Small-size high-speed carton printer

A small size, printer technology, applied in printing devices, printing, etc., can solve the problems of not having cleaning and moisturizing functions, affecting the normal use of printers, increasing production costs, etc., to achieve the effects of avoiding blockage, facilitating transportation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

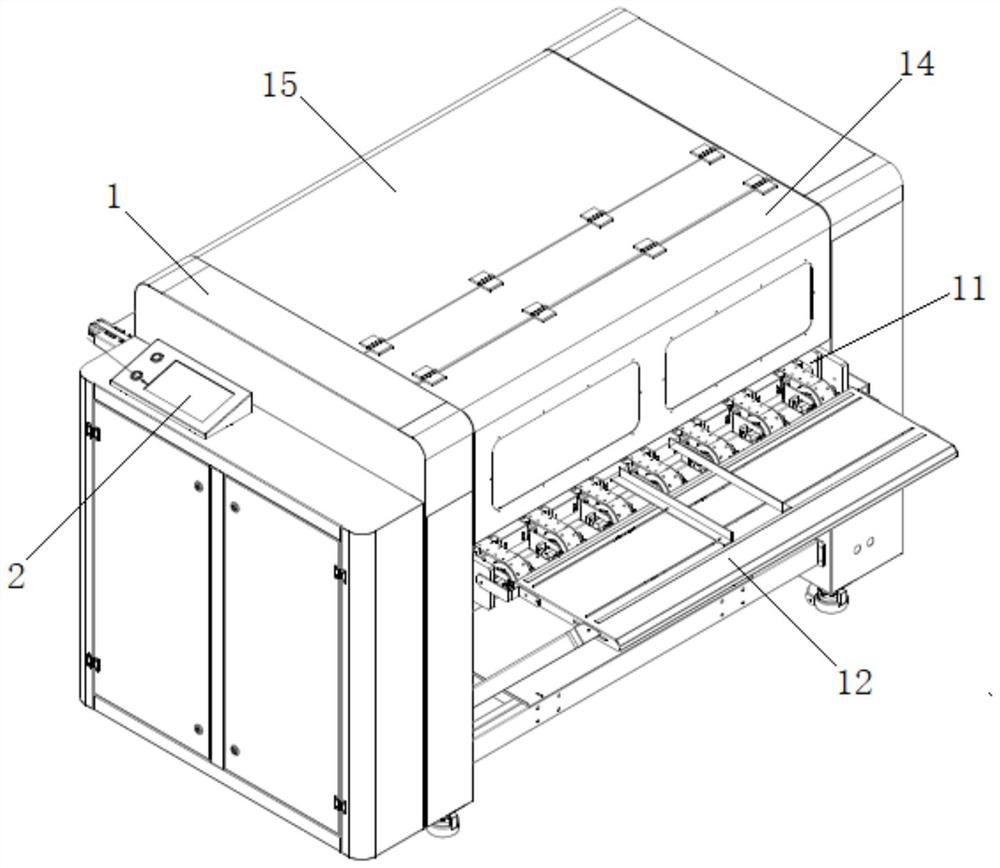

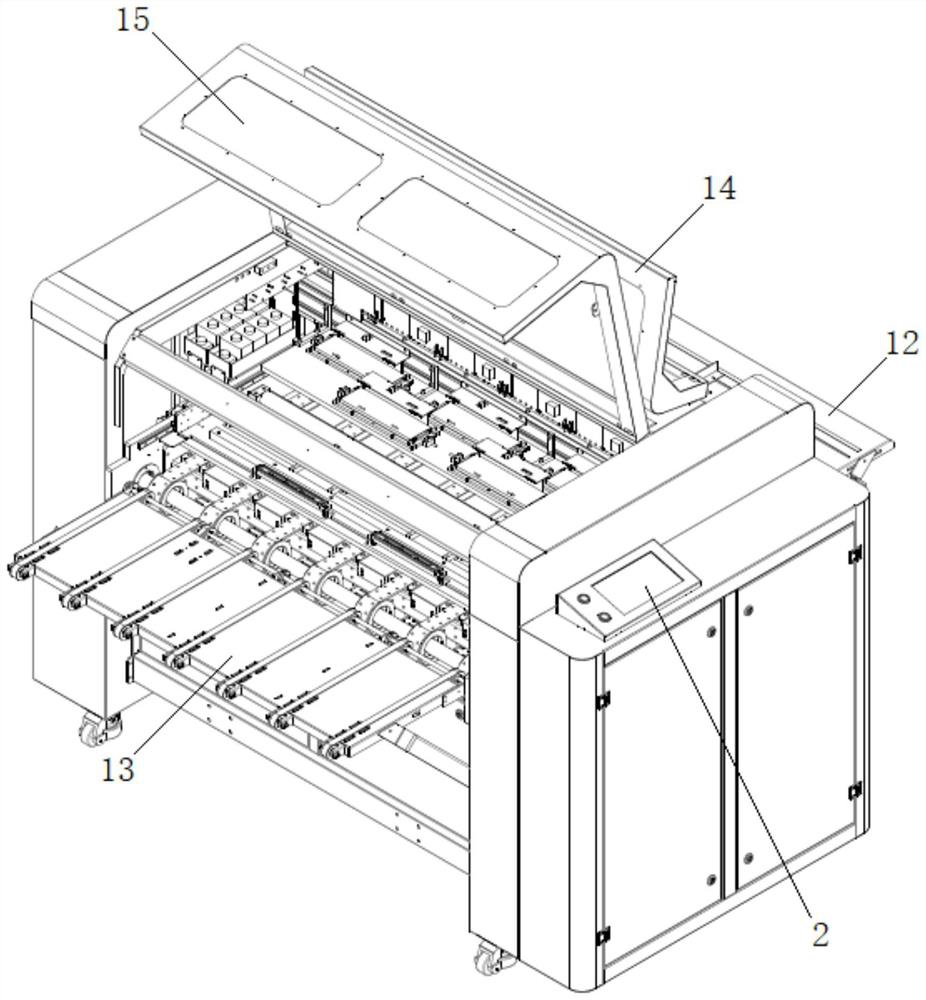

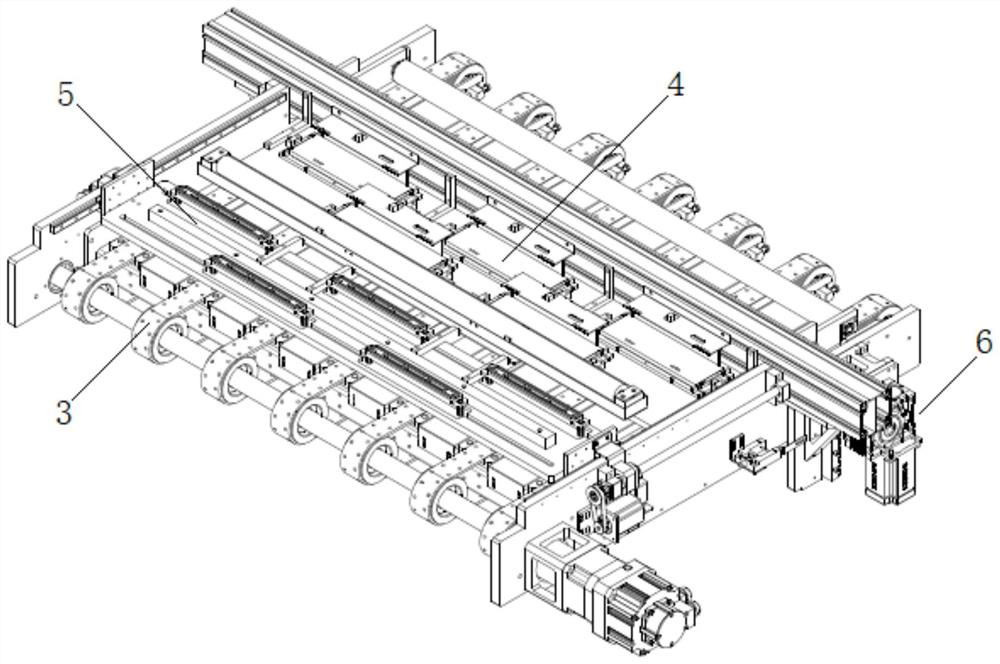

[0030] attached Figure 1-6 It is a small-sized high-speed carton printer according to the present invention, comprising a chassis 1, a suction conveying platform 3 horizontally arranged in the chassis 1 and conveyed in the front-rear direction, and a printing device respectively disposed in the chassis 1 and located above the suction conveying platform 3. Mechanism 4 and cleaning and moisturizing mechanism 5, a height adjustment mechanism 6 arranged in the casing 1 for driving the printing mechanism 4 to rise and fall, an ink supply mechanism 7 arranged in the casing 1 for supplying ink to the printing mechanism 4, arranged outside the casing 1 The operating table 2 at one end; the operating table 2 is used to control the action of the suction transmission platform 3, the printing mechanism 4, the cleaning and moisturizing mechanism 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com