Forming die for processing high-temperature-resistant double-lattice aluminum foil box

A technology for forming molds and aluminum foil boxes, which is applied to forming tools, manufacturing tools, household appliances, etc., can solve problems such as wasting time and reducing processing efficiency, achieve accurate positioning, improve processing efficiency, and ensure processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

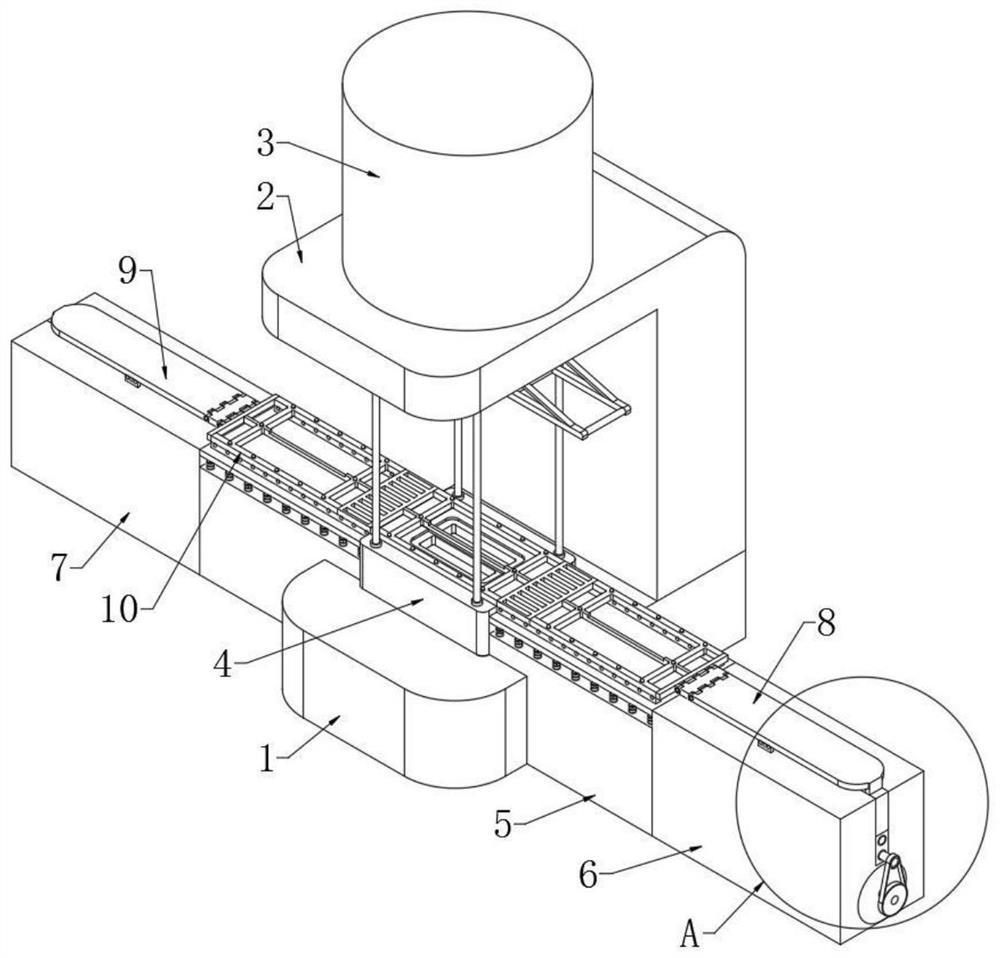

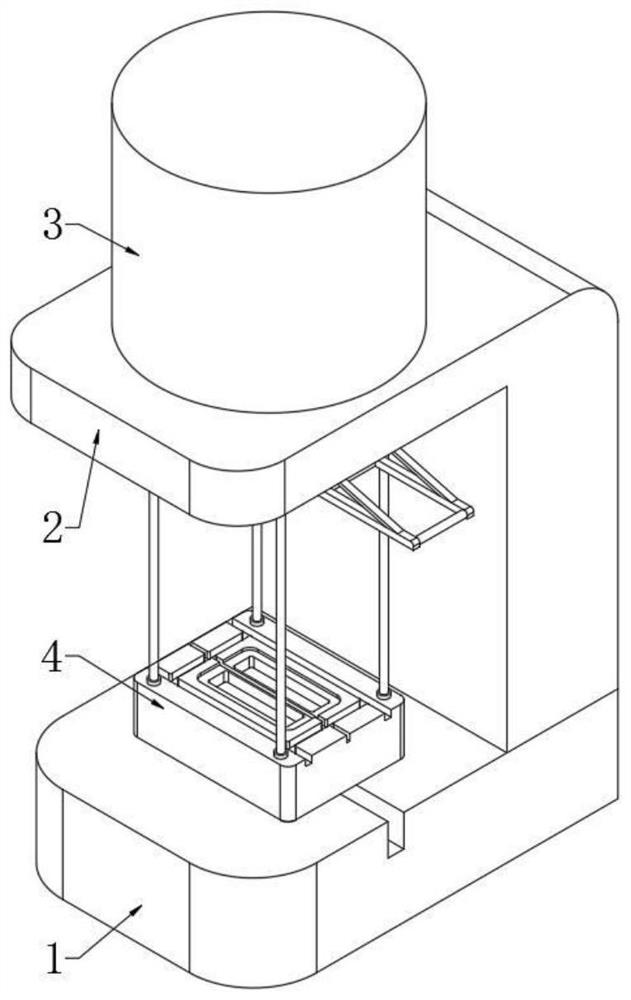

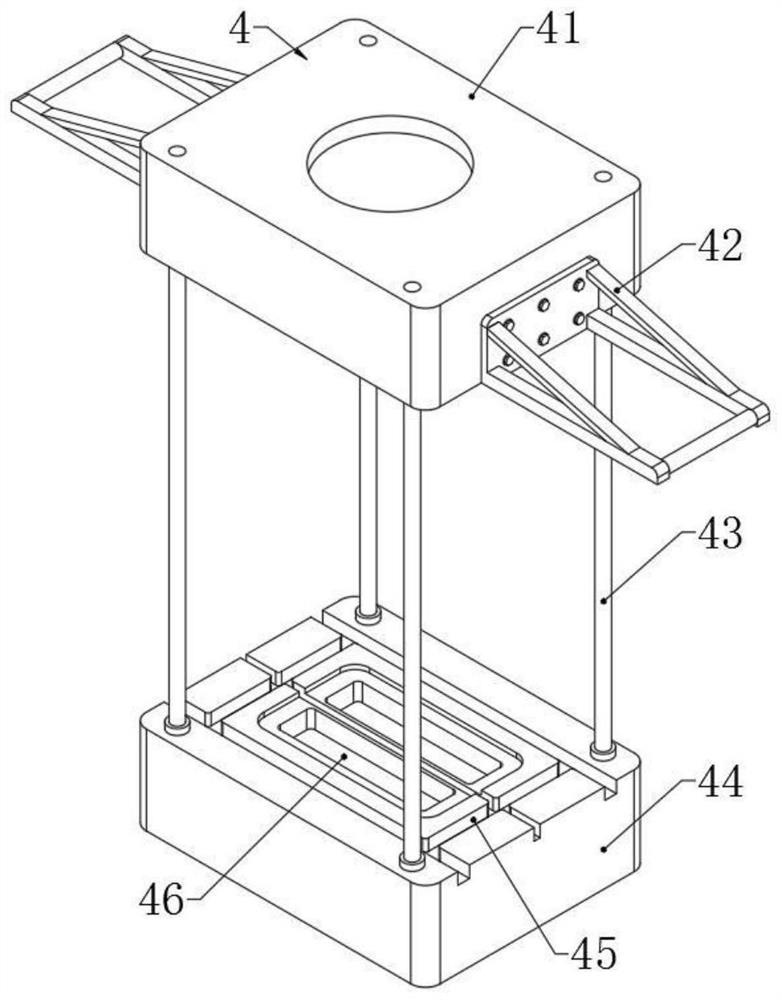

[0038] Place the aluminum foil box sheet on the top of the sheet transport assembly 10, and when the aluminum foil box sheet follows the sheet transport assembly 10 to move above the die 44, start the punching cylinder 3, and the punching cylinder 3 drives the punch 41 through the telescopic rod. Move downward, the punch 41 and the die 44 are clamped, and at the same time, the stabilizer 42 presses the material plate transport assembly 10, and presses the material plate transport assembly 10 to the inside of the adapter slot 45, so that the aluminum foil box plate falls off. At the top of the female die 44 , with the punching die 41 and the female die 44 being clamped, the aluminum foil box sheet material is punched into the aluminum foil box inside the forming groove 46 .

[0039]The two support assemblies are symmetrically arranged. The support assembly includes a support table 5. The two support tables 5 are fixedly installed on both sides of the support base 1. A connecting...

Embodiment 2

