Equipment and method for preparing organic glass with high heat resistance

A plexiglass, heat-resistant technology, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of difficult distance control, difficult to keep the finished product size accurate and uniform, adhered to the interior of the interlayer, etc. problem, to achieve the effect of easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

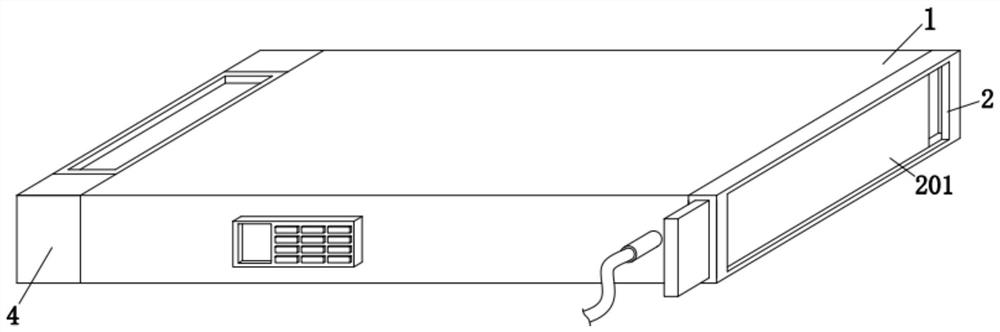

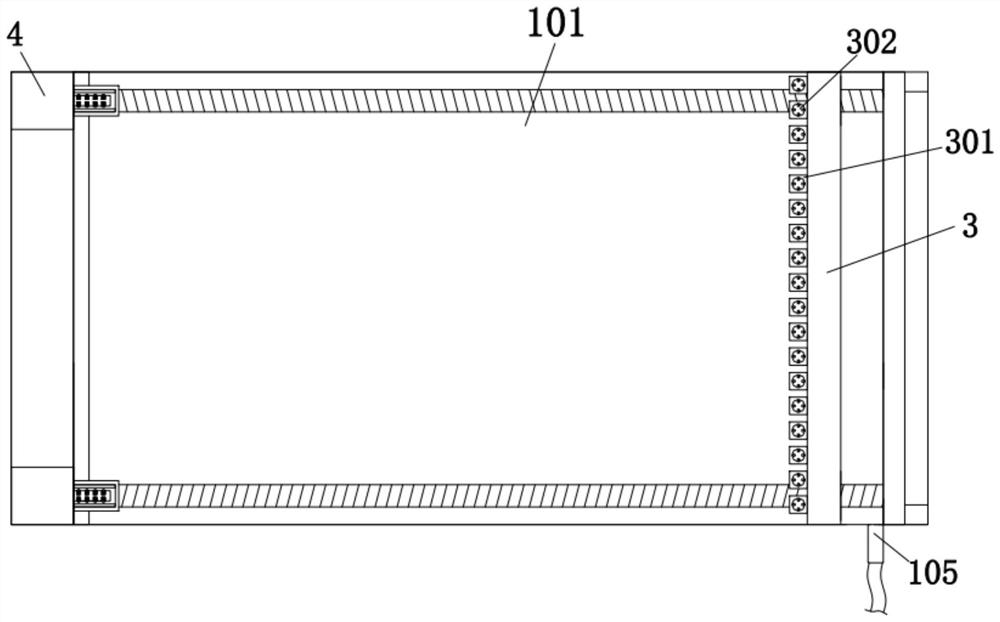

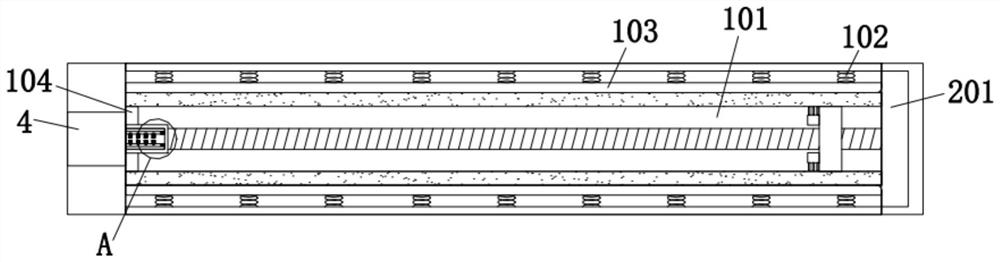

[0057] see Figure 1-8 middle,

[0058] A plexiglass preparation device with high heat resistance provided in this embodiment includes: a main body 1, a processing bin 101 opened inside the main body 1, which is convenient to provide a processing space for the acrylic plate 6, and is opened on one side of the main body 1 for use The liquid injection port 104 for injecting the liquid polysulfone material between the two acrylic plates 6 is arranged inside the processing chamber 101 for automatically pushing the processed plexiglass out of the push plate 3 of the main body 1, and is arranged inside the processing chamber 101 for use. For the clamping component for engaging the acrylic plate 6 , the driving component disposed inside the processing chamber 101 for pushing the push plate 3 to move, and the cleaning component disposed on the side of the push plate 3 for removing dust on the acrylic plate 6 .

[0059] Further, the clamping assembly includes: four engaging plates 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com