A kind of down seamless shaping heat sealing equipment

A heat-sealing equipment and seamless technology, applied in the field of down processing equipment, can solve the problems of fiber and down and two-layer fabrics that are not easy to bond, reduce performance, and affect processing quality, so as to improve work efficiency and performance, improve The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

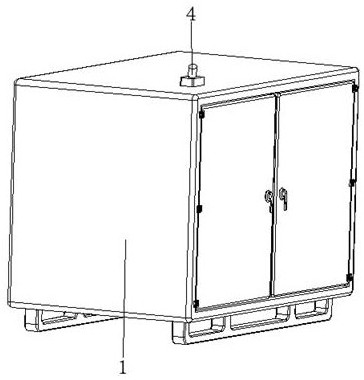

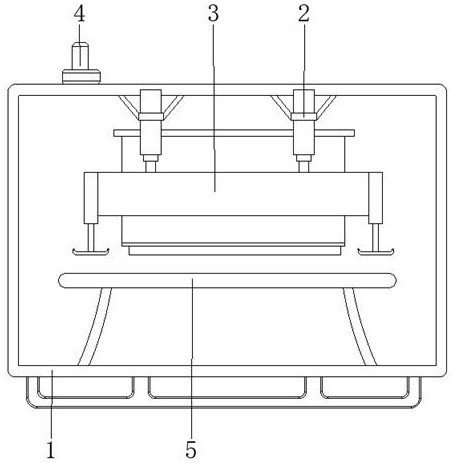

[0034] see Figure 1-6 , the present invention provides a technical solution: a down seamless shaping heat sealing equipment, comprising a body 1, a lifting mechanism 2, a heat sealing device 3, the top of the lifting mechanism 2 is fixedly connected with the top of the inner wall of the body 1, and the heat sealing device 3 set at the output end of the lifting mechanism 2;

[0035] The top side of the body 1 is provided with an alarm 4, and a workbench 5 is set at the bottom center of the inner wall of the body 1. The raw materials to be processed are placed on the workbench 5, and the height of the heat sealing device 3 is adjusted by the lifting mechanism 2. Adjust to make it lift to an appropriate position, and use the heat sealing device 3 to perform the heat sealing work, and use the support of the workbench 5 to the heat sealing device 3, and combine the action force and the reaction force, so that the whole device can be used to seal the fabric. Pushing and finishing ...

Embodiment example 2

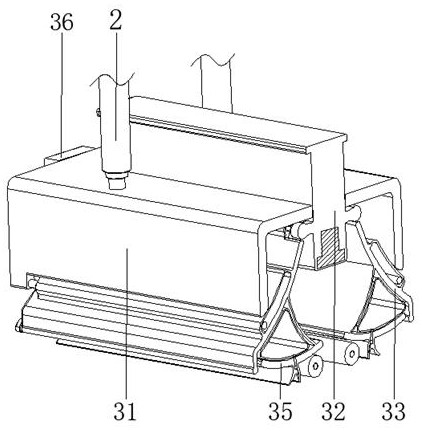

[0037] The heat sealing device 3 is provided with a U-shaped casing 31, a heating strip 32, an arc surface connecting plate 33, a tension spring 34, an anti-folding device 35, and a limiting device 36. The opening of the U-shaped casing 31 is downward and the top is connected to the lifting mechanism. The output end of 2 is fixedly connected, the surface of the heating strip 32 is slidably connected to the top central position of the U-shaped shell 31, the surface side of the arc surface connecting plate 33 is slidably connected to the bottom end of the U-shaped shell 31, and the arc surface connecting plate The top of 33 is hinged with the surface of the heating strip 32, the tension spring 34 is arranged between the top of the inner wall of the U-shaped shell 31 and the two sides corresponding to the surface of the arc connecting plate 33, and the anti-fold device 35 is arranged on the arc connecting plate 33. At the bottom end, the limiting device 36 is arranged on the surfa...

Embodiment example 3

[0041] The limiting device 36 is provided with a rectangular shell 361 , a curved elastic member 362 , and a pressing device 363 . The top is fixedly connected, and the pressing device 363 is arranged on the bottom of the rectangular shell 361 .

[0042] The pressing device 363 is provided with a sliding rod 3631, a connecting head 3632, and a pressing piece 3633. The sliding rod 3631 is slidably connected to the bottom center of the rectangular shell 361, and the connecting head 3632 is arranged inside the rectangular shell 361 and is fixedly connected to the top of the sliding rod 3631 , the top of the connecting head 3632 is fixedly connected with the bottom end of the curved elastic member 362 , and the pressing member 3633 is fixed on the bottom end of the sliding rod 3631 .

[0043] The bottom of the rectangular shell 361 is provided with a sliding hole that is adapted to the sliding rod 3631, the end of the pressing member 3633 is set to be curved upward, and the limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com