High-performance lock riveting rivet for automobile and press riveting upper die of high-performance lock riveting rivet

A high-performance, locking riveting technology, applied in the direction of rivets, screws, connecting components, etc., can solve the problems that the locking rivets cannot be fully fitted, it is difficult to achieve anti-rotation effect, and the air tightness is poor. The effect of enhanced capacity and improved riveting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

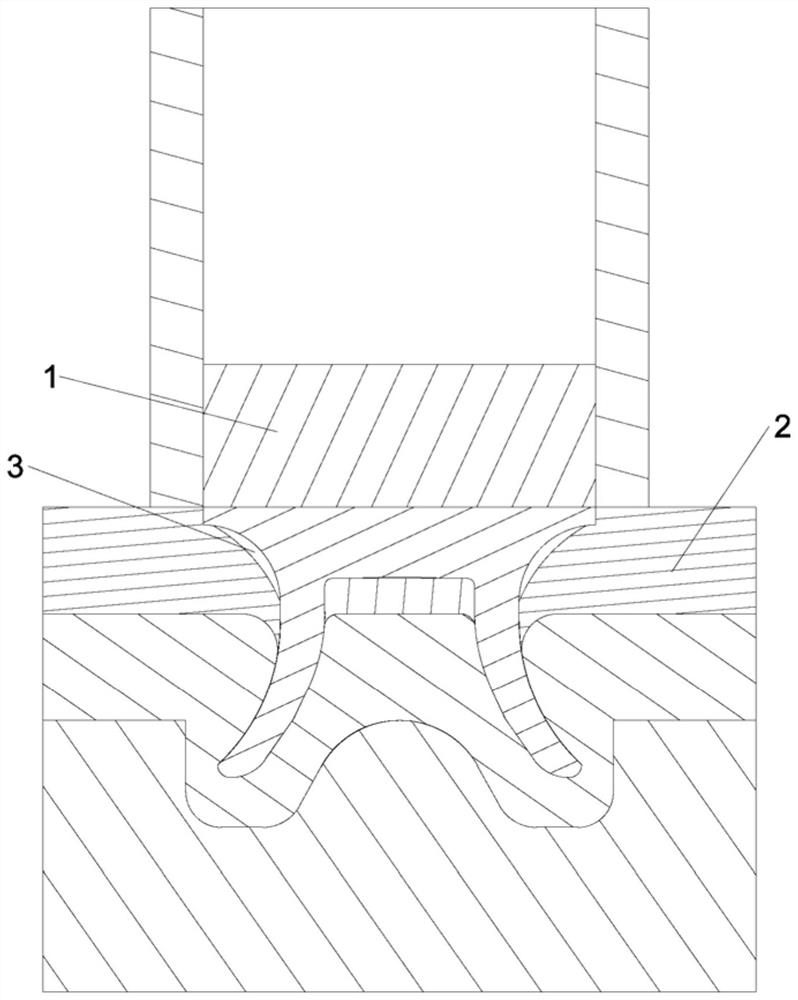

[0041] In order to solve the technical problems, technical solutions and beneficial effects of the present invention to be more clear and understandable, the following in conjunction with the accompanying drawings and embodiments, the present invention will be further elaborated in detail. It should be understood that the specific embodiments described herein are only used to explain the present invention and are not intended to qualify the present invention.

[0042] The claims of the present invention, the description and the above-mentioned drawings, unless otherwise expressly qualified, such as the use of the terms "first", "second" or "third", etc., are intended to distinguish different objects, rather than to describe a particular order.

[0043]In the claims of the present invention, the specification and the above-mentioned drawings, unless otherwise expressly defined, for azimuth words, such as the use of the terms "center", "horizontal", "vertical", "vertical", "top", "b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com