[0041] On the basis of the first embodiment, the stabilizing frame 42 exerts pressure on the material plate transportation assembly 10 , the material plate transportation assembly 10 moves downward, and the material plate transportation assembly 10 exerts pressure on the support slide, which in turn exerts pressure on the support plate 53 Pressure, the support plate 53 compresses the support spring 52 , so that the material plate transport assembly 10 can be kept stable during the working process, and can slide stably on the top end of the die 44 .

[0042] The first driving seat 6 includes a driving mounting seat 61 , which is fixedly installed on one side of the support table 5 , and a guide chute 62 is provided at the top of the driving mounting seat 61 . rod 63, and a transmission threaded rod 64 is rotatably installed inside the guide chute 62, the transmission threaded rod 64 is arranged below the limit sliding rod 63, and the transmission threaded rod 64 and the limit sl...

Embodiment 3

[0047] On the basis of Embodiment 1 and Embodiment 2, the material plate of the aluminum foil box is moved by the material plate transport assembly 10. First, the driving motor 65 is started. The driving motor 65 drives the transmission threaded rod 64 to rotate clockwise, and the transmission threaded rod 64 drives the connection. The sliding block 81 and the second sliding block move to one side of the support base 1 , and then drive the first driving connecting plate 8 and the second driving connecting plate 9 to move synchronously, and the material plate carrier 101 moves the aluminum foil box material plate to the die 44 At the top of the , the drive motor 65 stops rotating, starts the punching cylinder 3, and makes the punch 41 and the concave die 44 die;

[0048] At the same time, place an aluminum foil box material plate on the top of the two material plate carriers 101 on one side, and then start the driving motor 65, and the driving motor 65 drives the transmission th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com