New energy automobile motor

A new energy vehicle, brush technology, applied in the direction of motors, electric vehicles, vehicle components, etc., can solve the problems of accelerating the internal oxidation of the motor, unable to achieve rapid cooling, and unable to meet the internal heating of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

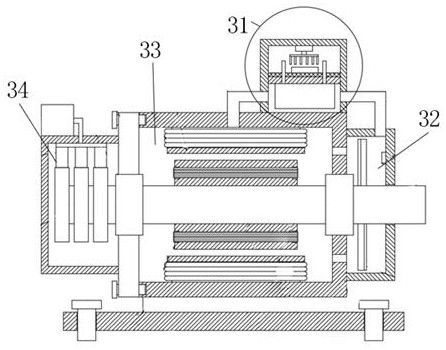

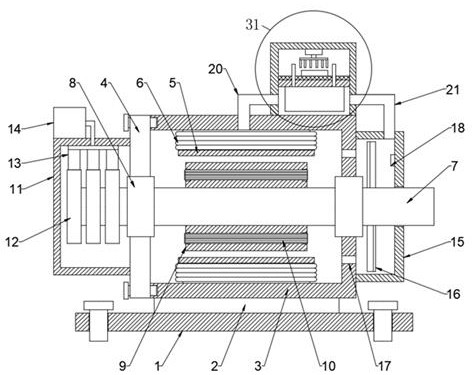

[0038] This embodiment provides a new energy vehicle motor, refer to figure 1 and 2 , this embodiment includes a first conduit 20 , a second conduit 21 , a temperature control module 31 , a circulation module 32 , a rotating module 33 and a rotating shaft 7 .

[0039] refer to figure 2 , the circulation module 32 includes the casing 15 and the fan blade 16 . The casing 15 is provided with a fan blade 16, the fan blade 16 is mounted on the rotating shaft 7, the rotating shaft 7 movably runs through the rotating module 33, the rotating module 33 is provided with a through hole 17, and the through hole 17 communicates with the rotating mold The cavity of group 33 and the cavity of housing 15.

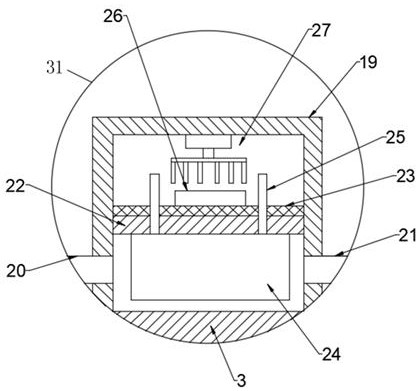

[0040] refer to image 3 , the temperature control module 31 includes the partition 22 , the temperature control plate 24 , the antifreeze, the box 19 and the temperature control module 26 . The partition 22 divides the box body 19 into an upper cavity and a lower cavity. Both sides...

Embodiment 2

[0045] On the basis of Embodiment 1, the new energy vehicle motor of this embodiment further includes a base plate 1 and a support block 2. During application, a bearing 8 is provided on the outer periphery of the rotating shaft 7, and the rotating shaft 7 is rotatably connected to the rotating module 33 through the bearing 8 , the rotating module 33 is installed on the support block 2 , and the support block 2 is installed on the base plate 1 .

[0046] The new energy vehicle motor in this embodiment further includes a control unit 14 and a brush module 34 , and introduces the rotation module 33 , the brush module 34 , the temperature control module 31 and the circulation module 32 in detail.

[0047] refer to figure 2 , the brush module 34 includes the housing 11 , the collector ring 12 and the brush 13 .

[0048] The control unit 14 is provided on the housing 11 , and the control unit 14 is connected to the brush 13 , so that the brush 13 is energized.

[0049] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com