Ultrasonic detection method for micro-nano cracks of metal material

A metal material and ultrasonic testing technology, which is applied in the direction of analyzing solids with sound waves/ultrasonic waves/infrasonic waves, analyzing materials, and using sound waves/ultrasonic waves/infrasonic waves for material analysis. Missed detection, false detection and other problems, to achieve the effect of filling technical and theoretical gaps, improving detection efficiency and accuracy, and breaking through application bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will now be further described with reference to the accompanying drawings.

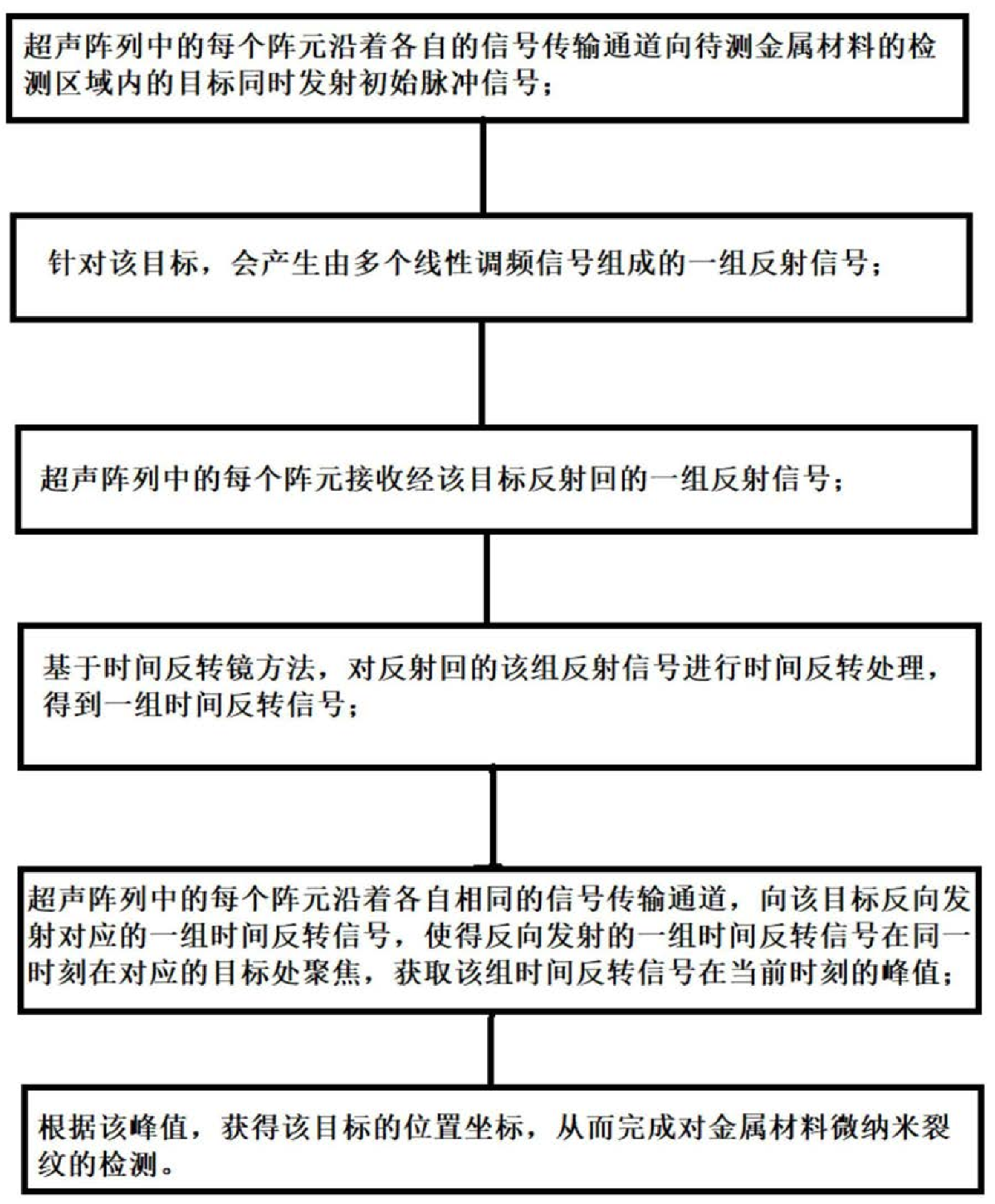

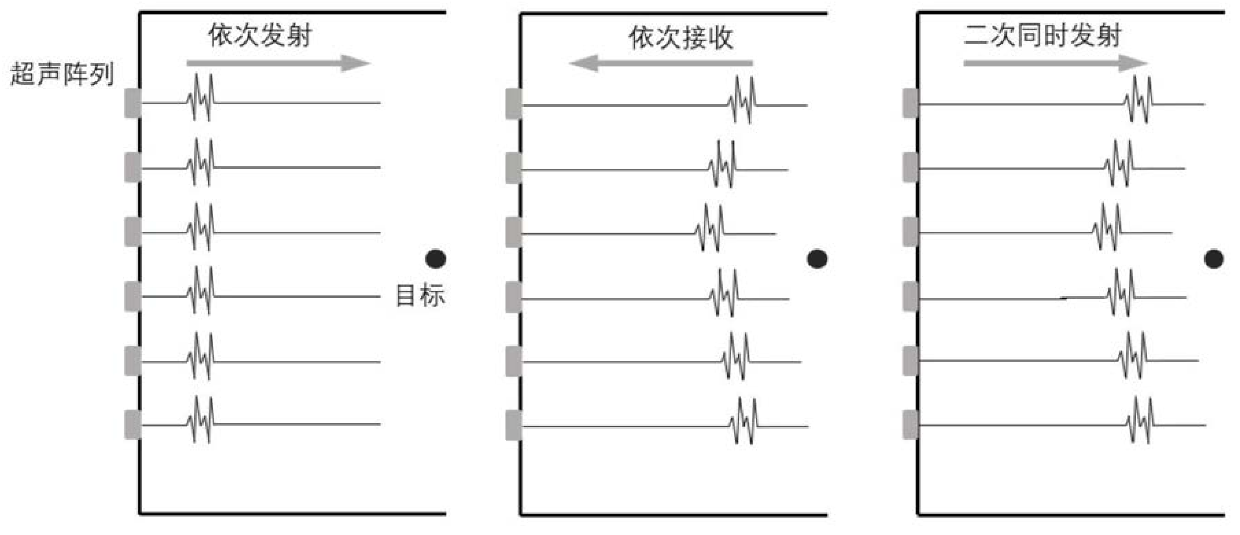

[0055] The invention provides an ultrasonic detection method for micro-nano cracks in metal materials. The method uses a time-reversing mirror method (Time-Reversing Mirror) combined with a linear frequency modulation signal, and does not require prior knowledge to perform adaptive focusing on sound waves , to achieve the adaptive focusing of sound waves in non-uniform media, that is, using the linear frequency modulation signal as the excitation signal, and using the time-reversal mirror technology to realize the adaptive focusing of the sound waves, so as to complete the accurate detection of micro-nano cracks in metal materials.

[0056] like figure 1 As shown, the method includes:

[0057] Each array element in the ultrasonic array simultaneously transmits an initial pulse signal to the target in the detection area of the metal material to be tested along its respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com