Mining truck capable of running in two directions

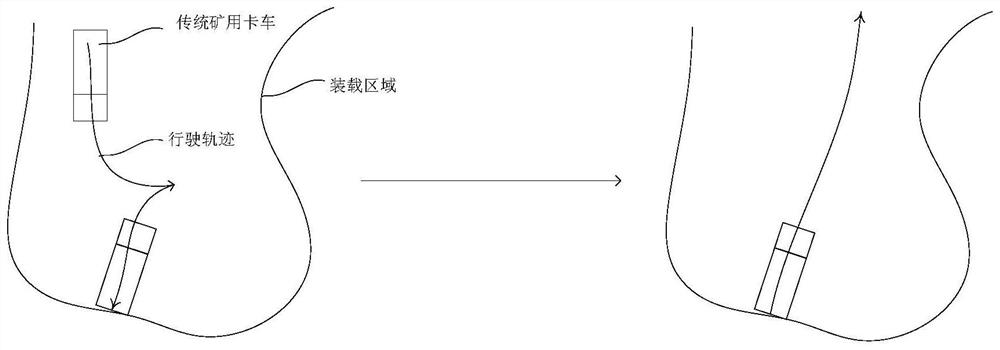

A technology for mines and trucks, applied to electric vehicles, vehicle components, climate sustainability, etc., can solve problems such as long time and impact on loading operation efficiency, and achieve the effect of improving loading efficiency and reducing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

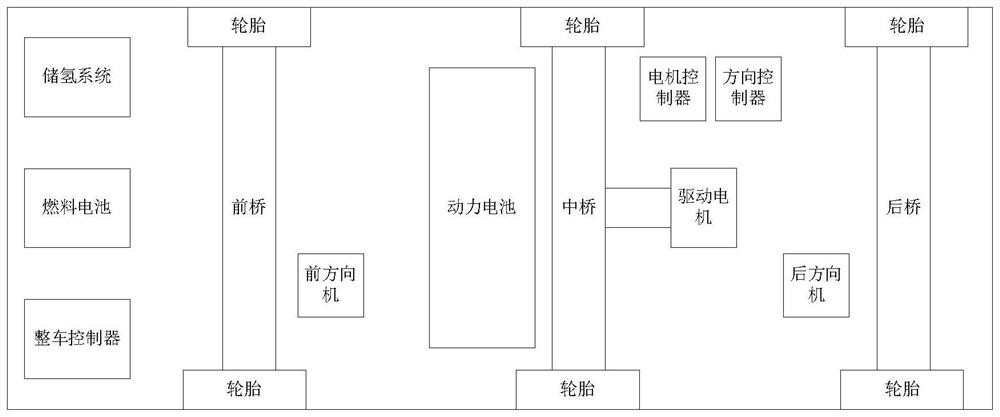

[0042] as Figure 2 As shown, embodiments of the present invention provides a two-way driving mining truck, comprising a power battery, front drive axle, middle drive axle, drive motor, rear drive axle and vehicle controller.

[0043] The front drive axle is set to the front steering machine;

[0044] The power battery provides kinetic energy to the drive axle in the drive motor by the drive motor;

[0045] The rear drive axle is set up with a rear directional machine;

[0046] The vehicle controller is used to control the drive motor, the forward steering machine and the rear directional motor, to achieve two-way driving of the mining truck.

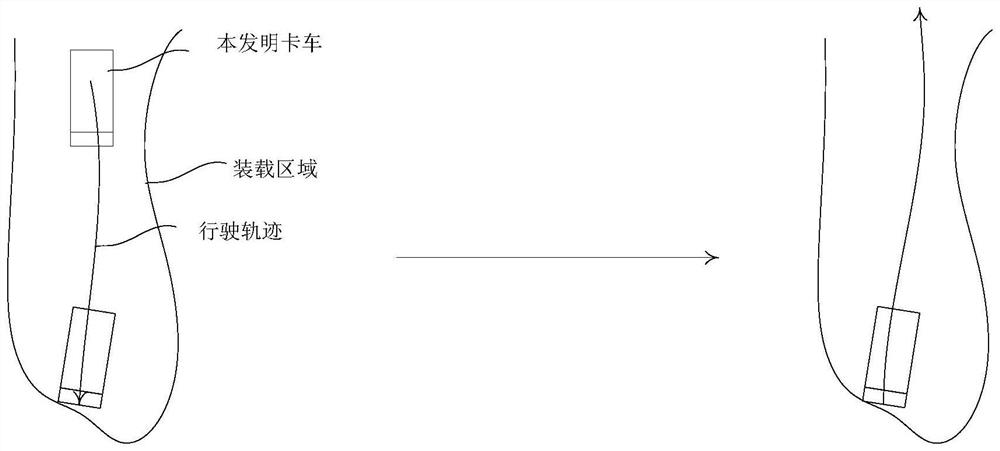

[0047] Embodiments of the present invention by designing a two-way driving power and steering system, so that the mining truck in the mining area when loading operations, without the need to make a U-turn, greatly reducing the loading area width requirements, but also greatly improve the loading efficiency.

[0048] Specifically, mining truc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com