Light press type operation tool storage platform capable of preventing instantaneous impact

An operating tool, pressing technology, applied in the direction of manufacturing tools, claw arms, manipulators, etc., can solve the problems of poor resistance to impact load of the cover, small pressing moment of the cover, and low rigidity of the opening and closing mechanism, etc., to improve passive resistance. Impact capability, large reduction ratio, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other without conflict, and the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

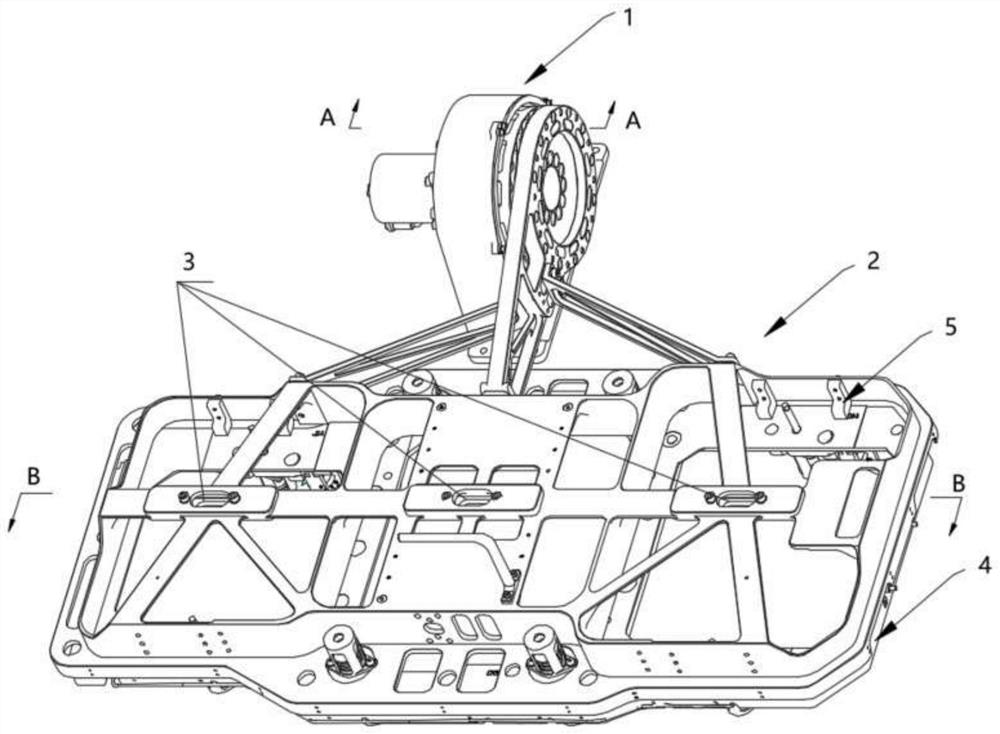

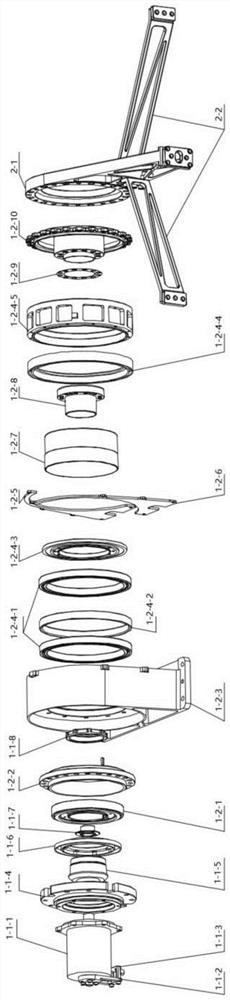

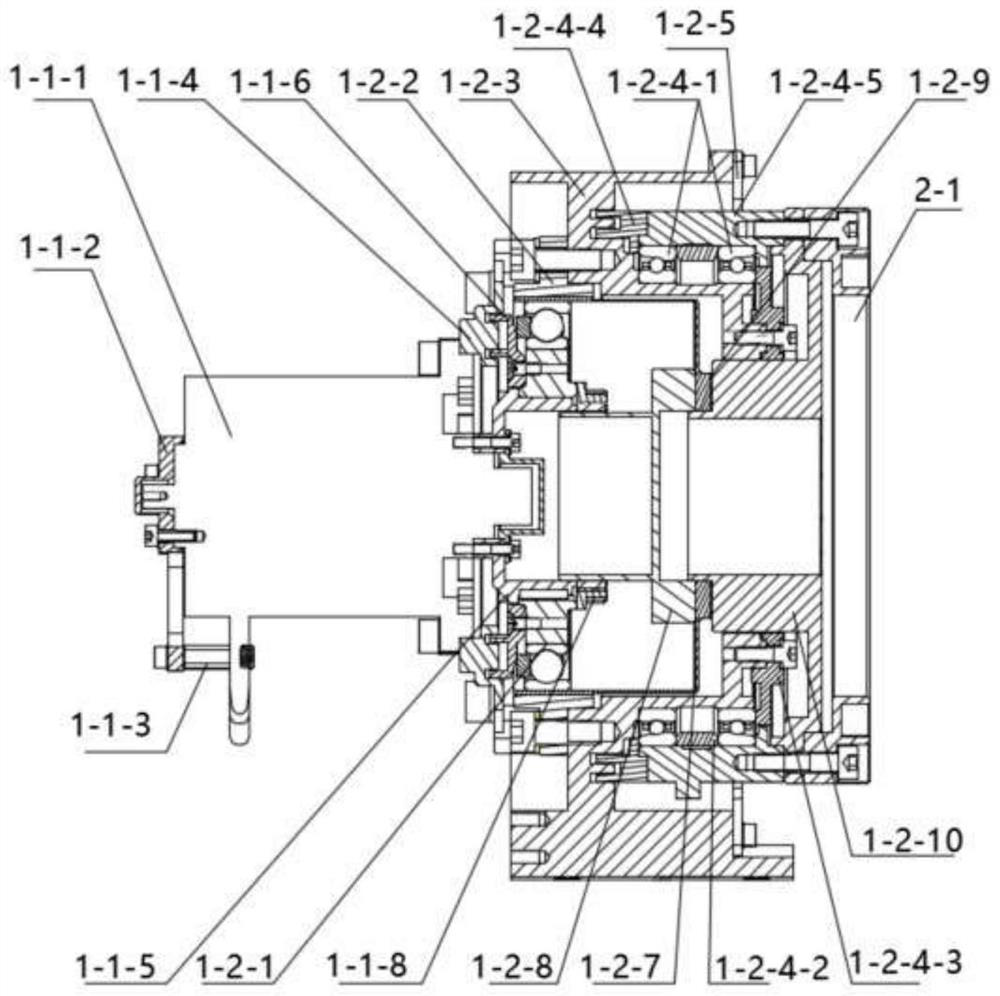

[0039] like Figure 1-Figure 6 As shown, a light-weight press-type operation tool storage platform with anti-instantaneous impact includes an opening and closing drive mechanism 1, a tripod-type impact-resistant cover plate mechanism 2, a tool bracket 4 and a spring buffer mechanism 3;

[0040] The triangular bracket type shock-proof cover plate mechanism 2 includes a main bracket 2-1, two auxiliary brackets 2-2 and a cover plate 2-3. The auxiliary brackets 2-2 and the main bracket 2-1 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com