Method for preparing 15-5PH stainless steel pipe

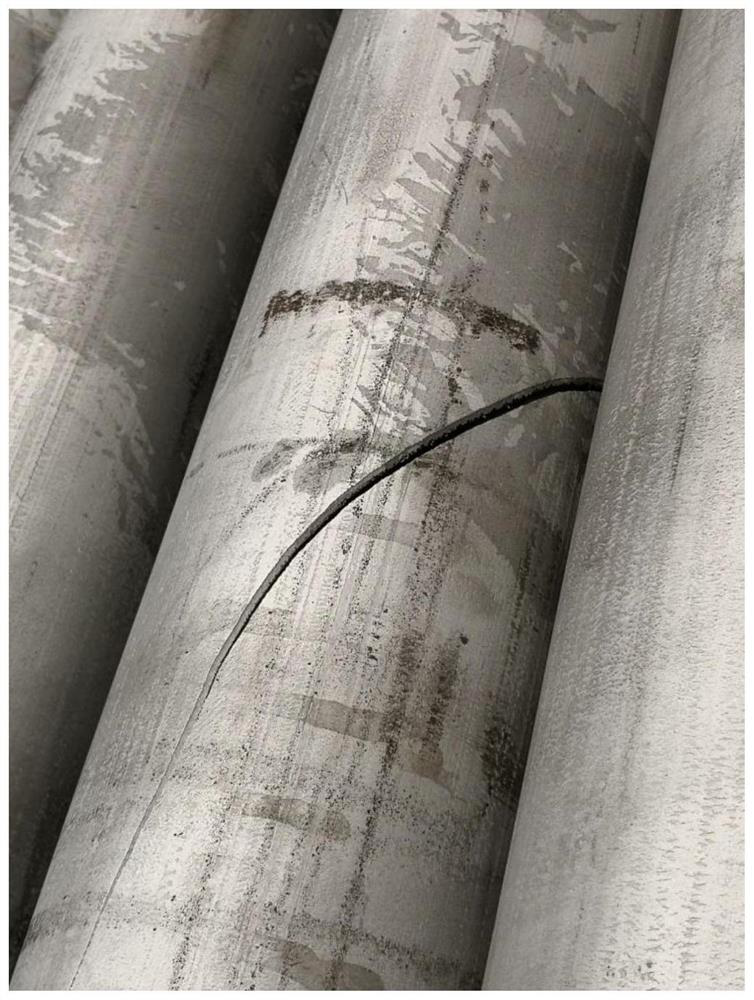

A stainless steel and pipe technology, applied in the field of pipe manufacturing, can solve problems such as easy occurrence of cracks, and achieve the effects of eliminating internal stress, low cost and improving elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] (1) Reaming: Heat the 15-5PH stainless steel blank with a through hole in the middle, put the heated blank in a vertical reaming cylinder, and use the reaming head to expand the small through hole in the middle of the blank from top to bottom, and then remove the blank from the reaming cylinder.

[0071] (2) Hot extrusion: The reamed 15-5PH stainless steel blank is thermoextruded plastic deformation treatment, and the high temperature 15-5PH stainless steel blank heated to 1200 ° C in the high temperature furnace is put into the cylindrical extrusion cylinder container with an extrusion die at the front end, and then the extrusion rod is extruded from the other end with thousands of tons of high pressure from the die hole to become an extrusion pipe (pipe thickness 30mm).

[0072] (3) Solution treatment: The extruded pipe after hot extrusion is cooled to 1050 ° C, and then quickly cooled to room temperature.

[0073] (4) Low temperature heat treatment: the room temperature ex...

Embodiment 2

[0077] (1) Reaming: Heat the 15-5PH stainless steel blank with a through hole in the middle, put the heated blank in a vertical reaming cylinder, and use the reaming head to expand the small through hole in the middle of the blank from top to bottom, and then remove the blank from the reaming cylinder.

[0078] (2) Hot extrusion: The 15-5PH stainless steel blank after reaming is thermoextruded plastic deformation treatment, and the high temperature 15-5PH stainless steel blank heated to 1200 ° C in the high temperature furnace is put into the cylindrical extrusion cylinder container with an extrusion die at the front end, and then the extrusion rod is extruded from the other end with thousands of tons of high pressure from the die hole to become an extrusion pipe (pipe thickness of 25mm), and the extruded pipe is cooled to room temperature.

[0079] (3) Solution treatment: The room temperature extruded pipe is heated to 1040 °C in a high-temperature furnace, insulation is 2min, an...

Embodiment 3

[0084] (1) Reaming: Heat the 15-5PH stainless steel blank with a through hole in the middle, put the heated blank in a vertical reaming cylinder, and use the reaming head to expand the small through hole in the middle of the blank from top to bottom, and then remove the blank from the reaming cylinder.

[0085] (2) Hot extrusion: The 15-5PH stainless steel blank after reaming is thermoextruded plastic deformation treatment, and the high temperature 15-5PH stainless steel blank heated to 1200 °C in the high temperature furnace is put into the cylindrical extrusion cylinder container with an extrusion die at the front end, and then the extrusion rod is extruded from the other end with thousands of tons of high pressure from the die hole to become an extrusion pipe (pipe thickness 27mm).

[0086] (3) Solid solution treatment: The extruded pipe after hot extrusion is cooled to 1060 ° C, and then the water is quickly cooled to room temperature.

[0087] (4) Low temperature heat treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com