Detection line for ferrite magnetic shoe passing through go gauge

A technology of ferrite magnetism and detection lines, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of magnetic tile over-gauge failure, misjudgment, and detection line stuck quality, etc., to achieve smooth operation rhythm and technical Reliable solutions and the effect of enhancing product value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the absence of conflict, the embodiments in the present application and the features in the embodiments may be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with an embodiment.

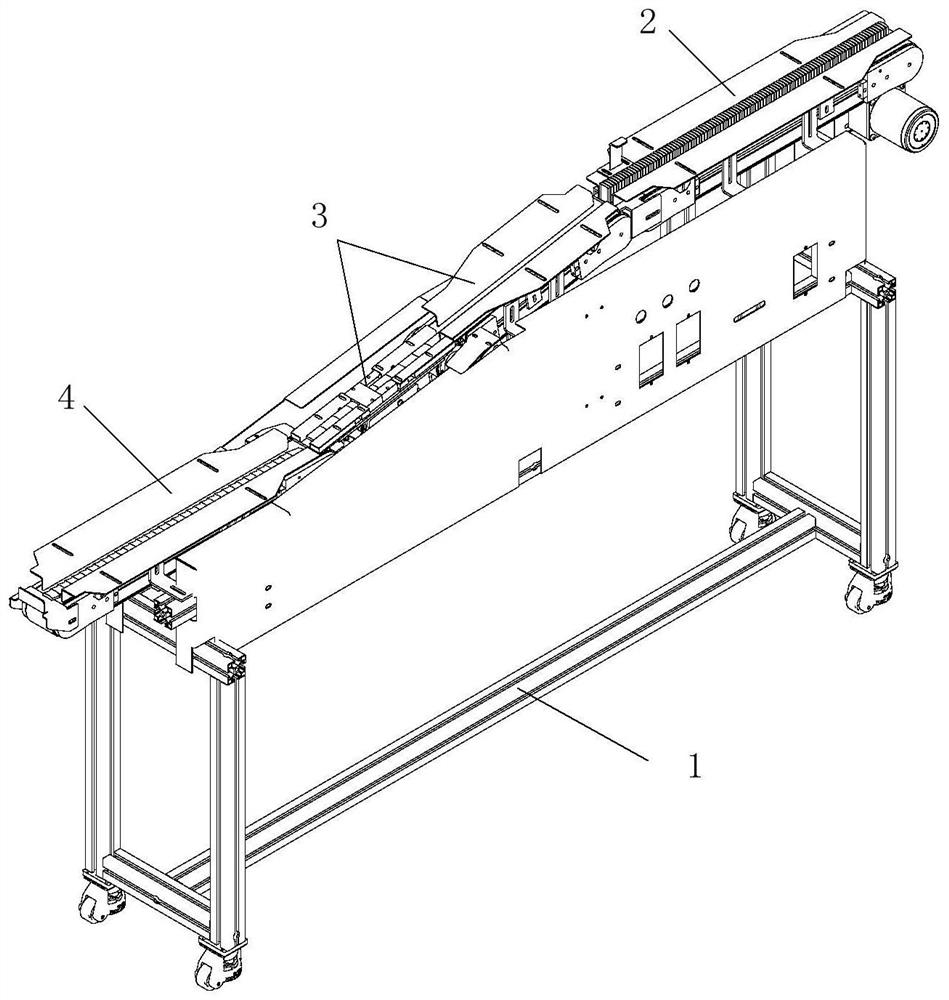

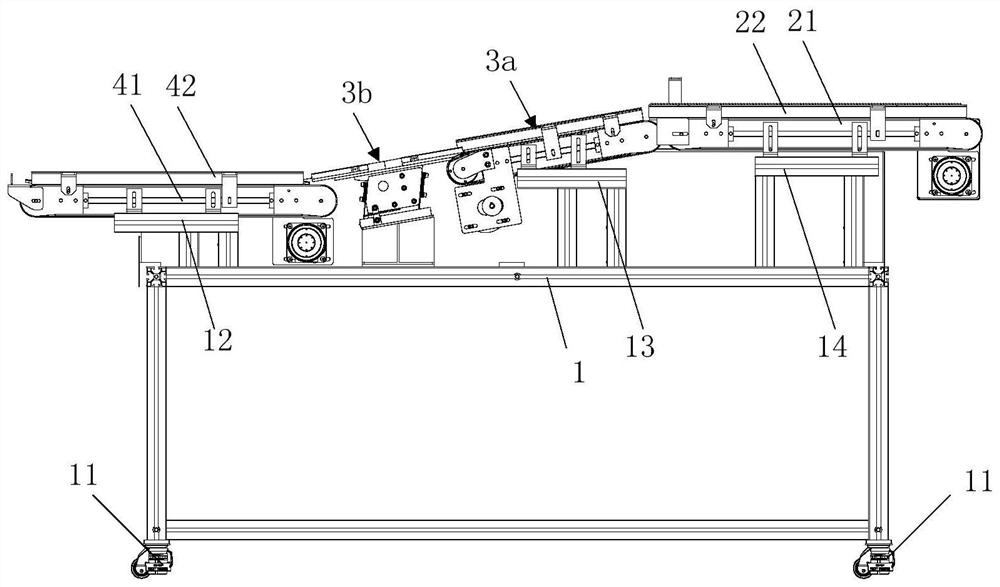

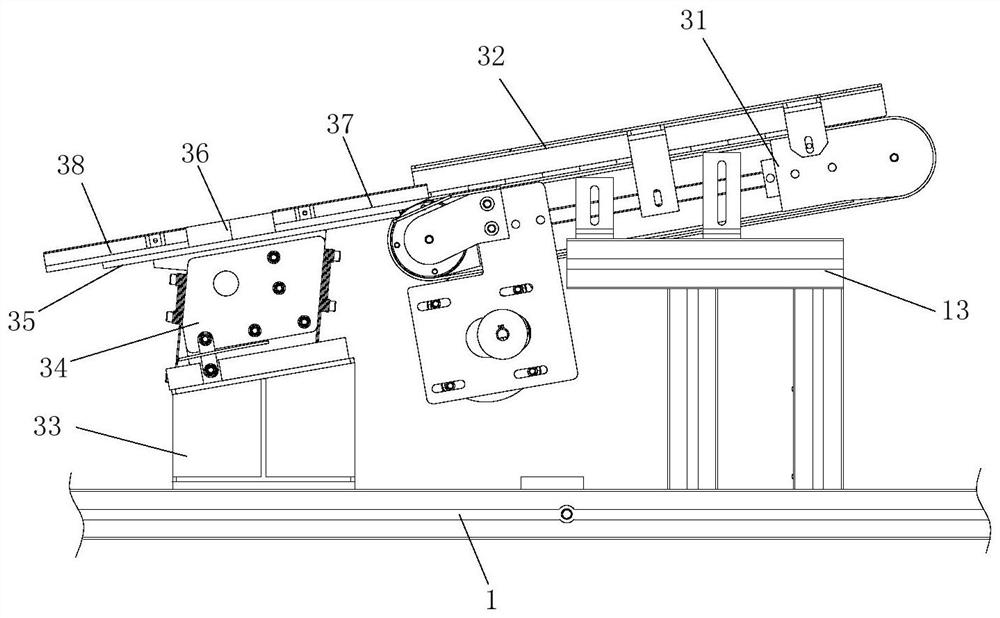

[0023] Combine references Figures 1 to 4 , the ferrite magnetic tile pass gauge detection line of the present invention comprises a rack 1, a magnetic pad feeding device 2, a pass gauge device 3, and a magnetic pad receiving device 4.

[0024] Rack 1 is an aluminum profile frame construction with horizontally adjustable castors 11 mounted at all four corners, such as the GD-40F, capable of moving position and leveling. There are also three aluminum profile structural brackets 12, 13 and 14 on rack 1.

[0025] The magnetic tile feeding device 2 is supported on the frame 1, consisting of a first belt conveyor 21, a magnetic tile groove 22 disposed on its conveyor surface, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com