Brass alloy and preparation method thereof

A technology of brass alloy and brass, which is applied in the field of brass alloy and its preparation, can solve the problems of poor cold riveting performance of materials, and achieve the effects of improving riveting performance, improving electrical conductivity, and increasing critical current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

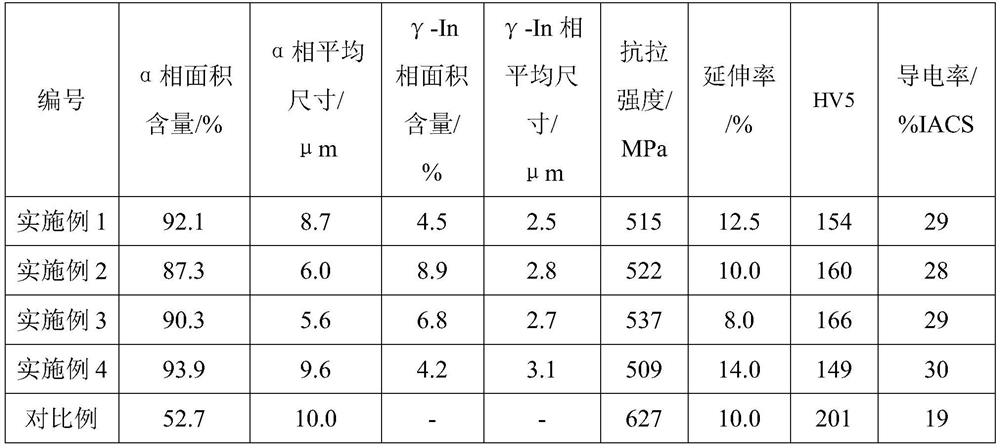

Embodiment 1

[0037]1) Melting: According to the required composition ratio, the raw materials used include electrolytic plates, indium ingots, tin ingots, pure nickel, zinc ingots, and lanthanum-cerium alloys. The raw materials are sequentially added into the industrial frequency furnace to raise the temperature, and the melting temperature is controlled at 990°C.

[0038] 2) Casting: The horizontal continuous casting process is used to produce ingots, in which the traction pitch: 35mm; reverse thrust pitch: 2mm; traction speed: 12mm / s; reverse thrust speed: 2mm / s. Ingot specification: φ145mm.

[0039] 3) Extrusion: the ingot is heated before extrusion, and the heating process is carried out in three stages. Preheating stage: temperature controlled at 300°C, heating time 25min; heating stage: temperature controlled at 600°C, heating time 30min; holding stage: 710°C, heating time 30min. Use the 1800t extruder to extrude the blank with the specification of φ8mm.

[0040] 4) Disk drawing: ...

Embodiment 2

[0045] 1) Melting: According to the required composition ratio, the raw materials used include electrolytic plates, indium ingots, tin ingots, pure nickel, zinc ingots, and metal magnesium. The raw materials are sequentially added into the power frequency furnace to raise the temperature, and the melting temperature is controlled at 980°C.

[0046] 2) Casting: The horizontal continuous casting process is used to produce ingots, in which the traction pitch: 36mm; reverse thrust pitch: 2mm; traction speed: 14mm / s; reverse thrust speed: 2mm / s. Ingot specification: φ145mm.

[0047] 3) Extrusion: the ingot is heated before extrusion, and the heating process is carried out in three stages. Preheating stage: temperature controlled at 280°C, heating time 25min; heating stage: temperature controlled at 580°C, heating time 30min; holding stage: 680°C, heating time 20min. Use the 1800t extruder to extrude the blank with the specification of φ7.5mm.

[0048] 4) Disk drawing: After pick...

Embodiment 3

[0053] 1) Melting: According to the required composition ratio, the raw materials used include electrolytic plates, indium ingots, tin ingots, pure nickel, zinc ingots, metal manganese and copper-zirconium alloys. The raw materials are sequentially added into the industrial frequency furnace to raise the temperature, and the melting temperature is controlled at 1000°C.

[0054] 2) Casting: The horizontal continuous casting process is used to produce ingots, in which the traction pitch: 38mm; reverse thrust pitch: 2mm; traction speed: 12mm / s; reverse thrust speed: 2mm / s. Ingot specification: φ145mm.

[0055] 3) Extrusion: the ingot is heated before extrusion, and the heating process is carried out in three stages. Preheating stage: temperature control at 300°C, heating time 30min; heating stage: temperature control at 580°C, heating time 20min; holding stage: 680°C, heating time 25min. Use the 1800t extruder to extrude the blank with the specification of φ7.8mm.

[0056] 4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com