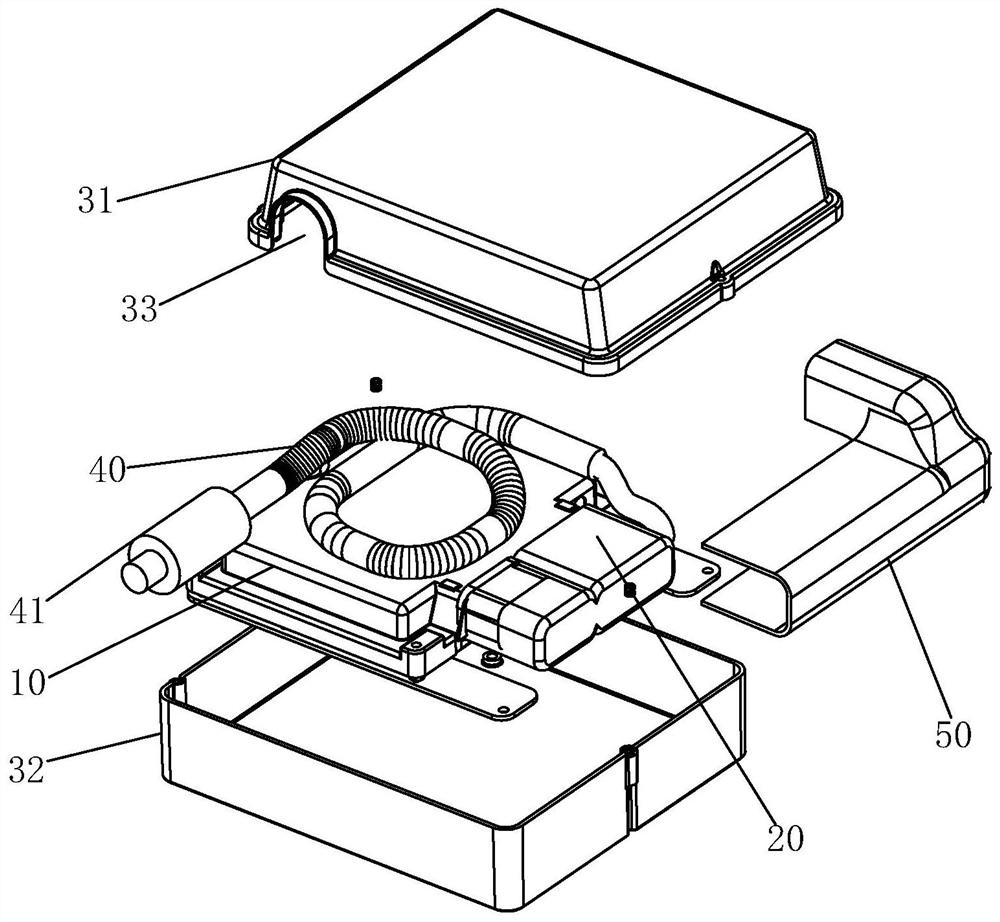

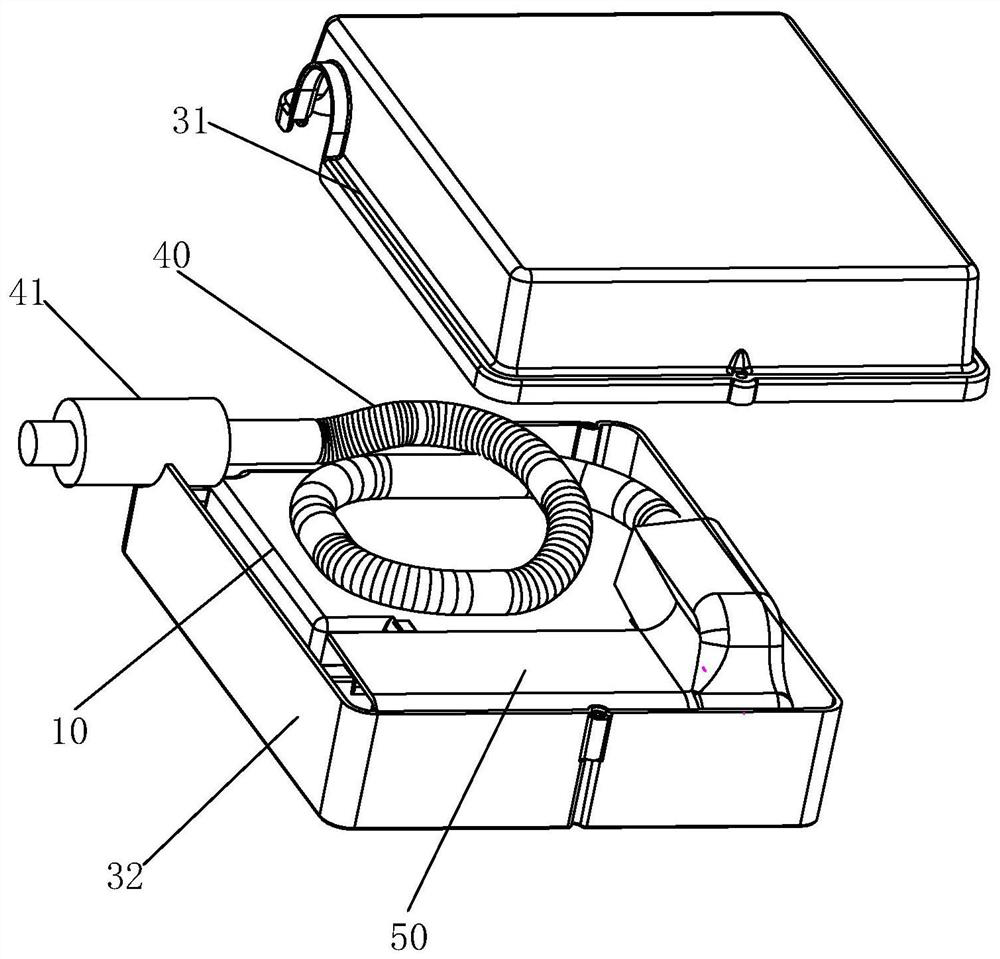

[0050] An anti-condensation electronic device and method, the main features of which are the same as those of the first embodiment, the difference is that the heating element 50 completely wraps the built-in wire harness 40 in addition to the connector 20 . Specifically, two heating elements 50 may be included, one heating element 50 wraps the built-in wire harness 40 , and the other heating element 50 wraps the connector 20 . Alternatively, a heating element 50 can also be set to wrap the built-in wire harness 40 and the connector 20 at the same time, which can be selected according to actual conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com