Device for testing bonding strength of organic glass in casting molding and use method

A technology of plexiglass and bonding strength, which is applied in the direction of measuring devices, mechanical devices, and preparation of test samples. It can solve problems such as difficult clamping, easy breakage, and difficult to complete the measurement of mechanical parameters, and achieves the demoulding process. Stable, data-reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, the described embodiments are a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0028] In addition, the technical features involved in the different embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

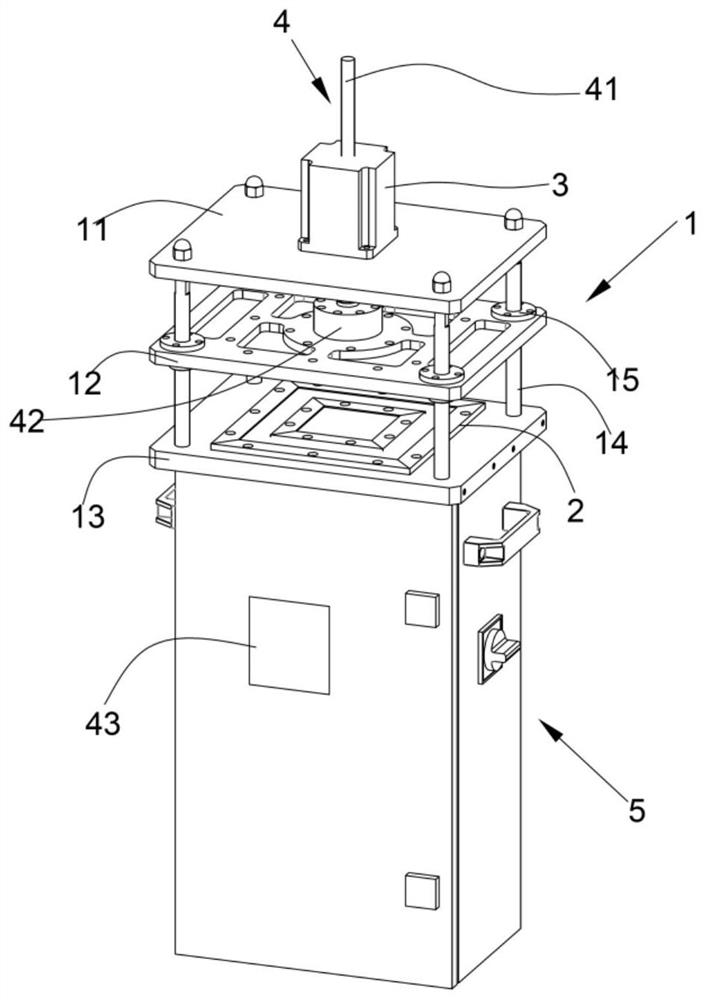

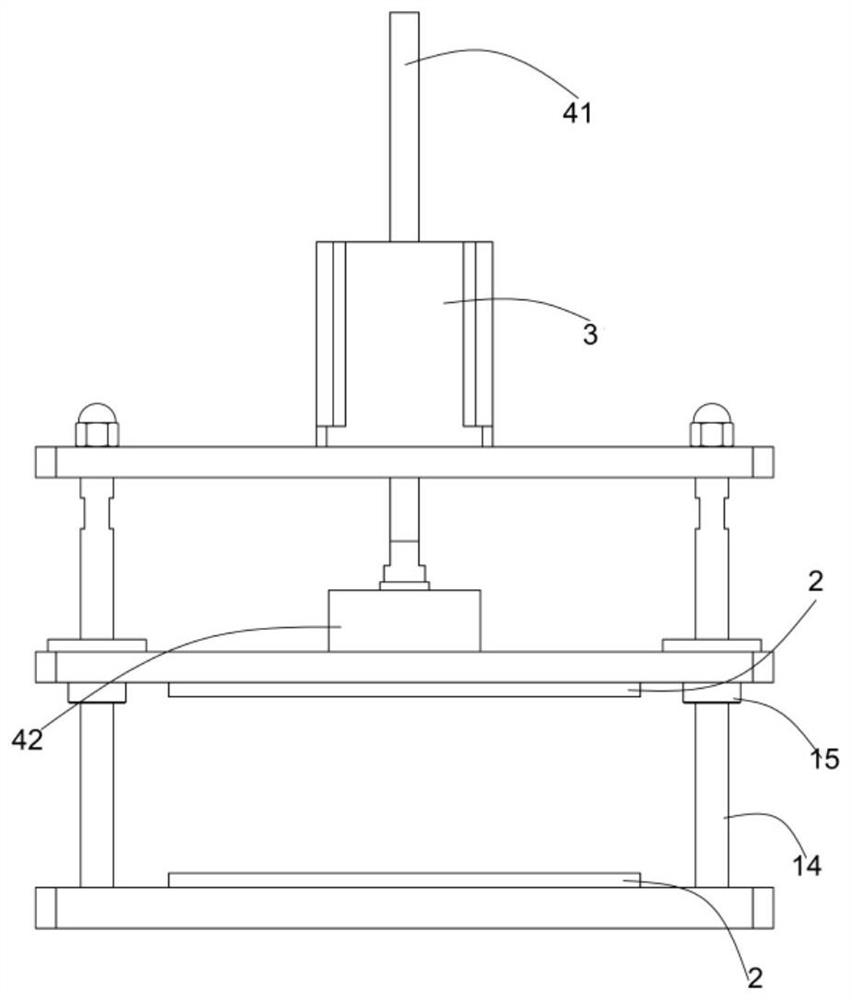

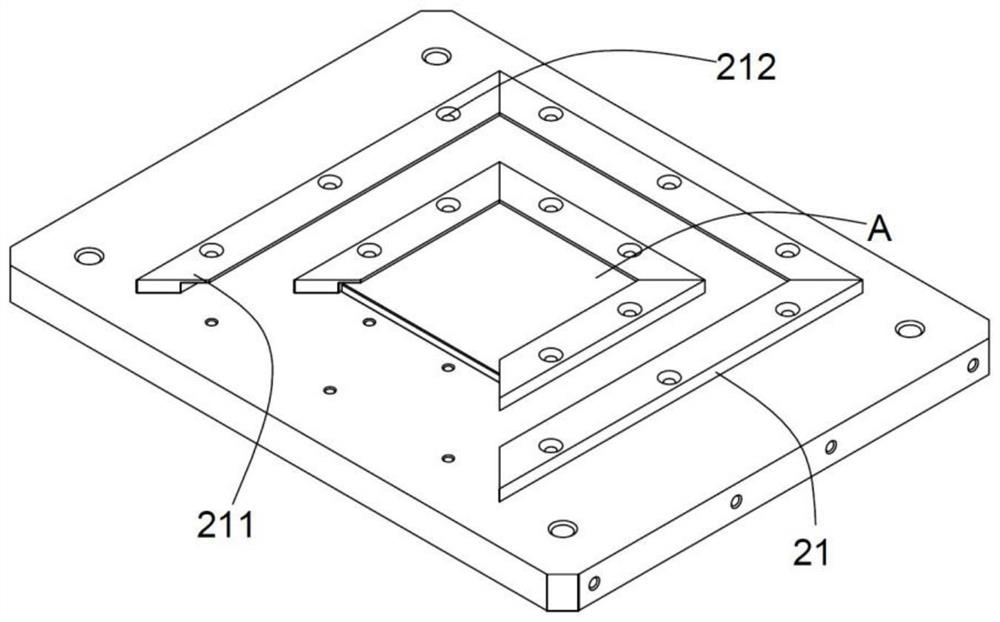

[0029] like Figure 1-3 As shown, the present case provides a device for testing the bonding strength of cast-molded plexiglass, comprising:

[0030] Bearing platform 1, the bearing platform includes an upper fixed platform 11, a middle movable platform 12 and a lower fixed platform 13, and the lowe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap