Sucking disc, film adding device and filling production line

A technology of membrane device and suction cup, which is applied in the direction of packaging, etc., can solve the problems that affect the product qualification rate, product sealing is not strict, and affect the appearance of the product, so as to improve the appearance appearance, improve the heat sealing effect, and expand the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

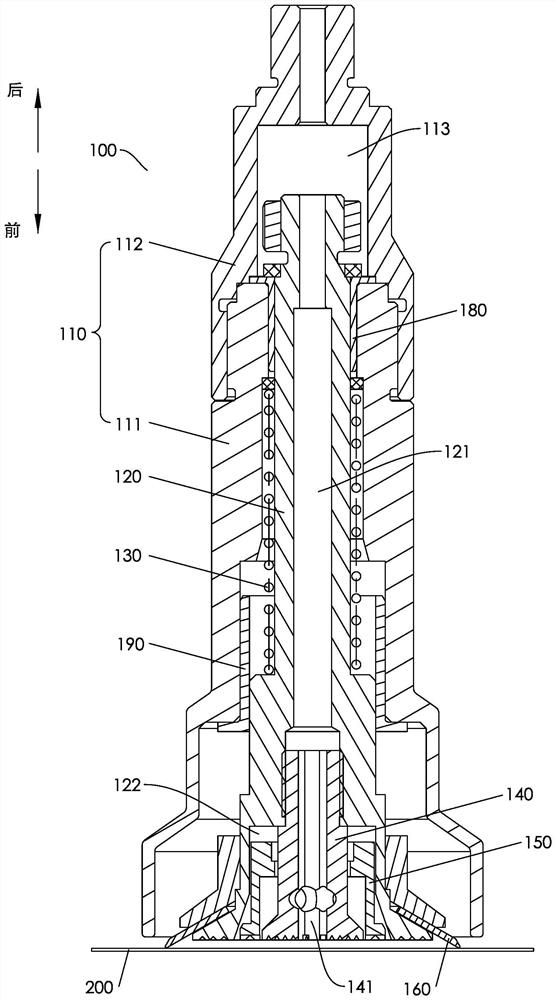

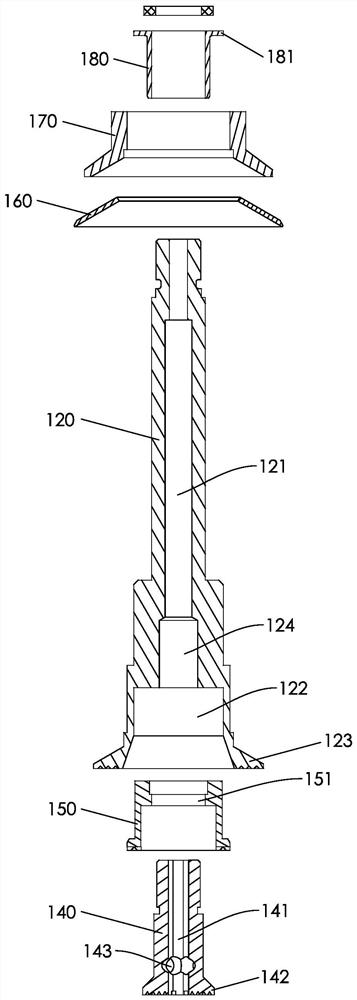

[0030] as Figure 1 、 Figure 2 As shown, an embodiment of the present invention provides a suction cup 100 for aspirating the diaphragm 200 and placing the diaphragm 200 at the mouth of the cup body, the suction cup 100 includes a hollow housing 110, an inner tube 120 may be moved forward and backwards within the housing 110 and a spring 130 is located outside the inner tube 120 for driving the internal tube 120 to reset, the rear end of the housing 110 is provided with a ventilation chamber 113, the inner tube 120 is provided with an air duct 121 in communication with the ventilation chamber 113. Suction cup 100 further includes a suction nozzle 140, a vacuum-breaking member 150 and a shaping disc 160, the front end of the inner tube 120 is provided with a cavity 122, the suction nozzle 140 and the broken vacuum member 150 is located in the cavity 122 and the vacuum-breaking member 150 sets are disposed on the outside of the suction nozzle 140, the suction nozzle 140 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com