Laminated slab forming device

A technology of forming device and laminated plate, which is applied to surface layering device, ceramic forming machine, manufacturing tool, etc., can solve the problems of time-consuming and labor-intensive, and the flatness is difficult to control, and achieve the effect of flexible movement and improved troweling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

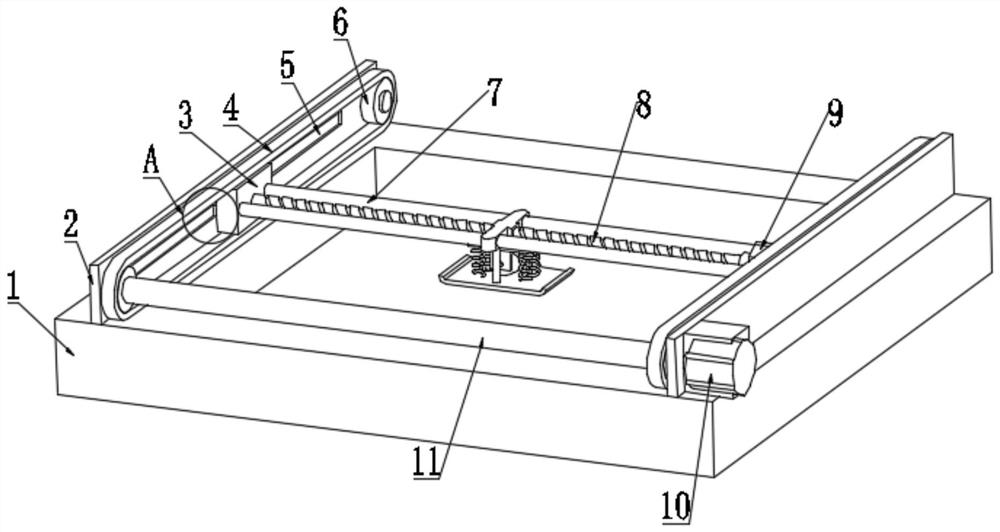

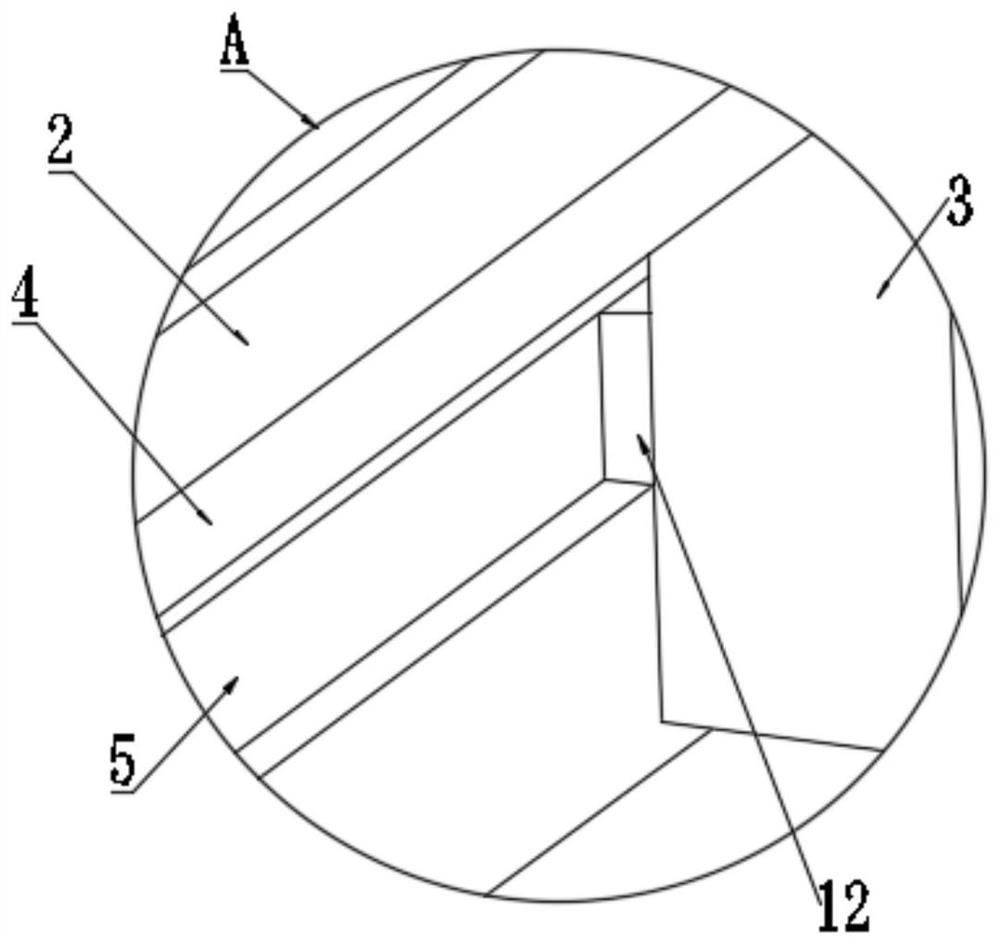

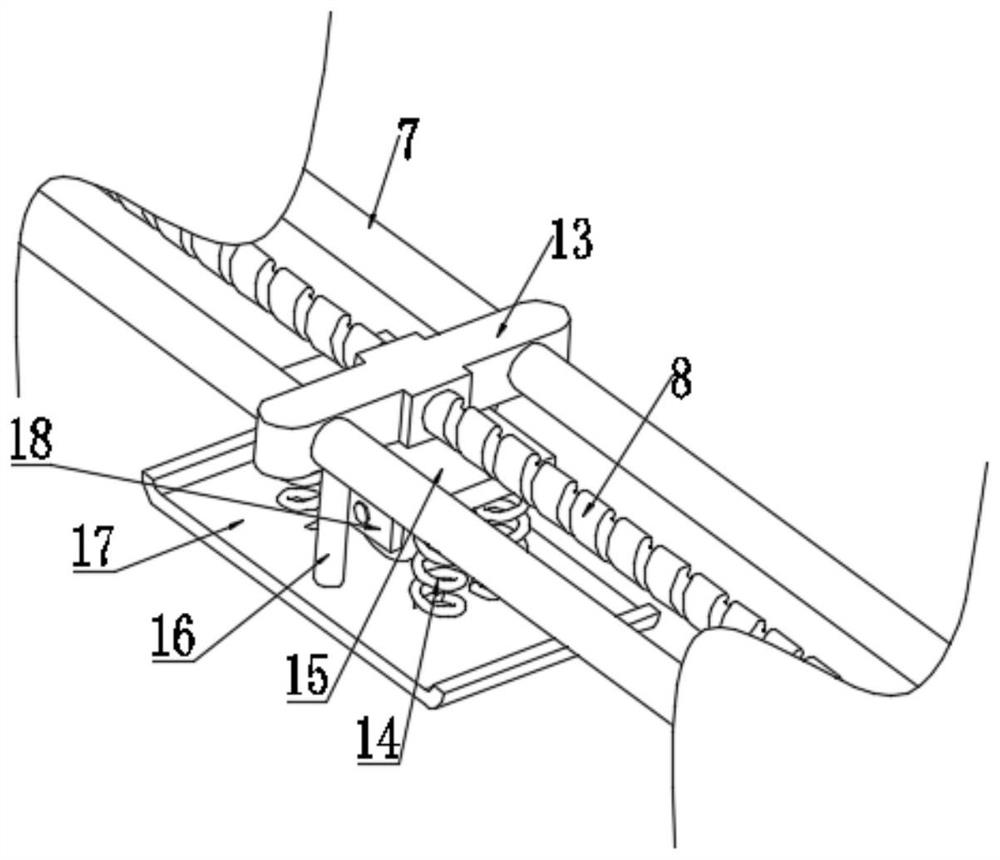

[0032] refer to Figure 1 to Figure 4 As shown, the figure shows a laminated plate forming device. The laminated plate forming device comprises a watering pool 1, the top outer wall of the watering pool 1 is fixedly connected with a rectangular plate 2, the rectangular plates 2 are symmetrically distributed, and the side walls on the opposite sides of the two rectangular plates 2 are respectively provided with The connecting block 3, wherein one side wall of one connecting block 3 is fixedly connected with a first motor, one end of the output shaft of the first motor is fixedly connected with a threaded rod 8, and the other connecting block 3 is rotatably connected with the threaded rod 8 through a bearing The outer wall of the threaded rod 8 is screwed with a moving block 13 , the bottom of the moving block 13 is fixedly connected with a mounting plate 15 , and a leveling unit is provided on the lower side of the mounting plate 15 . The leveling unit realizes automatic level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com